A control method suitable for barley drying equipment

A control method and drying equipment technology, applied in the field of beer malt material preparation and storage technology, can solve the problems that there is no clear start-up process for the equipment operation sequence of the drying tower system, the inability to save time and energy consumption, and the inability to carry out malt fermentation, etc., to achieve Reduces barley raw material loss, saves time and energy consumption, controls simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

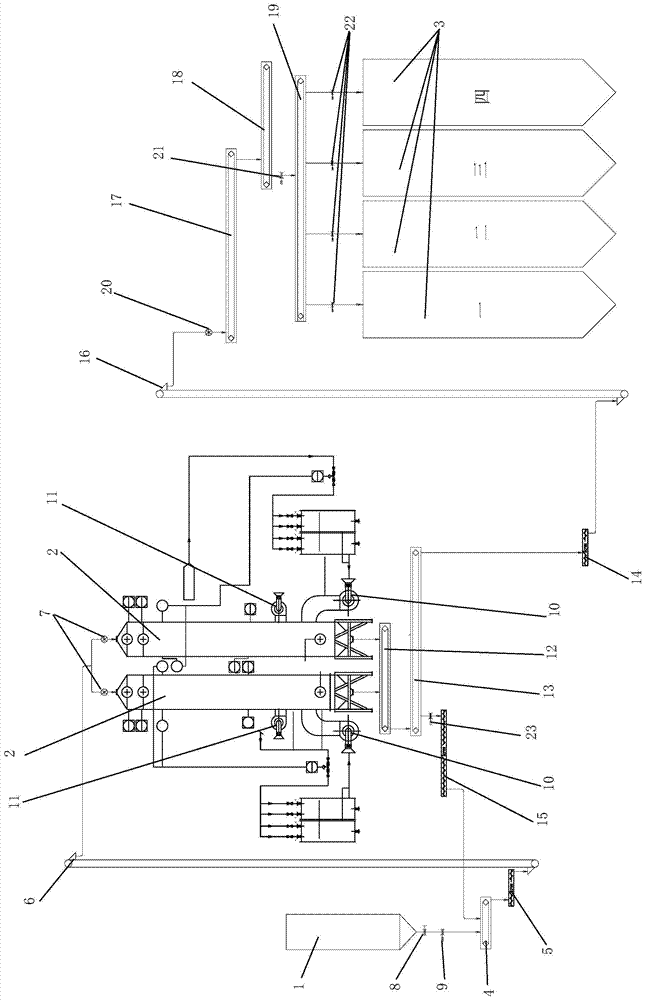

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The invention provides a control method suitable for barley drying equipment, such as figure 1 As shown, the drying equipment includes a pre-drying warehouse 1, two drying towers 2 and several barley silos 3.

[0028] Between the pre-drying warehouse 1 and the drying tower 2, a first scraper conveyor 4, a first sealing screw conveyor 5, and a first bucket elevator 6 are arranged in sequence. The first bucket elevator 6 is respectively connected to the two drying towers 2 through a feeding pipeline, and the feeding pipelines at the top of the drying towers 2 are each provided with a first star feeder 7 . A manual slide valve 8 and a first pneumatic slide valve 9 are provided between the pre-drying bin 1 and the first scraper conveyor 4 .

[0029] The main body of each drying tower 2 is provided with a drying main fan 10 and a cooling fan 11 , and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com