Needle feeding and head assembling mechanism of acupuncture needle automatic handle winding machine

A handle-winding machine and acupuncture needle technology, which is applied in the field of needle-feeding and head-loading mechanism of automatic needle-winding machine, can solve the problems that the needle-feeding and head-loading mechanism has not been described in detail, and achieve smooth and high-speed working process, flexible action, relatively Well-placed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

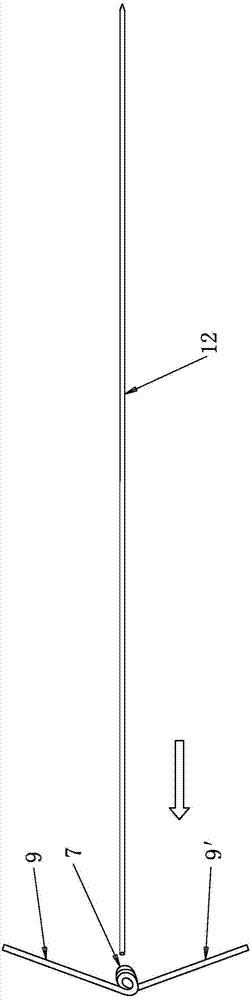

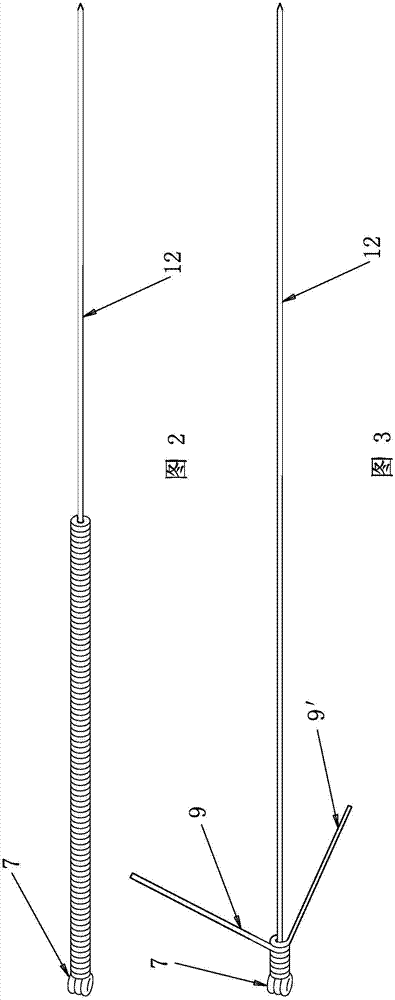

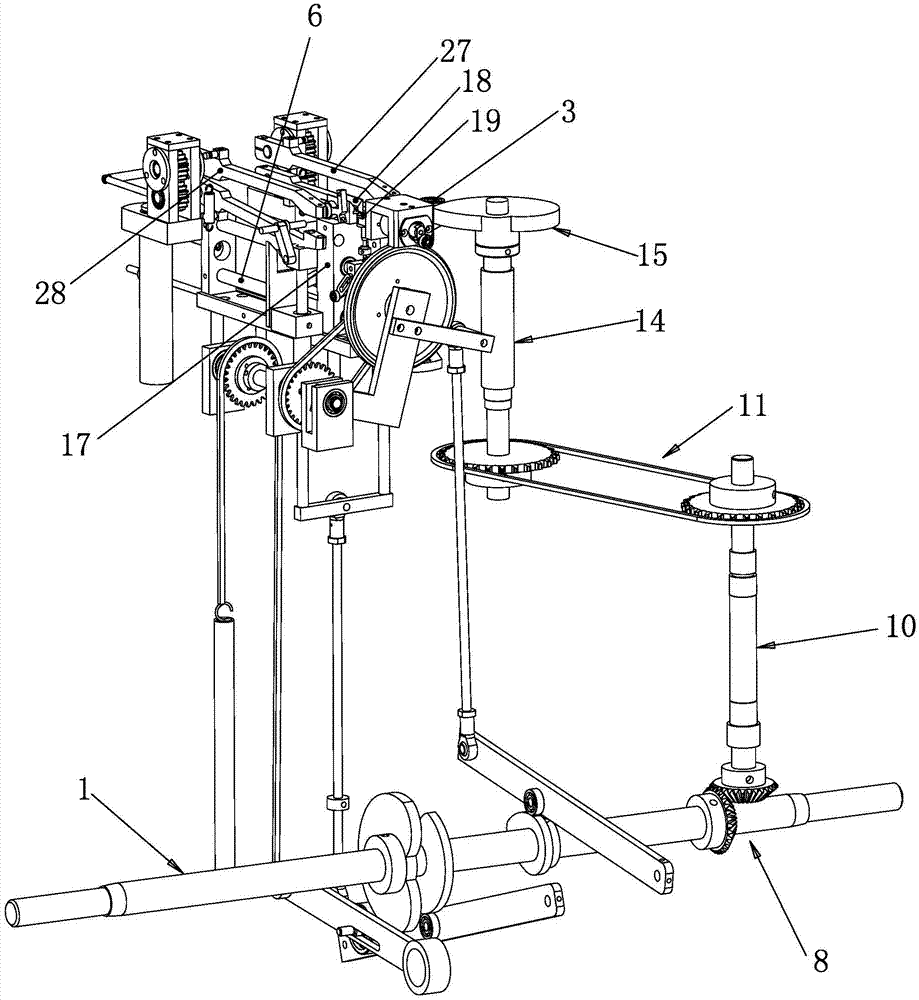

[0040] Example: see attached Figure 4~7 As shown in the figure, there is an acupuncture needle automatic handle-winding machine for sending needles and loading heads. The turntable of the handle-winding machine rotates around a vertical line. The outer periphery of the turntable is provided with a workpiece clamping device 19, and the workpiece clamping device 19 is rotatably supported on the turntable. above, the axis of rotation is horizontal, the workpiece clamping device 19 is used to clamp the wire ring 7, and two wire segments 9, 9' are extended on the wire ring 7; , the drive shaft 1 rotates under the drive of the driving device, the drive shaft 1 is connected to a camshaft 14 through a rotation transmission mechanism, the camshaft 14 is axially vertical, and the camshaft 14 is provided with a cam 15;

[0041] A sliding seat 17 is horizontally slidably connected to the frame of the handle winding machine, and the sliding seat 17 corresponds to the workpiece clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com