Antioxidative peptide of shark protein as well as preparation method and use thereof

An antioxidant peptide, shark technology, applied in the field of shark protein antioxidant peptides, can solve the problems of high activity antioxidant peptides that have not been reported, and achieve the effects of no toxic side effects, scientific and reasonable process, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]1) Put the cleaned, boned and skinned scalloped hammerhead shark meat into a buffer solution with a solid-to-liquid ratio of 1g:1mL, such as phosphate buffer as a pH regulator, and use a high-speed tissue masher to process it into Homogenize, then degrease in ether for 24 hours according to volume ratio 1:4, centrifuge at 4°C, 4500rpm for 15 minutes to remove ether, and collect solids;

[0038] 2) Add the defatted fish meat to a buffer solution according to the solid-to-liquid ratio of 1g:20mL, such as phosphate buffer, and adjust the pH to 6.0 with 0.05~0.15mol / L HCl or 0.05~0.15mol / L NaOH to obtain a mixture;

[0039] 3) Raise the temperature of the mixture to 55°C, stir and preheat for 10 minutes, add papain according to 1.2% of the mass of defatted fish meat, enzymolysis temperature is 60°C, and enzymolysis time is 2 hours, to obtain the enzymolysis product;

[0040] 4) The enzymatic hydrolyzate obtained in step 3) is first treated with enzyme inactivation to obtain ...

Embodiment 2

[0049] 1) Put the washed, boned and skinned Hammerhead Shark meat into the buffer according to the solid-liquid ratio of 1g:2mL, process it into a homogenate with a high-speed tissue masher, and then according to the volume ratio of 1:2 Degrease in ether for 20 hours, centrifuge at 4°C, 5000 rpm for 10 minutes to remove ether, and collect solids;

[0050] 2) Add the defatted fish meat to the buffer according to the solid-to-liquid ratio of 1g:15mL, and adjust the pH to 6.0 with 0.1mol / L HCl or 0.1mol / L NaOH to obtain a mixture;

[0051] 3) Raise the temperature of the mixture to 50°C, stir and preheat for 10 minutes, add papain according to 1.0% of the mass of defatted fish meat, enzymolysis temperature is 50°C, and enzymolysis time is 3 hours, to obtain the enzymatic hydrolysis product.

[0052] Next step is with embodiment 1.

Embodiment 3

[0054] 1) Put the cleaned, boned and skinned scalloped hammerhead shark meat into the buffer at a solid-to-liquid ratio of 1g:1.5mL, process it into a homogenate with a high-speed tissue grinder, and then use a volume ratio of 1: 3 Degrease in ether for 22 hours, centrifuge at 4°C, 4000rpm for 13 minutes to remove ether, and collect solids;

[0055] 2) Add the defatted fish meat to the buffer according to the solid-to-liquid ratio of 1g:17mL, and adjust the pH to 6.0 with 0.1mol / L HCl or 0.1mol / L NaOH to obtain a mixture;

[0056] 3) Raise the temperature of the mixture to 55°C, stir and preheat for 8 minutes, add papain according to 0.8% of the mass of defatted fish meat, enzymolysis temperature is 55°C, and enzymolysis time is 2 hours, to obtain the enzymolysis product.

[0057] Next step is with embodiment 1.

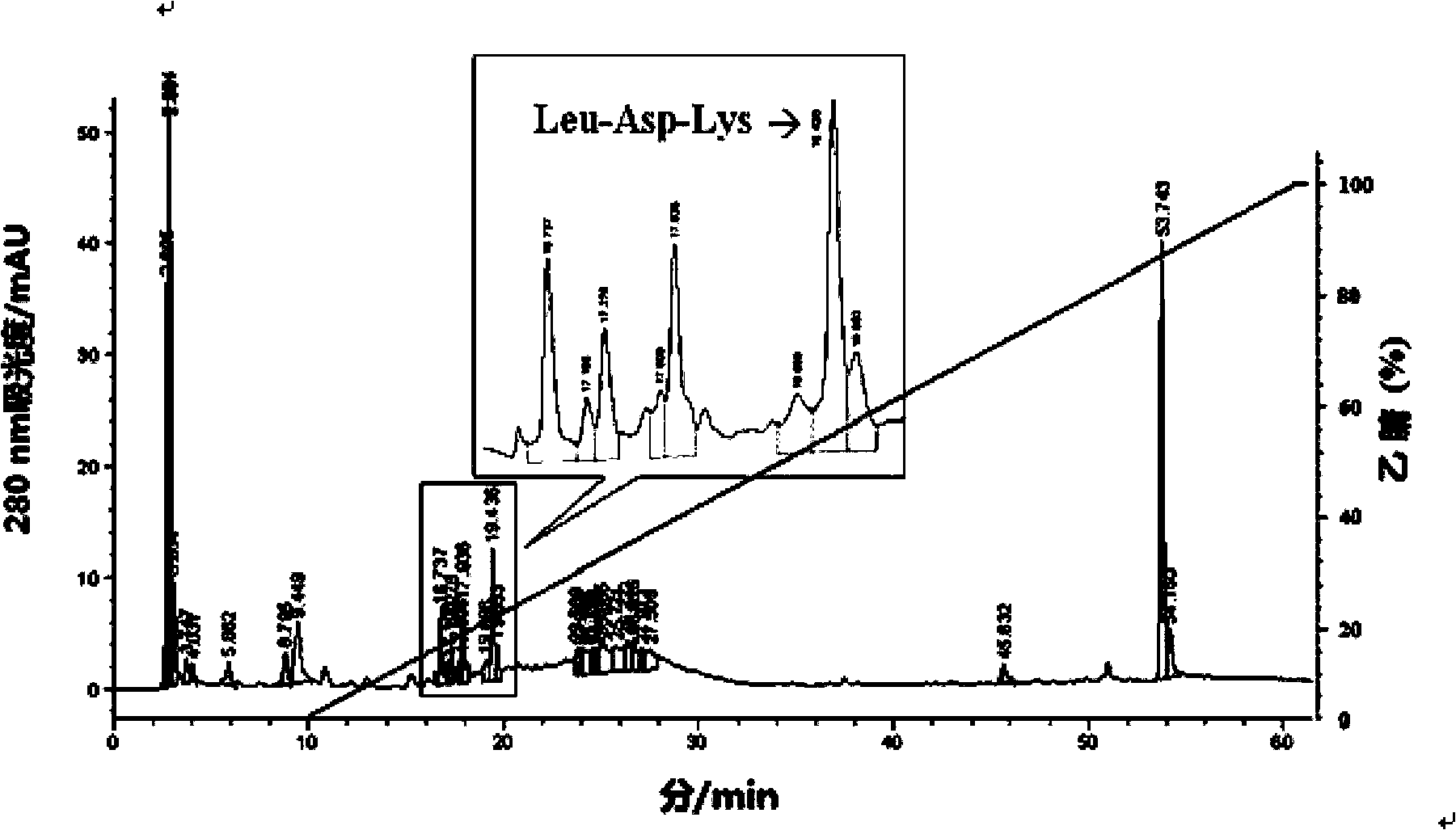

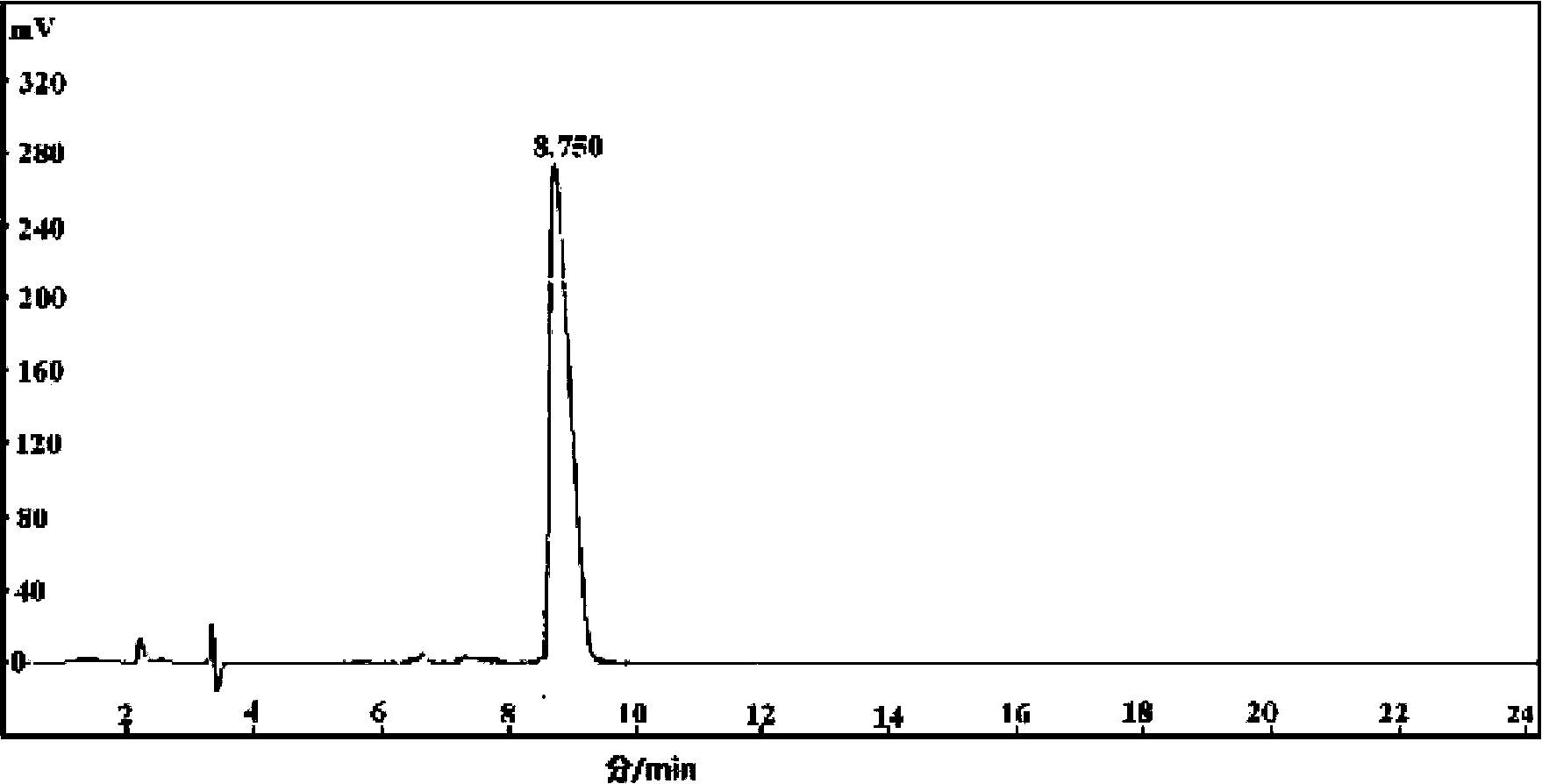

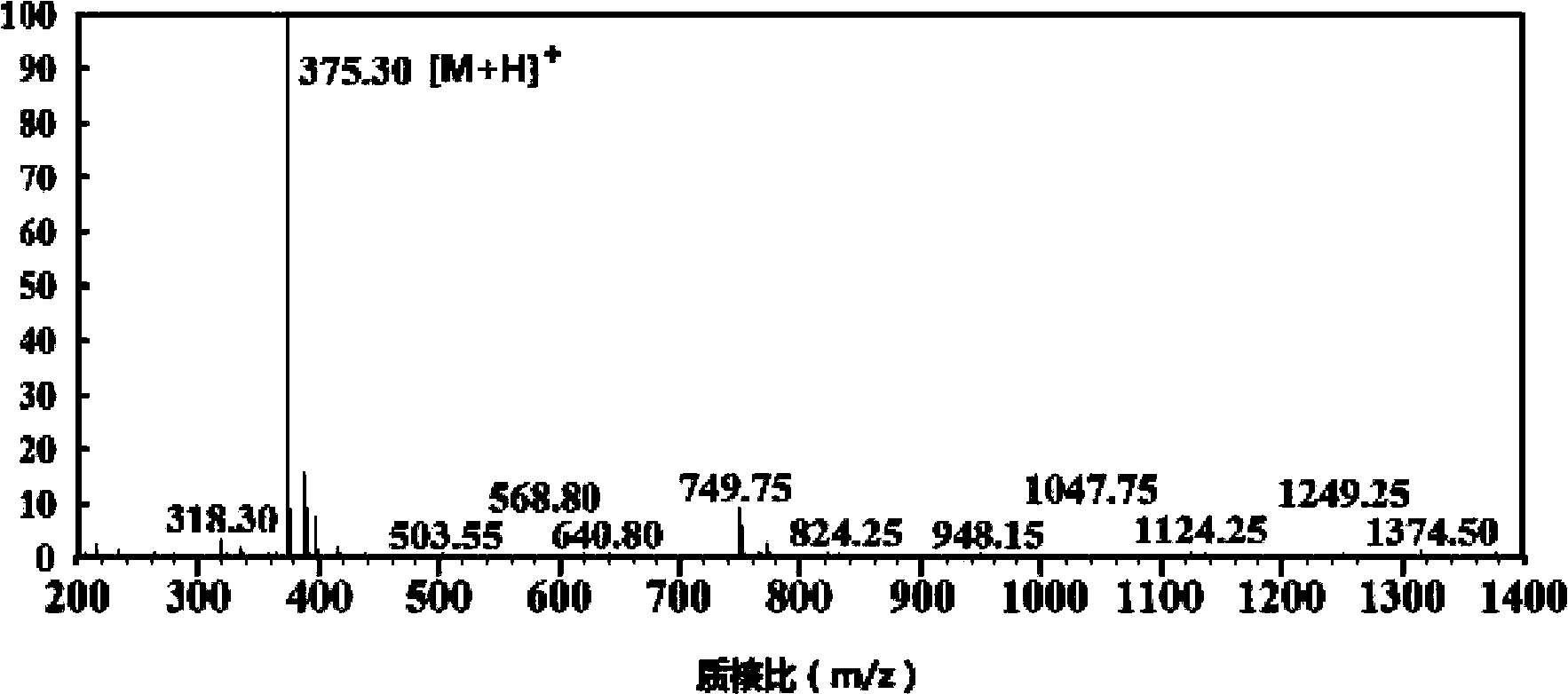

[0058] Carry out DPPH free radical scavenging experiment (see Figure 4 ), hydroxyl radical scavenging experiment (see Figure 5 ), ABTS free radical scavenging e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com