Regulating and controlling device of gas-liquid booster-type die-cutting machine

A gas-liquid pressurization and control device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high cost, complex system structure, difficult processing and assembly, etc., and achieve simple processing and assembly, good control effect, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

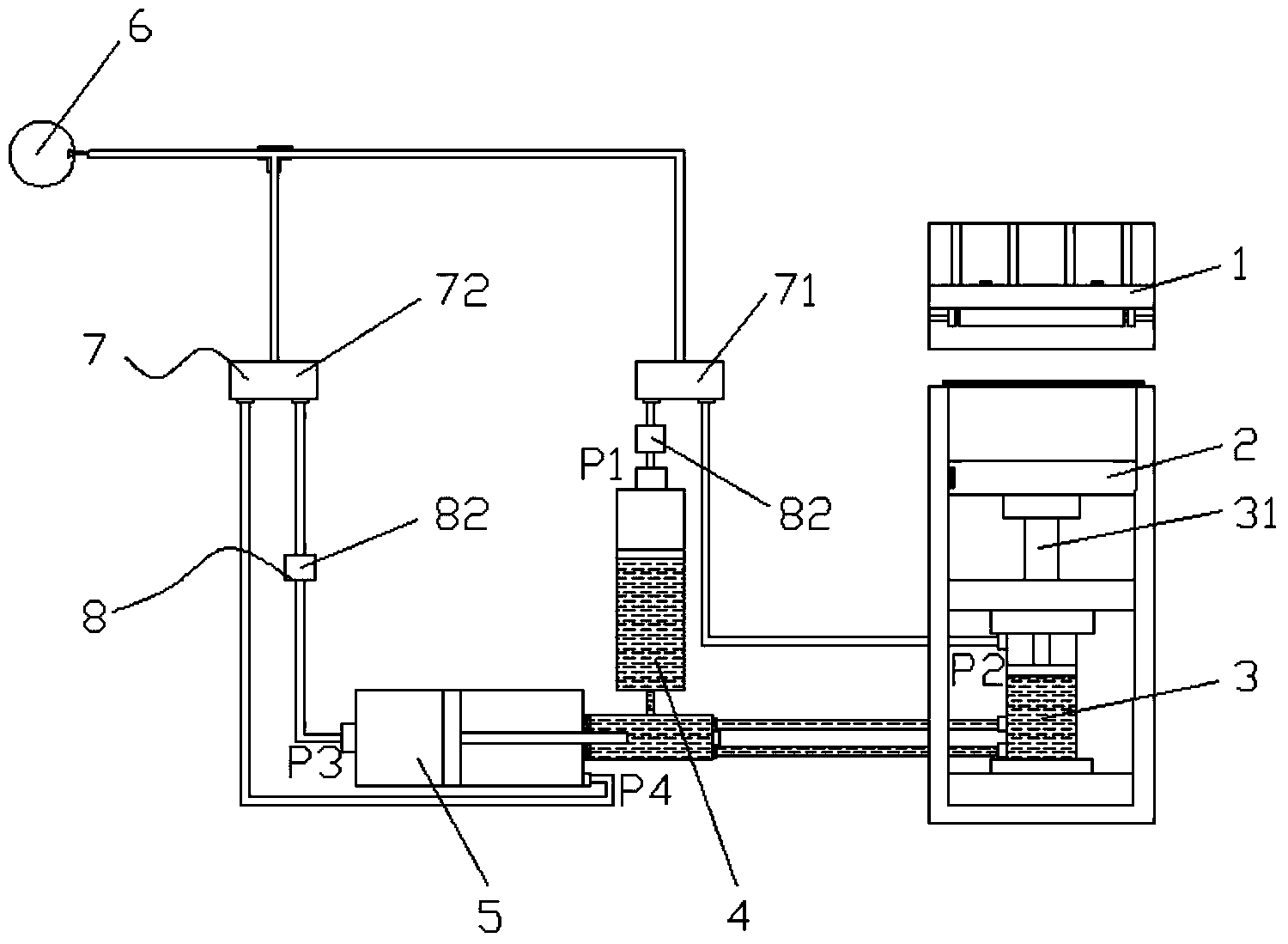

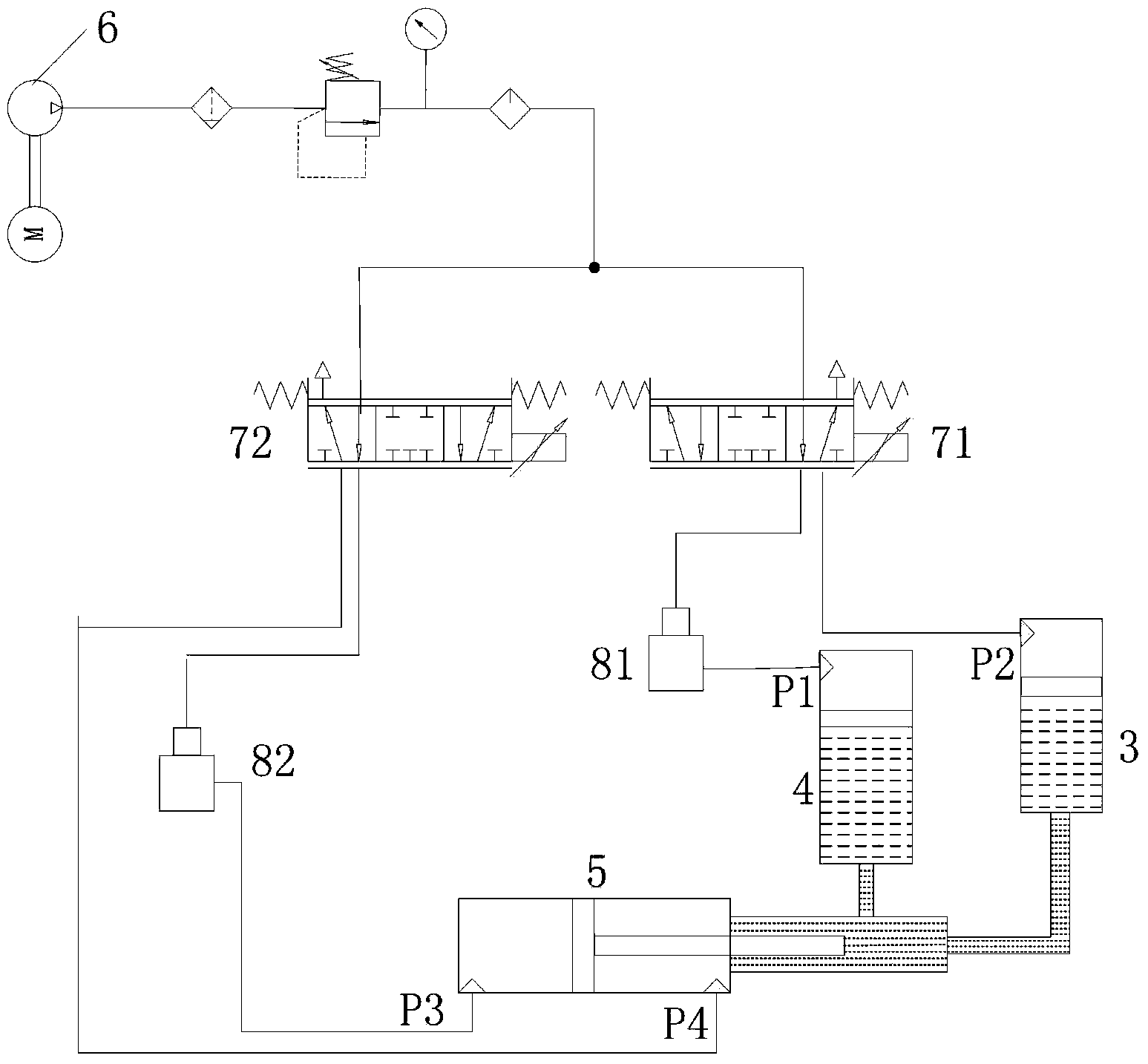

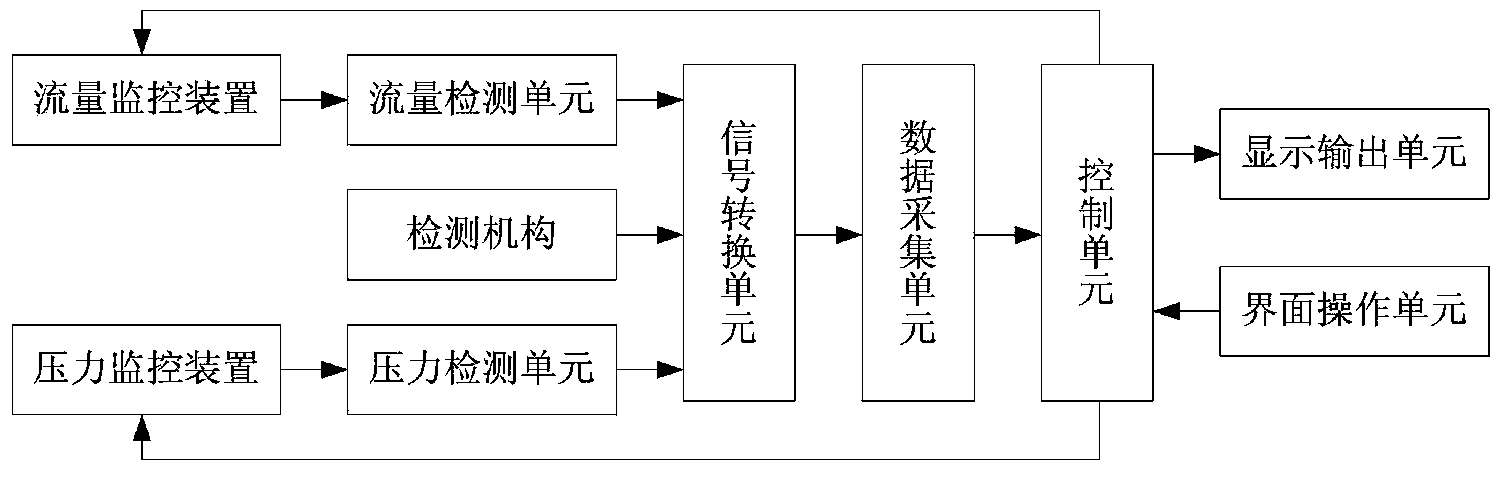

[0024] A gas-liquid pressurized die-cutting machine regulating device of the present invention comprises: a gas-liquid pressurized die-cutting machine; a flow regulating device installed between the gas-liquid pressurized die-cutting machine and a gas source for Real-time adjustment of the intake flow rate of the gas-liquid booster die-cutting machine; a flow detection unit for real-time detection of the intake flow rate of the gas-liquid booster die-cutting machine; installed between the flow adjustment device and the gas-liquid booster The pressure regulating device between the die-cutting machines is used to adjust the intake pressure of the gas-liquid booster die-cutting machine in real time; the pressure detection unit for real-time detection of the intake pressure of the gas-liquid booster die-cutting machine ; control device.

[0025] Wherein, the control device receives the real-time intake flow of the gas-liquid pressurized die-cutting machine output by the flow detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com