Pneumatic operation and remote monitoring system for tanker filling and exhausting

A remote monitoring system and tanker technology, which is applied to motor vehicles, goods transport vehicles, and vehicles used for freight, can solve problems such as poor safety and reliability, reduced flow at the oil discharge port, and low work efficiency to achieve work efficiency The effect of high speed, speed improvement and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

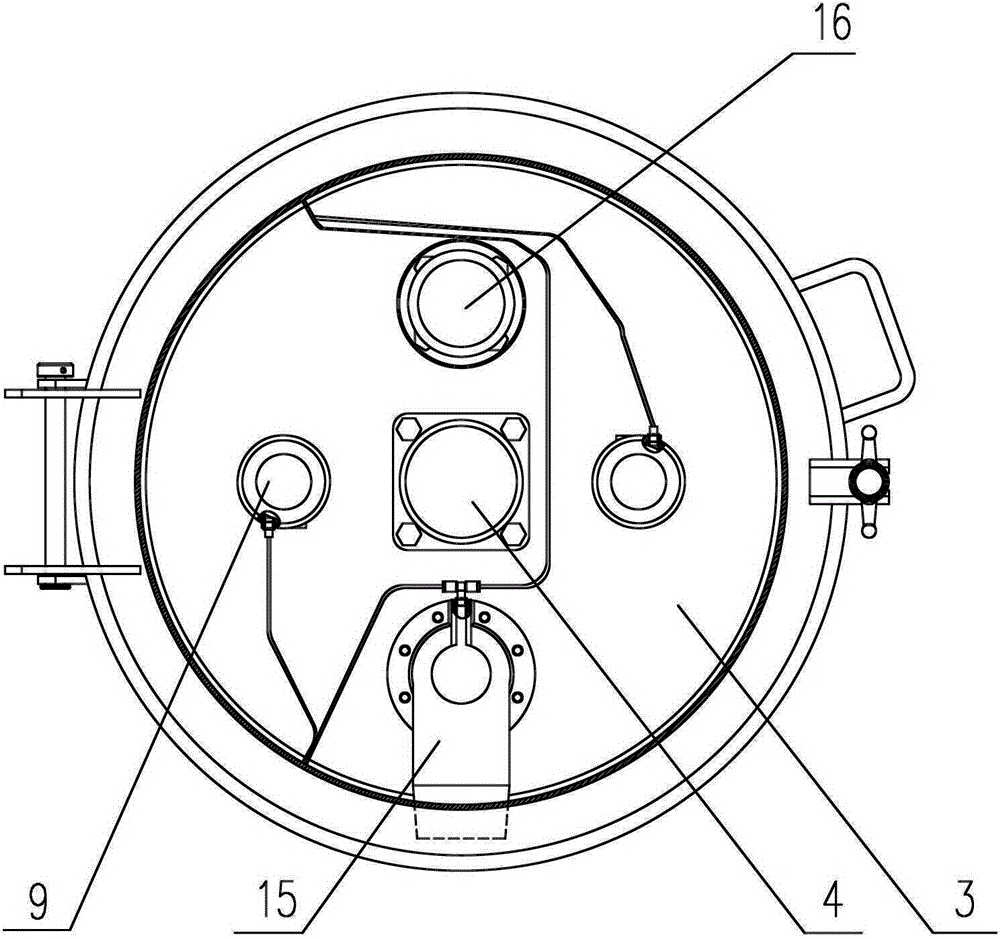

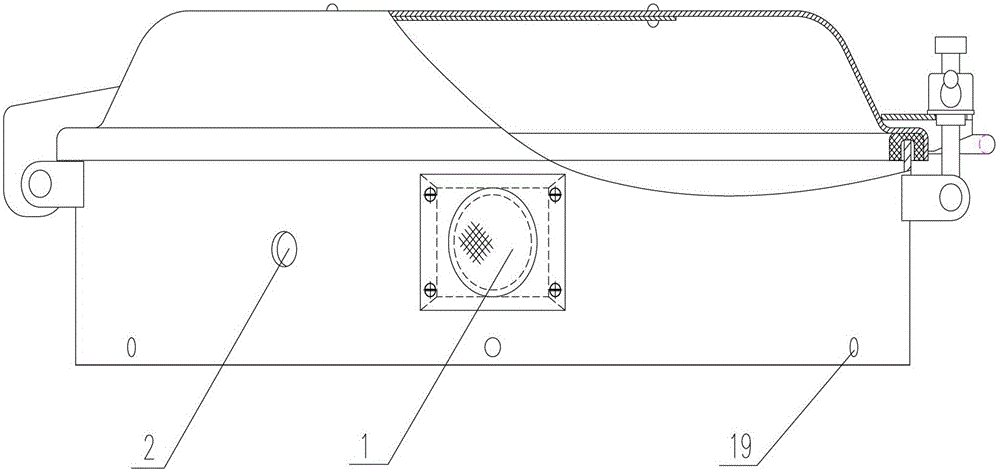

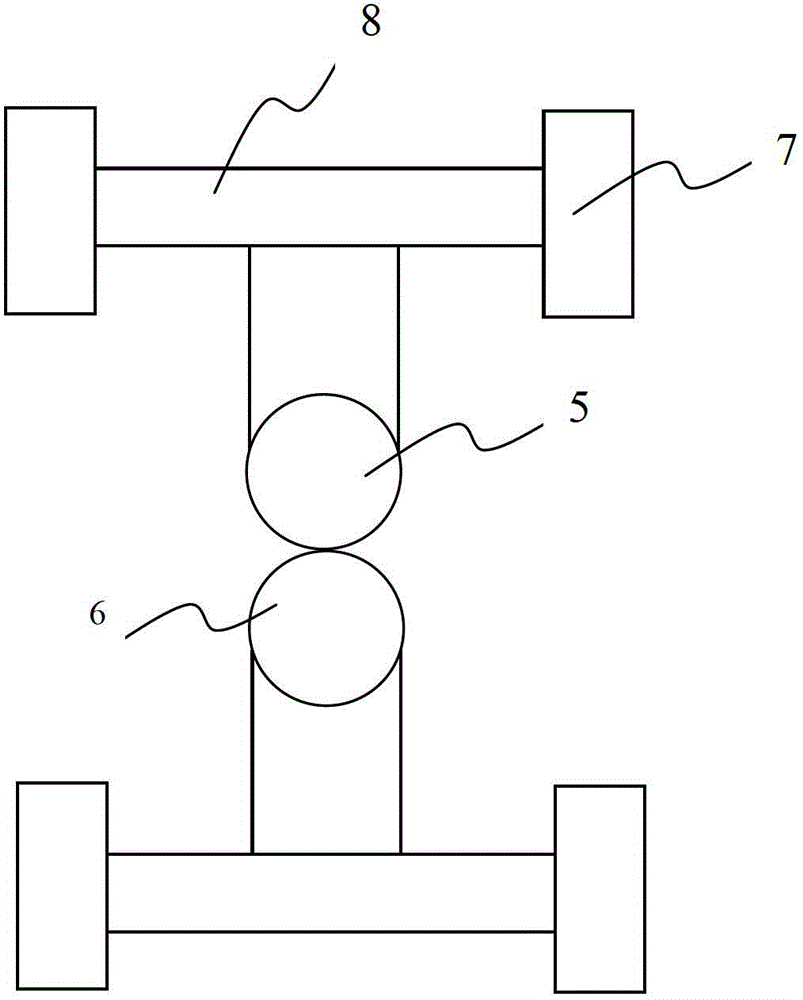

[0035] The invention provides a tank car filling and exhausting dynamic operation and remote monitoring system. The tank car filling and exhausting dynamic operation and remote monitoring system includes an oil filling and discharging valve seat and a filling and discharging device arranged at the bottom of the tank car from bottom to top, and a tank car The top overcharge automatic protection device, top valve group and valve group protective cover; the oil filling and discharging valve group is set at the bottom of the filling and discharging device; the overcharge automatic protection device is set on the top valve group; the valve group protective cover is connected to the top valve On the group; the overcharge automatic protection device transmits the signal to the ground controller through the socket, which is used for the shutdown of the ground control charging device. When the overcharge automatic protection device is adding medium to the tanker, when the medium reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com