Gas pipeline automatic controller

An automatic controller and gas pipeline technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of increasing the workload of the staff and reducing the work efficiency of the staff, and achieve the improvement of work efficiency and the level of automation, sealing The structure is safe and reliable, and the maintenance is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0021] Such as figure 1 , Figure 2, image 3 Shown:

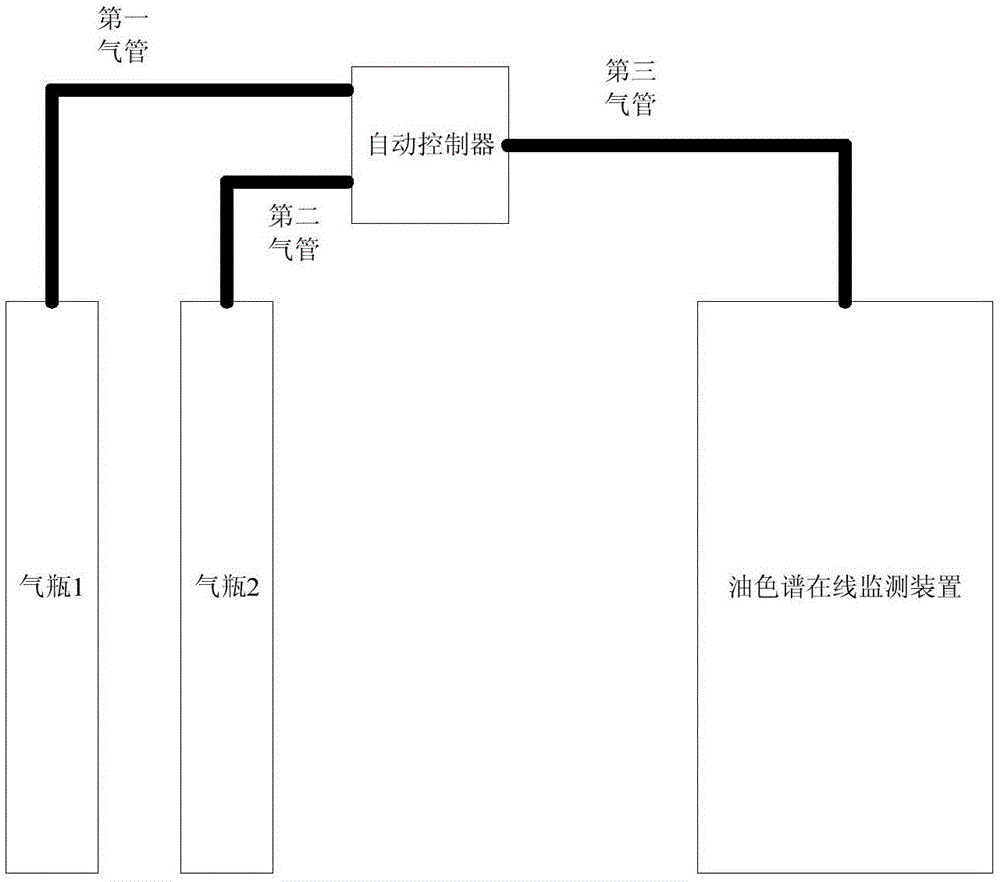

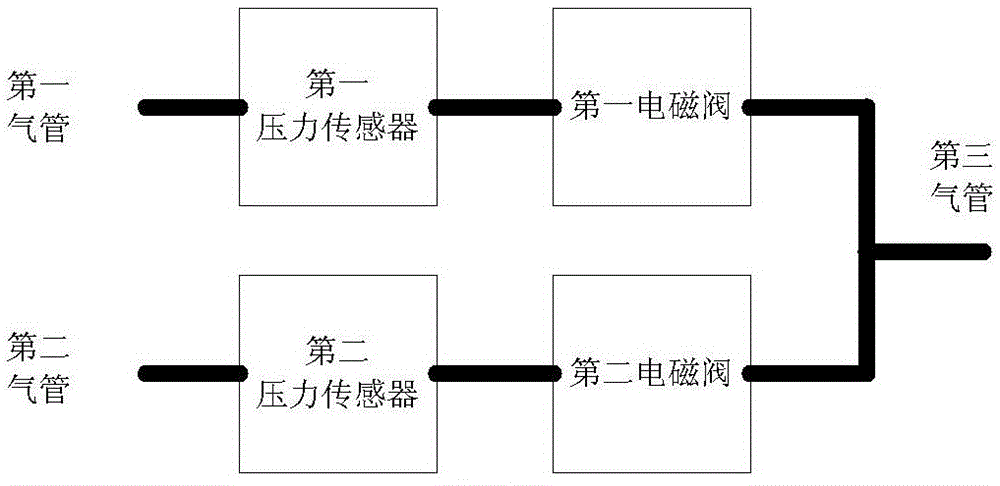

[0022] The gas pipeline automatic controller is installed between gas cylinder 1, gas cylinder 2 and the oil chromatography on-line monitoring device, and plays the role of automatically switching the two gas cylinders. Gas cylinder 1 and gas cylinder 2 are respectively connected to the automatic controller through the first air pipe and the second air pipe, specifically as figure 2 Shown:

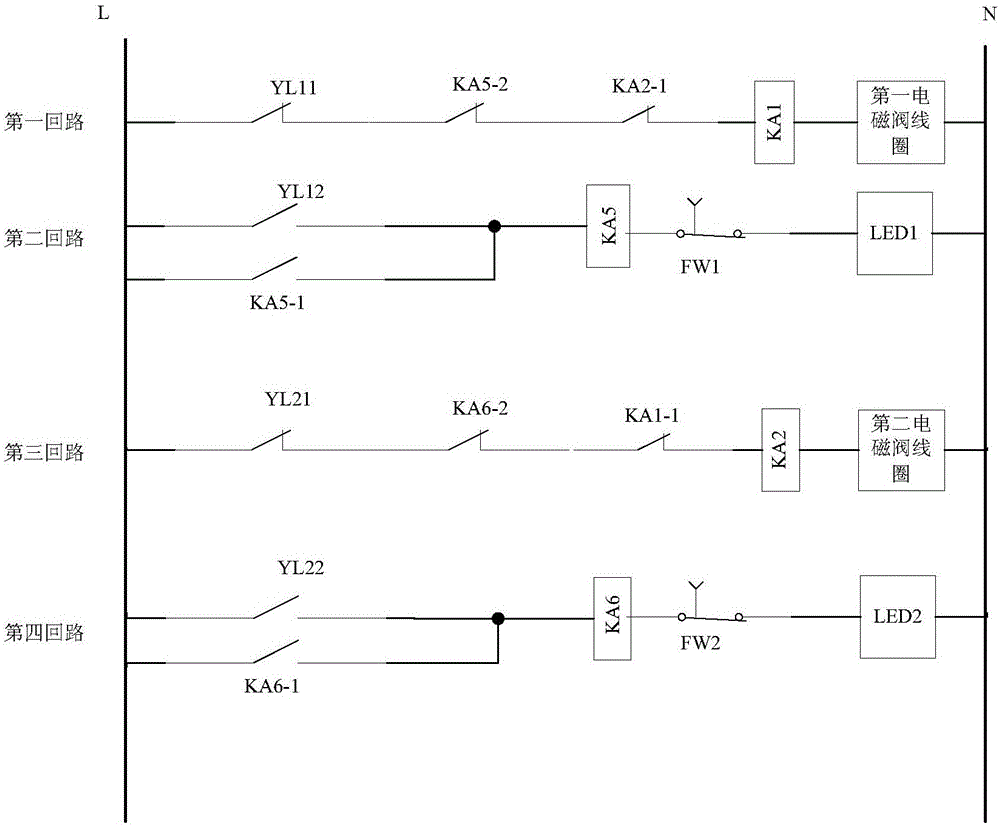

[0023] The gas pipeline automatic controller includes a first pressure sensor, a second pressure sensor, a first electromagnetic valve, a second electromagnetic valve and a control circuit.

[0024] A first pressure detector is installed on the first air pipe, and a first electromagnetic valve is also arranged on the first air pipe behind the first pressure detector; a second pressure detector is installed on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com