Hybrid drive assembly for motor vehicle

A technology of hybrid drive and automobile, which is applied in the direction of electric device, power device, air pressure power device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

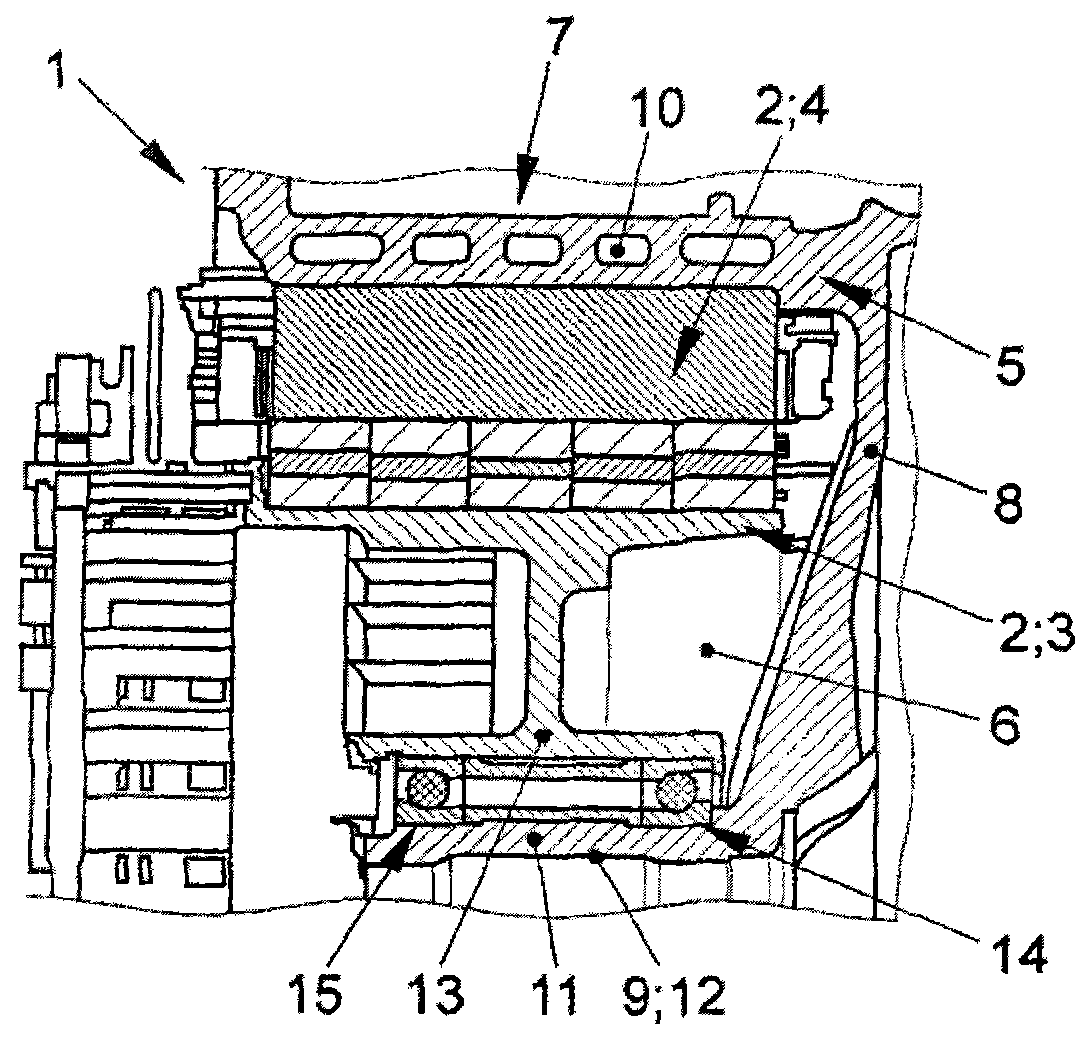

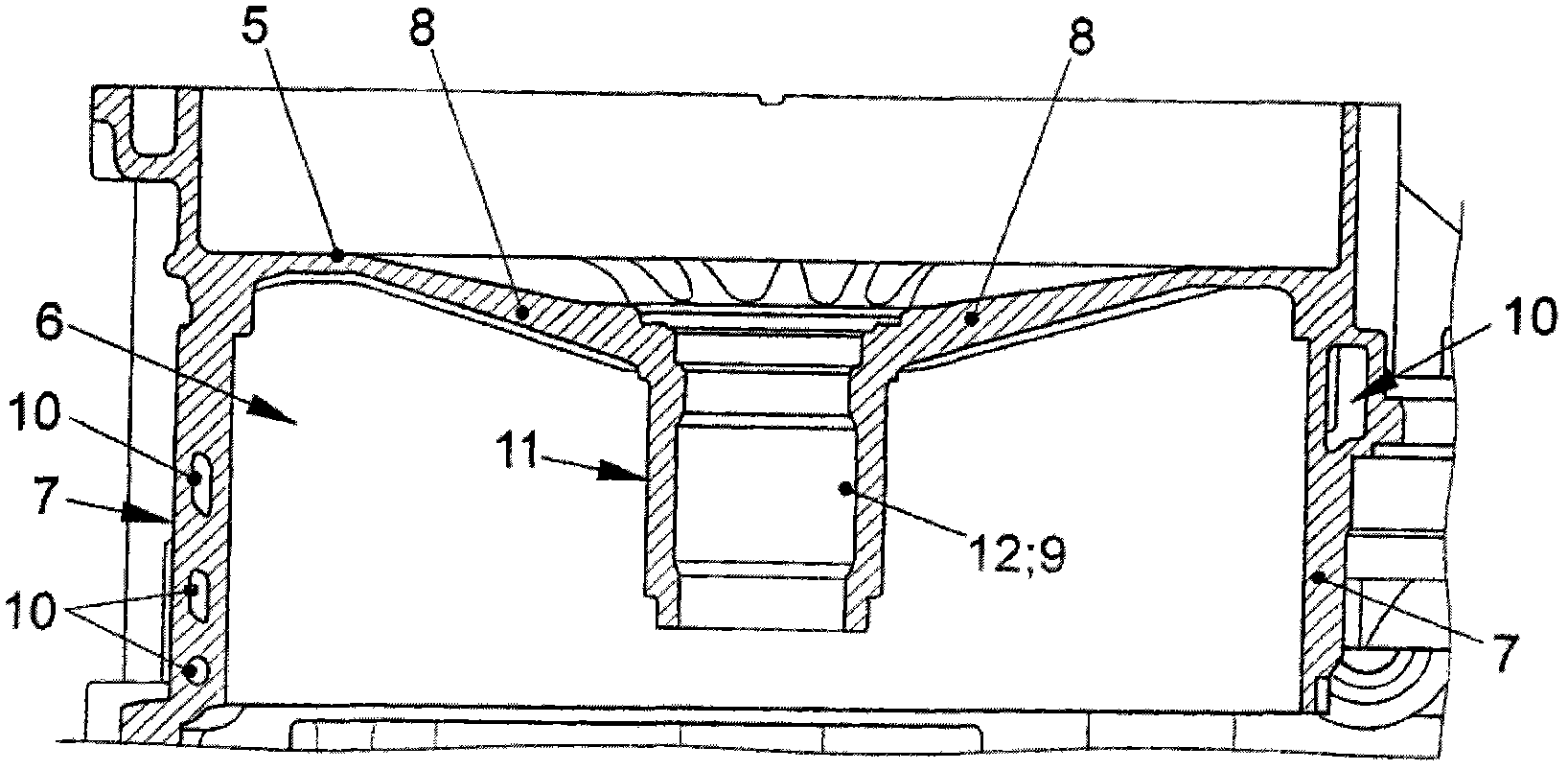

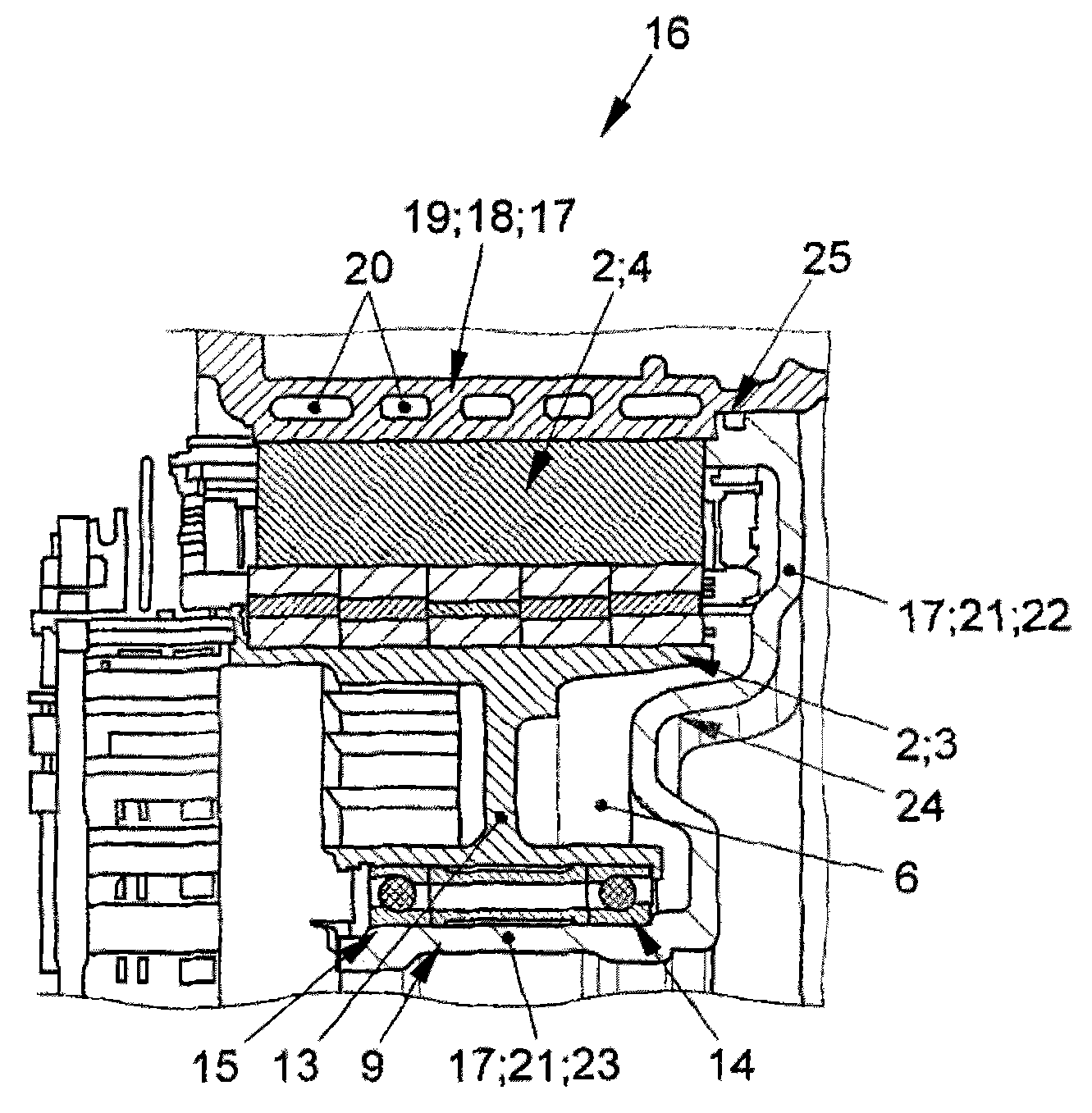

[0013] exist figure 1 The hybrid drive 1 is clearly visible in . The hybrid drive 1 is part of a drive train of a motor vehicle. The hybrid drive 1 includes an electric machine 2 with a rotor 3 and a stator 4 . The rotor 3 and the stator 4 are arranged in a housing 5 . In addition, a shaft (not shown in the figure) is provided. In particular, the shaft can be driven by the internal combustion engine. The shaft can be designed as a clutch input shaft. The housing 5 is designed in particular as a clutch housing.

[0014] The housing 5 defines an oil chamber 6 . The oil chamber 6 is open from the transmission side and is filled accordingly. The rotor 3 and the stator 4 are arranged in an oil chamber 6 . The housing 5 has a housing region 7 and side walls 8 . The jacket region 7 extends substantially axially and circumferentially. The side walls 8 extend inwardly from the cover region 7 . Firstly, the side walls 8 extend substantially radially inwards from the housing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com