Passive high-speed rotary die box

A technology of high-speed rotation and mold box, applied in the direction of wire drawing die, etc., can solve the problem that the bearing capacity of rolling bearing or sliding bearing cannot meet the requirements, achieve long service life, and save the effect of affecting production and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

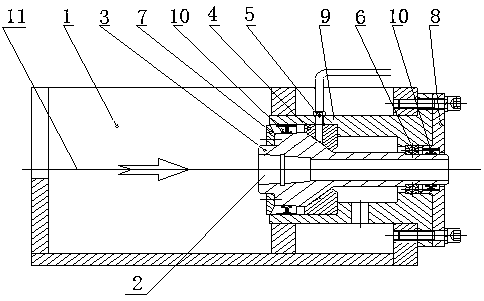

[0011] Such as figure 1 As shown, the present invention includes a rotating device installed in the box body 1, and the rotating device includes a screw mold 2, a hollow shaft 3, a tapered sliding bearing 4, an oil pipe 5 connected to a hydraulic station, and a second bearing 6 (central ball Bearings), front and rear covers 7, 8 and casing 9, the screw mold 2 is installed in the hollow shaft 3, the front part of the hollow shaft 3 is suspended in the tapered sliding bearing 4, and the oil pipe 5 passes through the tapered sliding bearing 4 and the hollow The shaft 3 contacts, the rear portion of the hollow shaft 3 is installed in the second bearing 6, the front cover 7 of the front end of the hollow shaft 3 is connected with the shell 9, and the back cover 8 of the rear end is connected with the shell 9 and the box body 1.

[0012] Oil seals 10 are respectively provided at the joints of the front cover 7 , the hollow shaft 3 , the shell 9 , and the tapered sliding bearing 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com