Process and apparatus for cooling a digestion vessel of a calorimeter after use

A technology of decomposer and calorimeter, which is applied in the field of decomposer devices, can solve the problems of high cost and long time of the devices, and achieve the effects of avoiding cooling, economical distribution and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

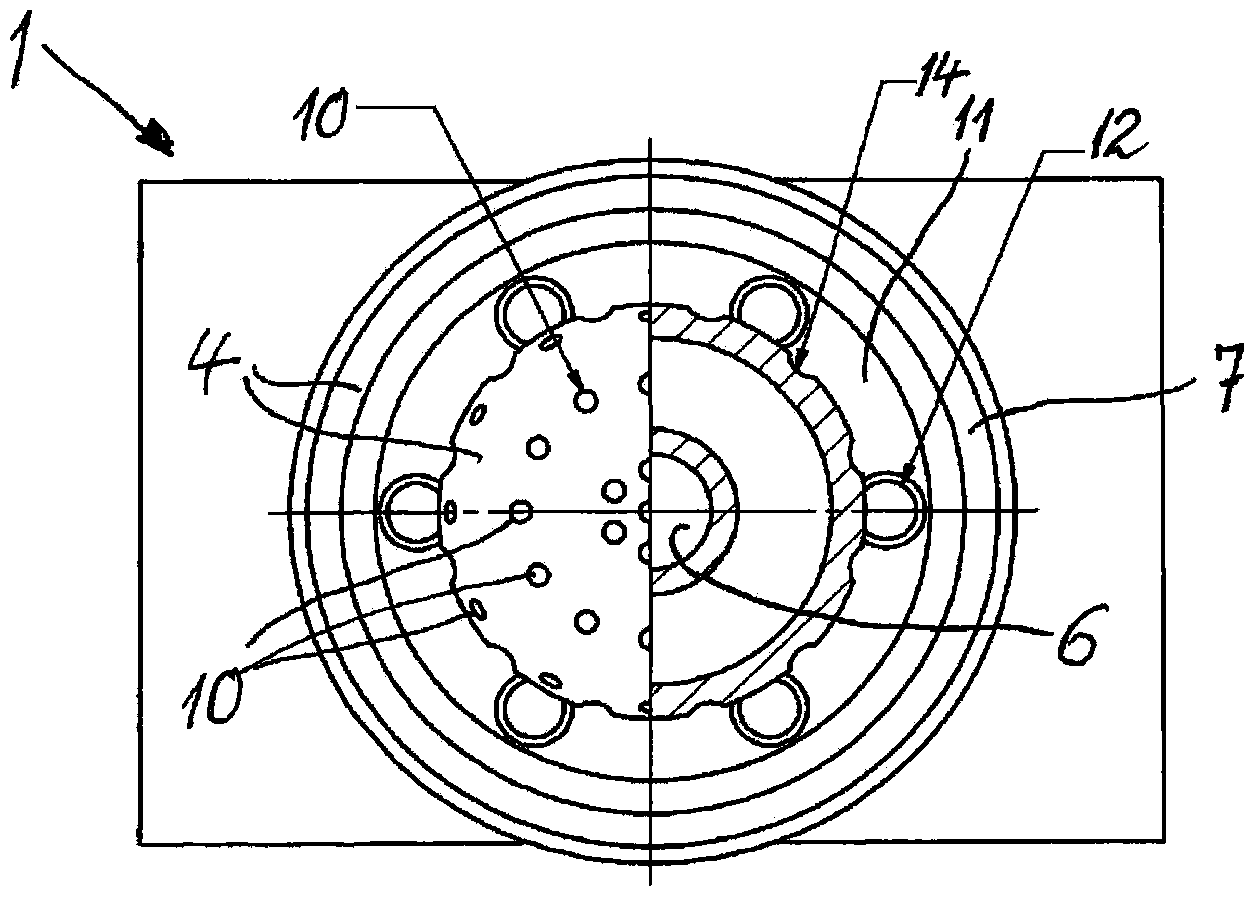

[0025] The device indicated as a whole by reference number 1 is used for cooling image 3 The decomposer 2 of the dry calorimeter 3 ( image 3 ). After use, such a decomposer 2 heats up considerably due to the combustion processes taking place therein, so it is particularly important that it can be returned to service as quickly as possible and that it can be recooled correspondingly quickly.

[0026] Device 1 also includes as figure 1 and figure 2 The bracket 4 shown, the bracket 4 is also defined as (in particular as image 3 The use position shown) accommodates the lower edge 5 of the resolver 2 or clamps the lower edge 5 of the resolver 2 during the cooling process.

[0027] Inside the bracket 4, people can image 3 Feed channels 6 for conveying coolant or cooling liquid, preferably water, are seen. This cooling liquid impinges on the upper surface of the support 4 and can thus wet the inner wall of the resolver 2 from the upper surface to cool it down.

[0028] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com