Silicon carbide preparation method

A technology of silicon carbide and carbon source, applied in the direction of silicon carbide, carbide, etc., can solve the problems of high pollution of silicon carbide and low purity of silicon carbide, and achieve the effects of improving purity, fast reaction speed and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of silicon carbide uses silicon dioxide and pure carbon as raw materials. The silicon dioxide is reduced by carbon at high temperatures to produce solid silicon carbide and gaseous carbon dioxide, and ash, impurity gas and powder are released. The temperature and speed of this reaction are determined by the size of the silica and the distance between the silica and the carbon element of the reducing material: the smaller the silica and the shorter the distance between the silica and the carbon element, the higher the temperature required for the reaction. The lower, the faster.

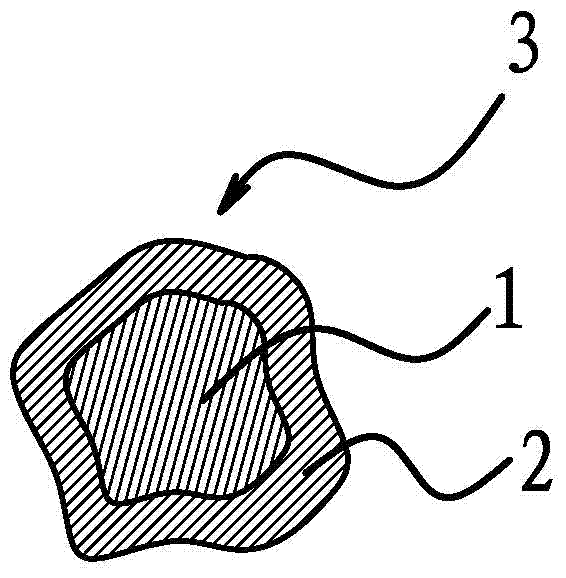

[0043] To this end, the present invention adopts the following steps to realize the production of silicon carbide: completely wrap the silica 1 with a carbon source containing carbon and make raw material particles 3; and react the raw material particles 3 at high temperature to generate silicon carbide. The main component of silica 1 is silicon dioxide. In this example, si...

Embodiment 2

[0058] According to our experiments, although the impurities contained in the silicon carbide produced by the reaction are mainly derived from silicon dioxide and carbon element raw materials, when carbon is used as a heating element, it also includes a carbon electrode. In fact, the ash produced after the reaction has an effect on the purity of silicon carbide. The impact is very big. That is, in the reducing atmosphere formed by heating the carbon element, while the silica is reduced, the ash as the residue is also reduced by the surrounding reducing atmosphere, and the generated reducing element diffuses and penetrates into the generated silicon carbide, and the generated silicon carbide Silicon carbide pollution results in low purity of silicon carbide.

[0059] In this case, the present invention includes the use of equipment equipped with plasma generator 4 to produce silicon carbide. The plasma generator 4 can generate a high temperature of 3000 degrees Celsius. The raw ...

Embodiment 3

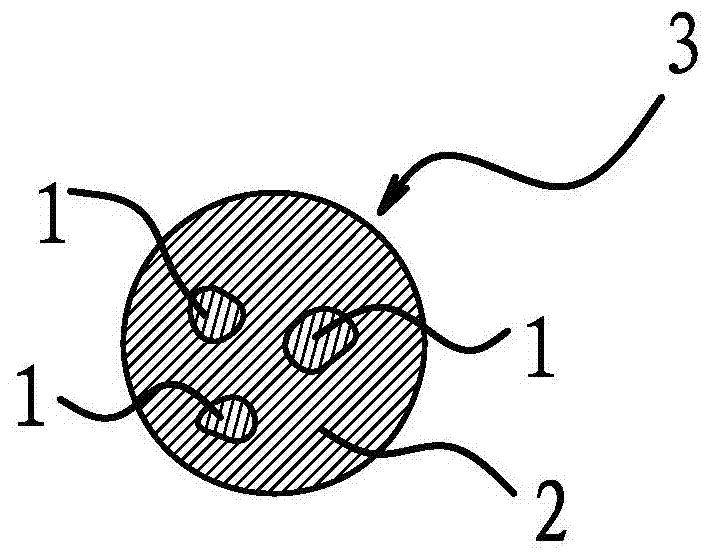

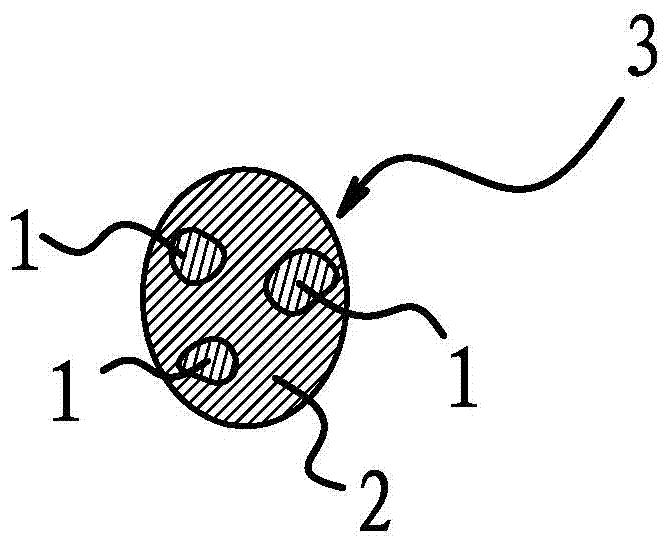

[0066] When the plasma generator 4 is used as a high-temperature source to heat and prepare silicon carbide, the present invention further proposes a method for preparing silicon carbide in a variety of raw material forms.

[0067] A method for preparing silicon carbide includes directly putting carbon source 2 and silica 1 or metallic silicon or a mixture of both into a plasma flame for heating reaction at the same time, thereby generating silicon carbide. In this method, the carbon source 2 and the silica 1 or the metallic silicon are directly injected into the plasma flame through their respective channels at the same time, and silicon carbide can be generated as long as the two are fully mixed after being injected.

[0068] Specifically, the carbon source 2 is a substance whose carbon element undergoes a reduction reaction or a carbonization reaction in the reaction with silicon element. The carbon source 2 is a gaseous carbon source 2, and the gaseous carbon source 2 is one or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com