An Artificial Accelerated Simulation Method for Natural Aging of Rapidly Cooled Steel Plates

A natural aging and rapid cooling technology, applied in the field of steel rolling, can solve the problems of less attention and lack of research on the natural aging of steel plates, and achieve the effect of shortening the time for aging performance changes, low equipment requirements, and conducive to production rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of artificial acceleration simulation method of natural aging of fast cooling steel plate provided by the present invention comprises the following steps:

[0034] (1) The selected steel plate is plain carbon steel, and its chemical composition (mass percentage) is C: 0.13% to 0.25%; Si: 0.10% to 0.40%; Mn: ≤1.10%; P: ≤0.015%; S: ≤ 0.010%; Als: 0.01% ~ 0.05%; N: 0.002% ~ 0.01%; the balance is Fe and unavoidable impurities;

[0035] (2) The thickness of the selected steel plate is 10-50mm;

[0036] (3) Carry out the controlled rolling and controlled cooling process. The parameters in the controlled rolling and controlled cooling process are: heating temperature is 1150-1250°C; final rolling temperature is 810-870°C; cooling rate is 10-30°C / s; 540-600°C; straightening temperature is 520-580°C;

[0037] (4) Adopt an orthogonal control process that artificially accelerates to simulate natural aging, specifically: the heating temperature is 150-200°C, the holding ti...

Embodiment 2

[0050] Embodiment 2: a method for artificially accelerating simulated natural aging control of a rapidly cooled steel plate, comprising the following steps:

[0051] (1) The mass percentage of the chemical composition of the selected steel plate is: C: 0.17%, Mn: 0.92%, P: 0.010%, S: 0.008%, Si: 0.25%, Als: 0.030%, N: 0.0050%, and the balance It is Fe and unavoidable impurities.

[0052] (2) The thickness of the steel used is 14mm.

[0053] (3) Carry out the controlled rolling and controlled cooling process. The parameters in the controlled rolling and controlled cooling process are: heating temperature: 1205°C, final rolling temperature: 862°C, cooling rate: 18°C / s, reddening temperature 597°C, straightening temperature : 585°C.

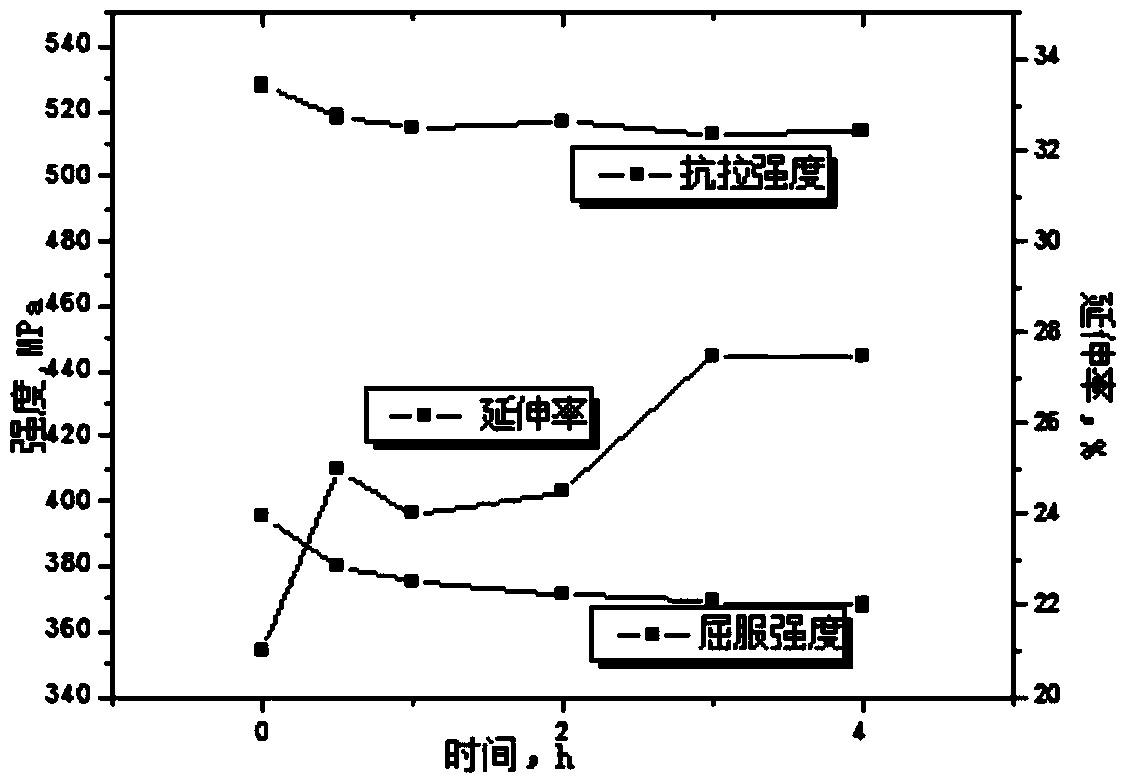

[0054] (4) Orthogonal control process using artificial acceleration to simulate natural aging: temperature selection 150, 200 ℃, holding time selection 0.5, 1h, 2h, 3h, 4h, test the yield strength, tensile strength and elongation of the steel plat...

Embodiment 3

[0060] Embodiment 3: A method for artificially accelerating and simulating natural aging control of rapidly cooled steel plates, comprising the following steps: (1) The mass percentages of the chemical components of the selected steel plates are: C: 0.162%, Mn: 0.95%, P: 0.011%, S: 0.007%, Si: 0.26%, Als: 0.033%, N: 0.0055%, and the balance is Fe and unavoidable impurities.

[0061] (2) The thickness of the steel used is 20mm.

[0062] (3) Carry out the controlled rolling and controlled cooling process. The parameters in the controlled rolling and controlled cooling process are: heating temperature: 1215°C, final rolling temperature: 852°C, cooling rate: 22°C / s, reddening temperature 585°C, straightening temperature : 580°C.

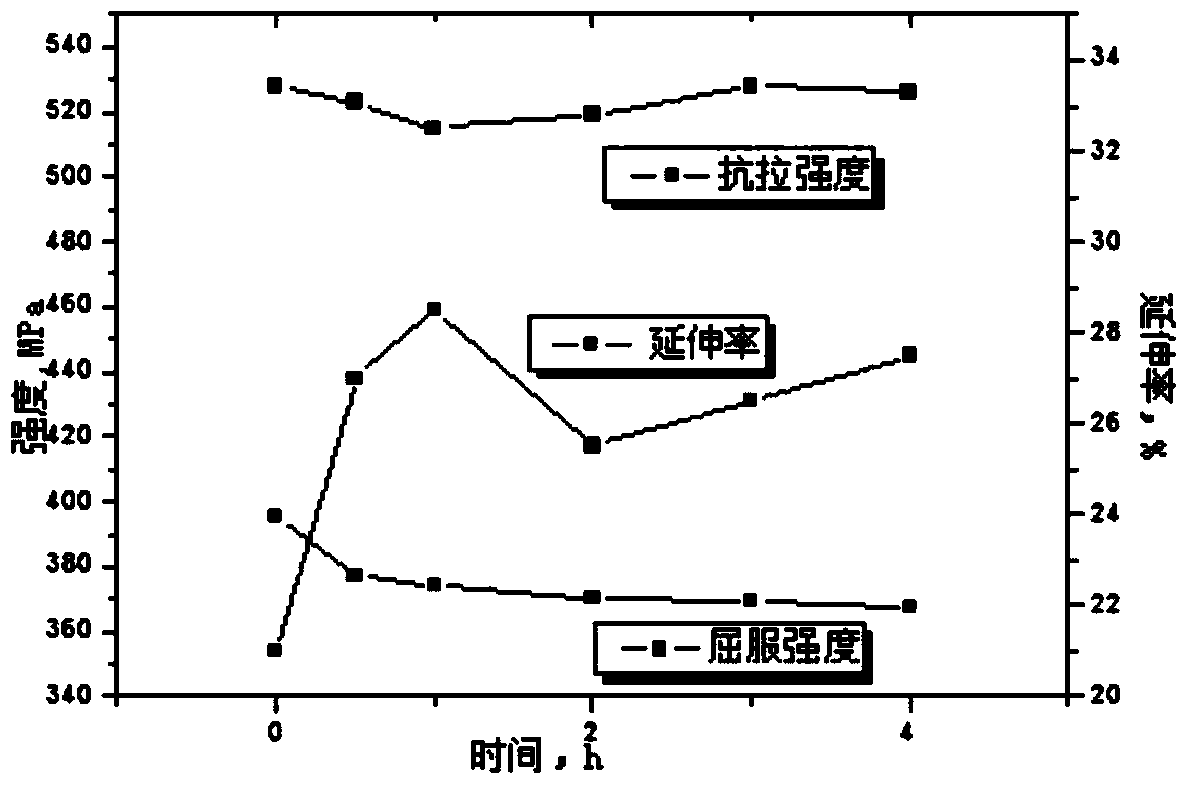

[0063] (4) Orthogonal control process using artificial acceleration to simulate natural aging: temperature selection 150, 200 ℃, holding time selection 0.5, 1h, 2h, 3h, 4h, test the yield strength, tensile strength and elongation of the steel plate.

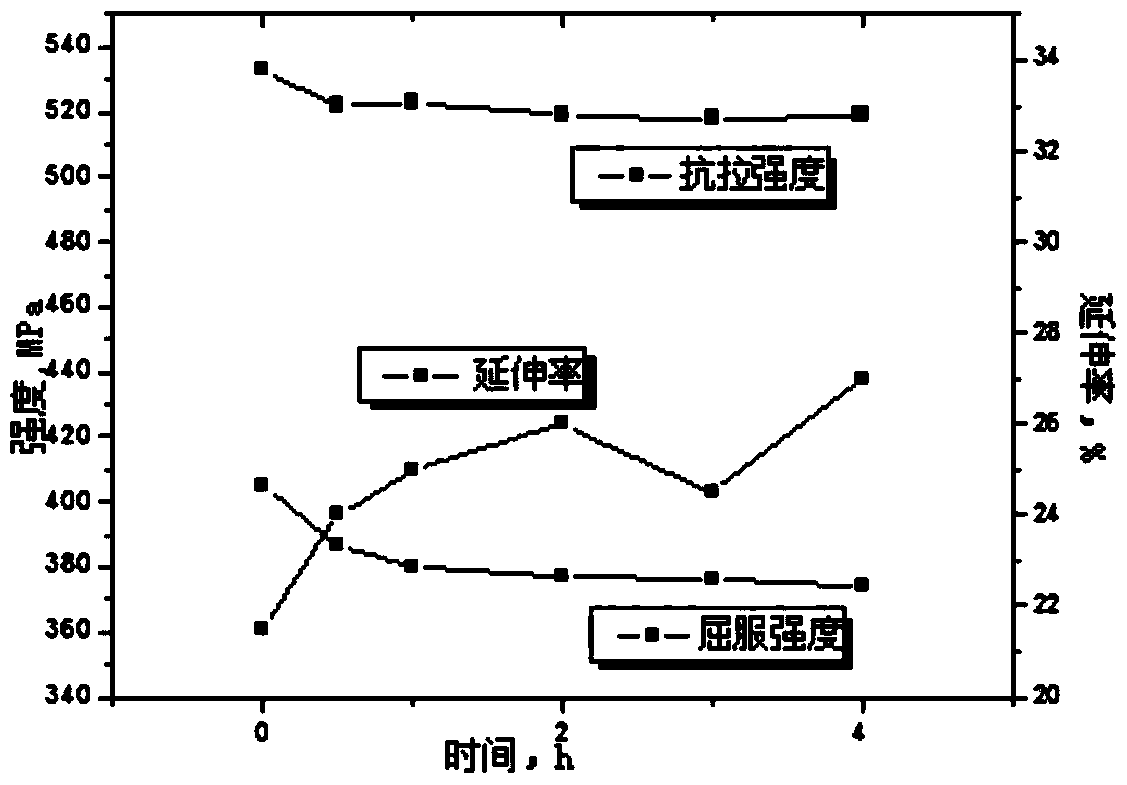

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com