Carrier-roller gravitational material conveyer

A technology of conveying device and idler roller, which is applied in the direction of transportation, packaging, roller table, etc., which can solve the problems of large safety hazards, damage to lifting equipment, and high labor intensity of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

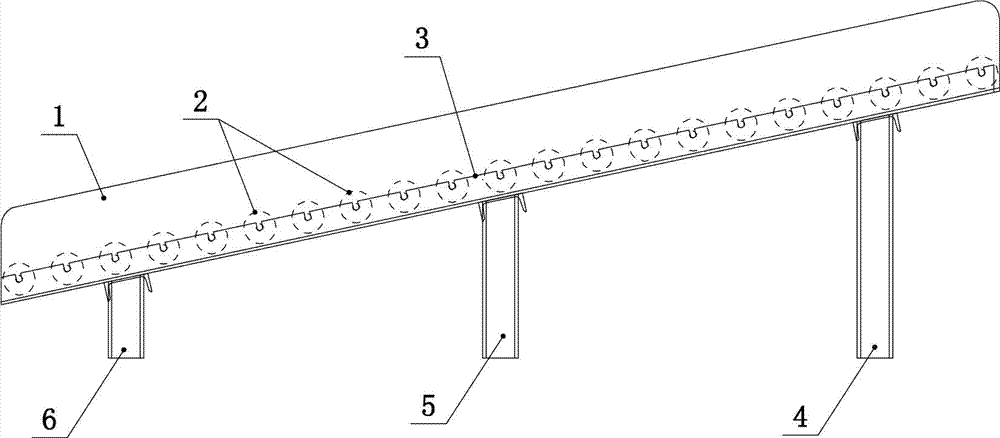

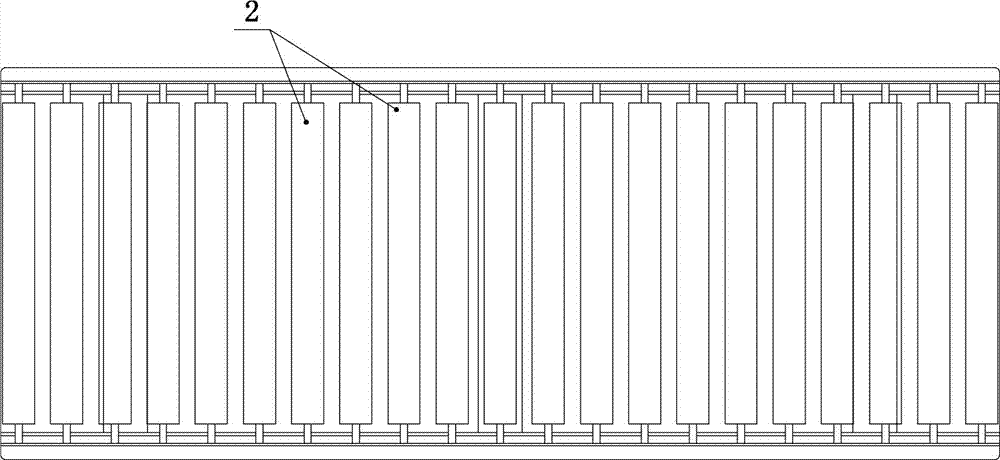

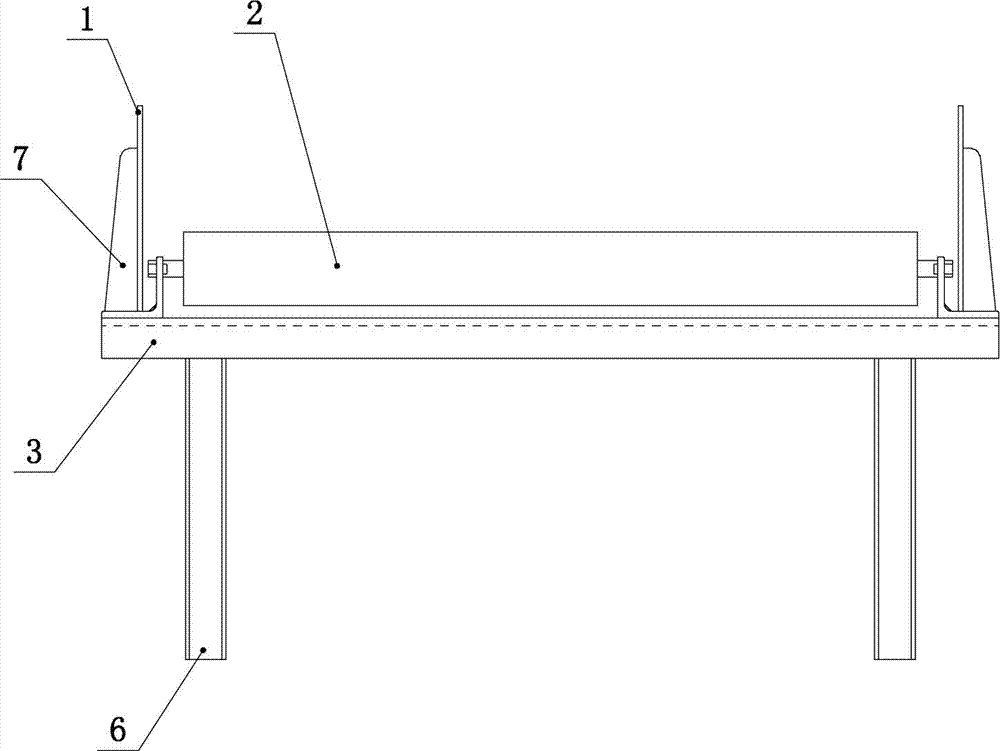

[0016] A roller-type material self-weight conveying device, such as figure 1 , figure 2 with image 3 As shown, it includes a front support leg 6 and a rear support leg 4, and the upper ends of the front support leg 6 and the rear support leg 4 are fixedly connected with a frame 3, and the frame 3 is obliquely arranged. The idler 2 is set up and down along the inclined surface of the frame 3.

[0017] In this embodiment, a baffle 1 is fixedly connected to the frame 3 outside both ends of the idler 2 , and the baffle 1 and the idler 2 are perpendicular to each other. The outer side of the baffle 1 is fixedly connected with a reinforced support plate 7 , the reinforced support plate 7 is perpendicular to the baffle 1 , and the lower edge of the reinforced support plate 7 is fixedly connected with the frame 3 . Auxiliary support legs 5 are fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com