Full-automatic rotary u-turn machine

A rotary U-turn machine, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem that rectangular tiles cannot be rotated and turned, sprayed or printed, etc., to achieve simple structure, stable process, and increase the stress area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

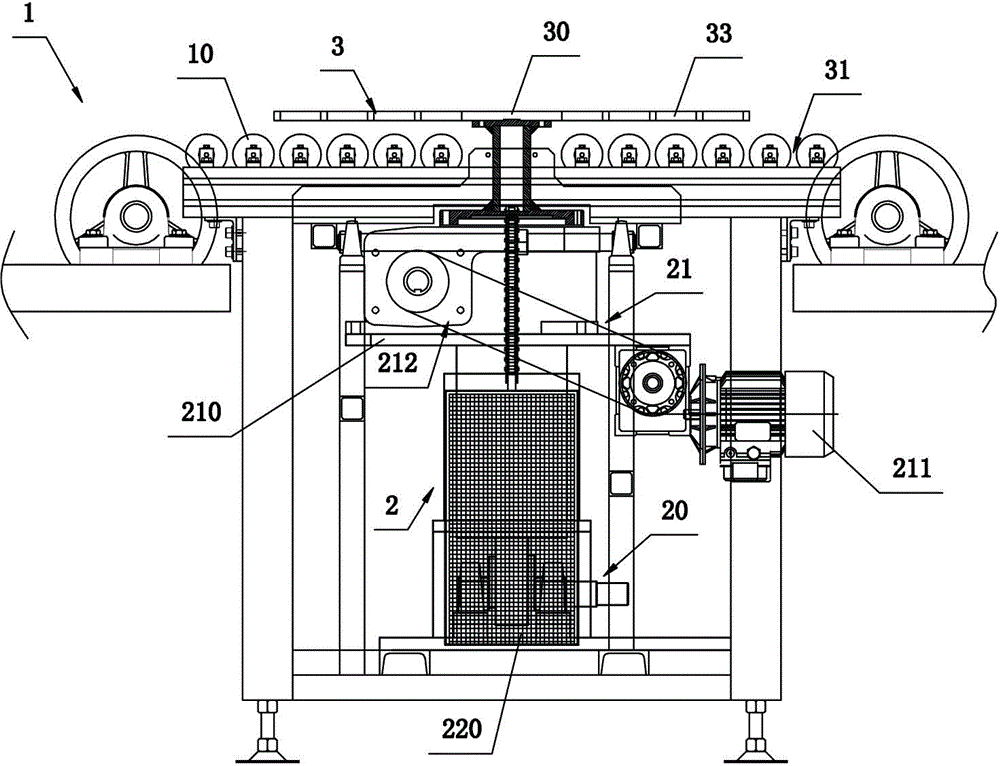

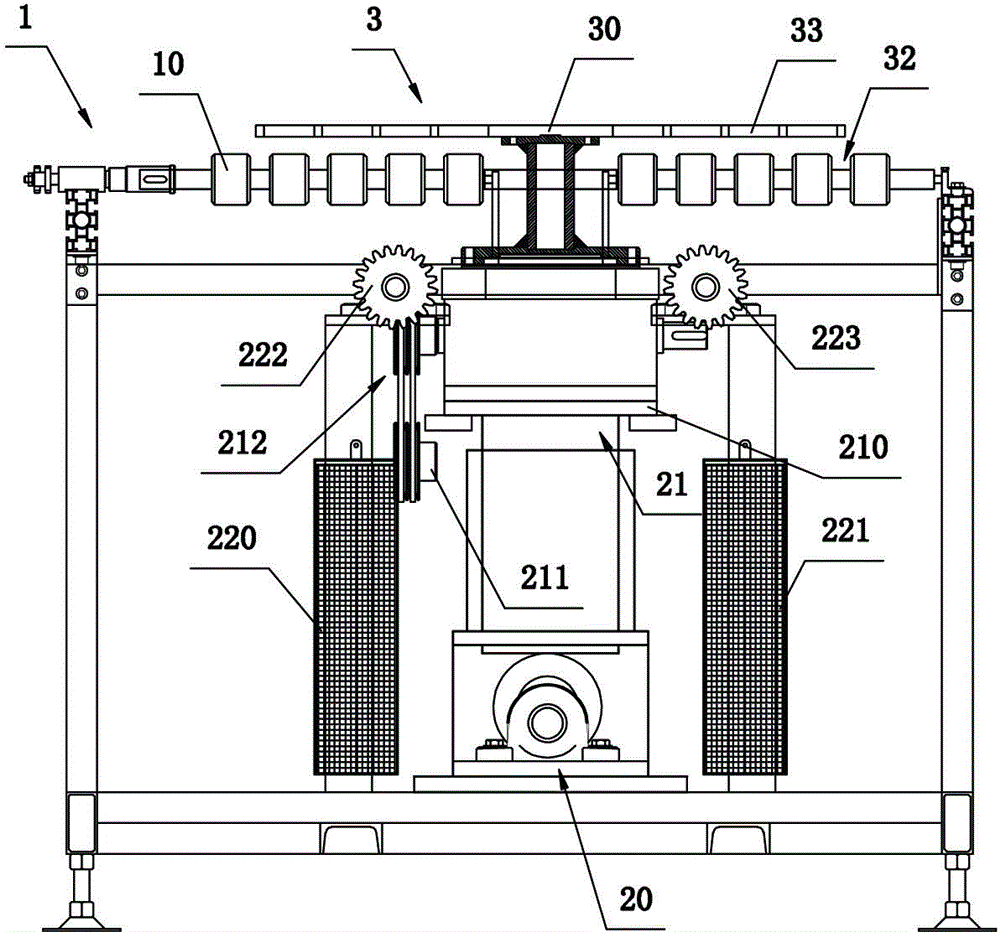

[0024] refer to figure 1 and figure 2 . A fully automatic rotary U-turn machine, comprising a stick transmission mechanism 1, a rotating lifting mechanism 2 located below the stick transmission mechanism 1 and a lifting frame 3, the stick sleeve on the stick transmission mechanism 1 is provided with a stick tube, and the stick The barrel is provided with a plurality of segment-shaped stick barrels 10, and each segment-shaped stick barrel 10 is arranged at intervals along the length direction of the stick. The holding frame 3 is a grid-like holding frame formed by the vertical crossing of a plurality of horizontal frame plates and longitudinal frame plates. Compatible with grid 33. The grids 33 on the lifting frame 3 have the same size, and the areas occupied by the segmented sticks 10 are consistent, the transverse frame plates are located in the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com