A constant force output air flotation device with guide rail following

A technology of constant force output and air flotation, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. Insufficient precision and other problems, to achieve the effect of no tracheal disturbance, high precision of constant force output, and good carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

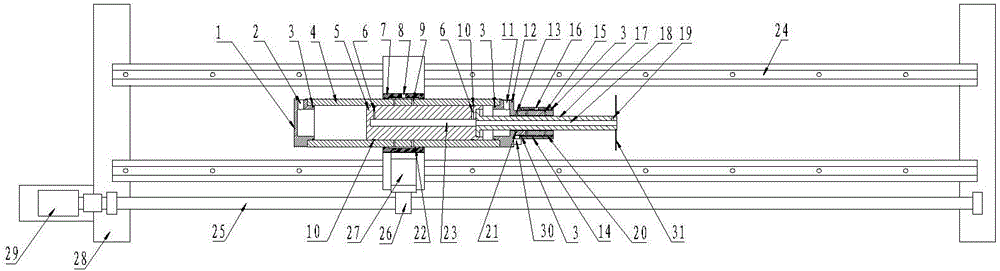

[0029] combine figure 1 , a constant force output air flotation device with guide rail following, including an output cylinder and a follower device; the follower device includes a slider, two linear guide rails 24, a motor 29, and a ball screw 25; the slider has two and is respectively sleeved on On the linear guide 24 , both ends of the linear guide 24 are supported by the support 28 , and the motor 29 is mounted on the support 28 and connected to the ball screw 25 .

[0030] The output cylinder includes a piston 5, a piston rod 17, a cylinder barrel 4, an end cover 1, a cylinder barrel cover 12, and an air intake sleeve. A connecting plate 27 is installed under the cylinder barrel 4, and the connecting plate 27 is fixedly connected with the two sliders. The lead screw 25 is connected to the connecting plate 27 through the nut seat 26 .

[0031] The piston 5 is sheathed in the cylinder barrel 4 and there is a very small gap between it and the wall of the cylinder barrel. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com