High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, polyvinyl chloride technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance and aging resistance, narrow temperature range, low mechanical properties of cables, etc., and achieves high temperature resistance. The effect of adapting to a wide temperature range and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

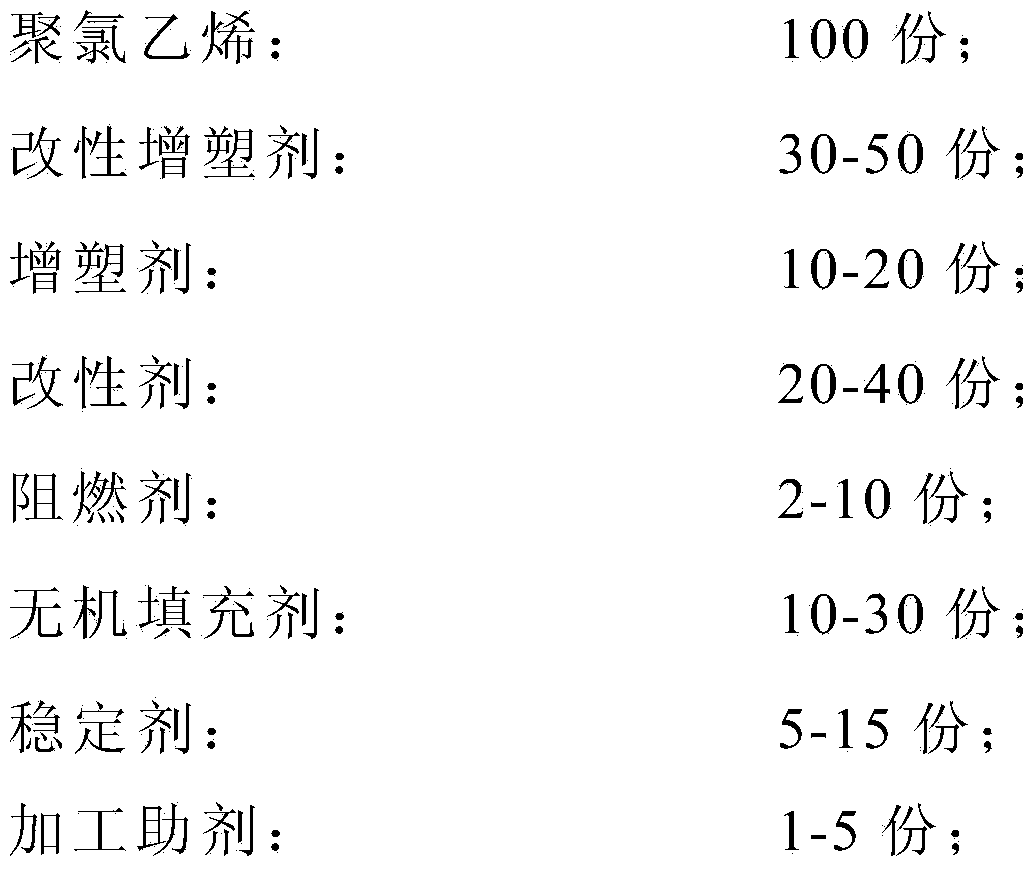

Method used

Image

Examples

Embodiment 1

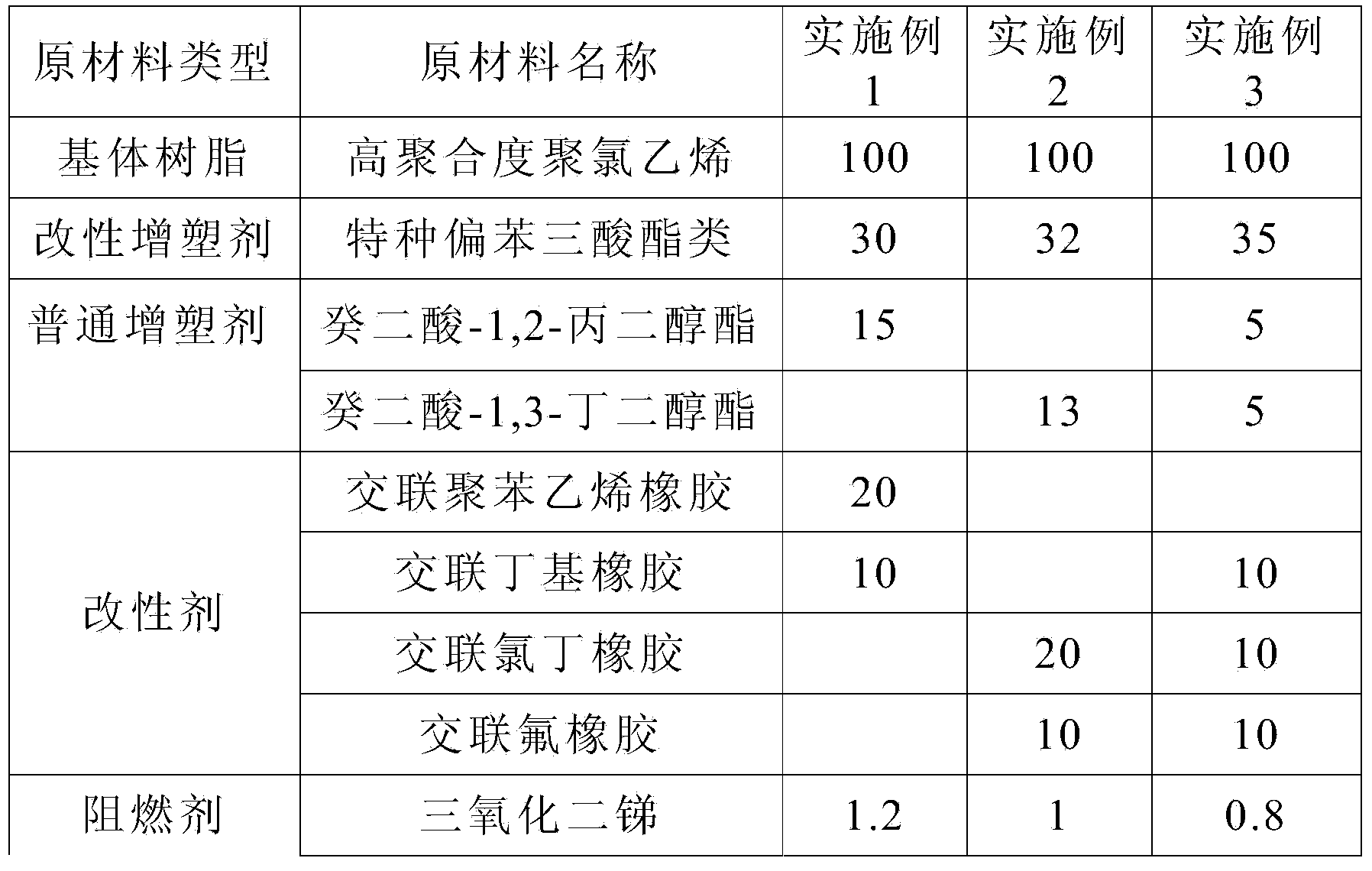

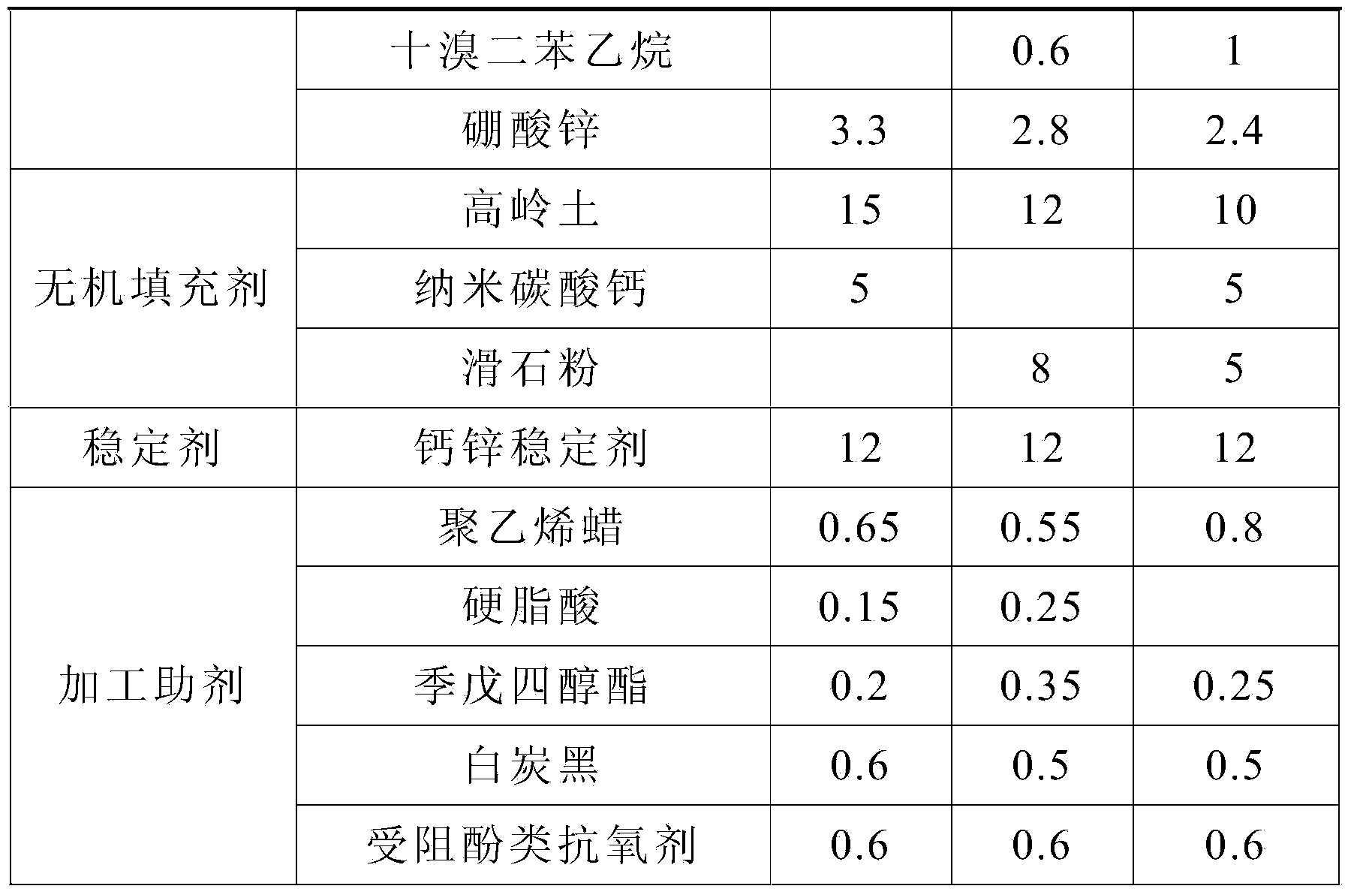

[0035] Various raw materials were weighed according to the composition and parts by weight of the high-temperature-resistant thermoplastic polyvinyl chloride cable material described in Example 1 in Table 1;

[0036] Pour the above weighed polyvinyl chloride into a high-mixer and mix. After mixing evenly, add the weighed modified plasticizer and ordinary plasticizer, and stir until the modified plasticizer, ordinary plasticizer is heated to 100°C. After the plasticizer is completely absorbed by the polyvinyl chloride, add the weighed modifier, flame retardant, inorganic filler, stabilizer and processing aid, and stir until the raw materials are completely uniform;

[0037] The above-mentioned uniformly stirred raw materials are discharged from the high mixer, poured into the feeder, and fed into the twin-screw extruder by the feeder to extrude and granulate. The feeding frequency of the feeder is 25Hz, and the twin-screw extruder The temperature of the extruder was set at 180°...

Embodiment 2

[0039] Various raw materials were weighed according to the composition and parts by weight of the high-temperature-resistant thermoplastic polyvinyl chloride cable material described in Example 2 in Table 1;

[0040] Pour the above weighed polyvinyl chloride into a high-mixer and mix it. After mixing evenly, add the weighed modified plasticizer and ordinary plasticizer. When heated to 90°C, stir until the modified plasticizer, ordinary plasticizer After the plasticizer is completely absorbed by the polyvinyl chloride, add the weighed modifier, flame retardant, inorganic filler, stabilizer and processing aid, and stir until the raw materials are completely uniform;

[0041] The above-mentioned uniformly stirred raw materials are discharged from the high mixer, poured into the feeder, and fed into the twin-screw extruder by the feeder to extrude and granulate. The feeding frequency of the feeder is 20Hz, and the twin-screw extruder The temperature of the extruder was set at 170°...

Embodiment 3

[0043] According to the composition and parts by weight of the high-temperature-resistant thermoplastic polyvinyl chloride cable material described in Example 3 in Table 1, various raw materials are weighed;

[0044] Pour the above weighed polyvinyl chloride into a high-mixer and mix. After mixing evenly, add the weighed modified plasticizer and ordinary plasticizer. When heated to 110°C, stir until the modified plasticizer, ordinary plasticizer After the plasticizer is completely absorbed by the polyvinyl chloride, add the weighed modifier, flame retardant, inorganic filler, stabilizer and processing aid, and stir until the raw materials are completely uniform;

[0045] The above-mentioned uniformly stirred raw materials are discharged from the high mixer, poured into the feeder, and fed into the twin-screw extruder by the feeder to extrude and granulate. The feeding frequency of the feeder is 30Hz, and the twin-screw extruder The temperature of the extruder was set at 190° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com