Production technology of red date concentrated clear juice

A production process, jujube juice technology, which is applied in food processing, food heat treatment, food processing, etc., can solve the problems of low concentration of soluble solids, affecting the concentration of red jujube juice, and high content of soluble substances, so as to shorten the rehydration time and improve the rehydration time. Water effect, effect of accelerated dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

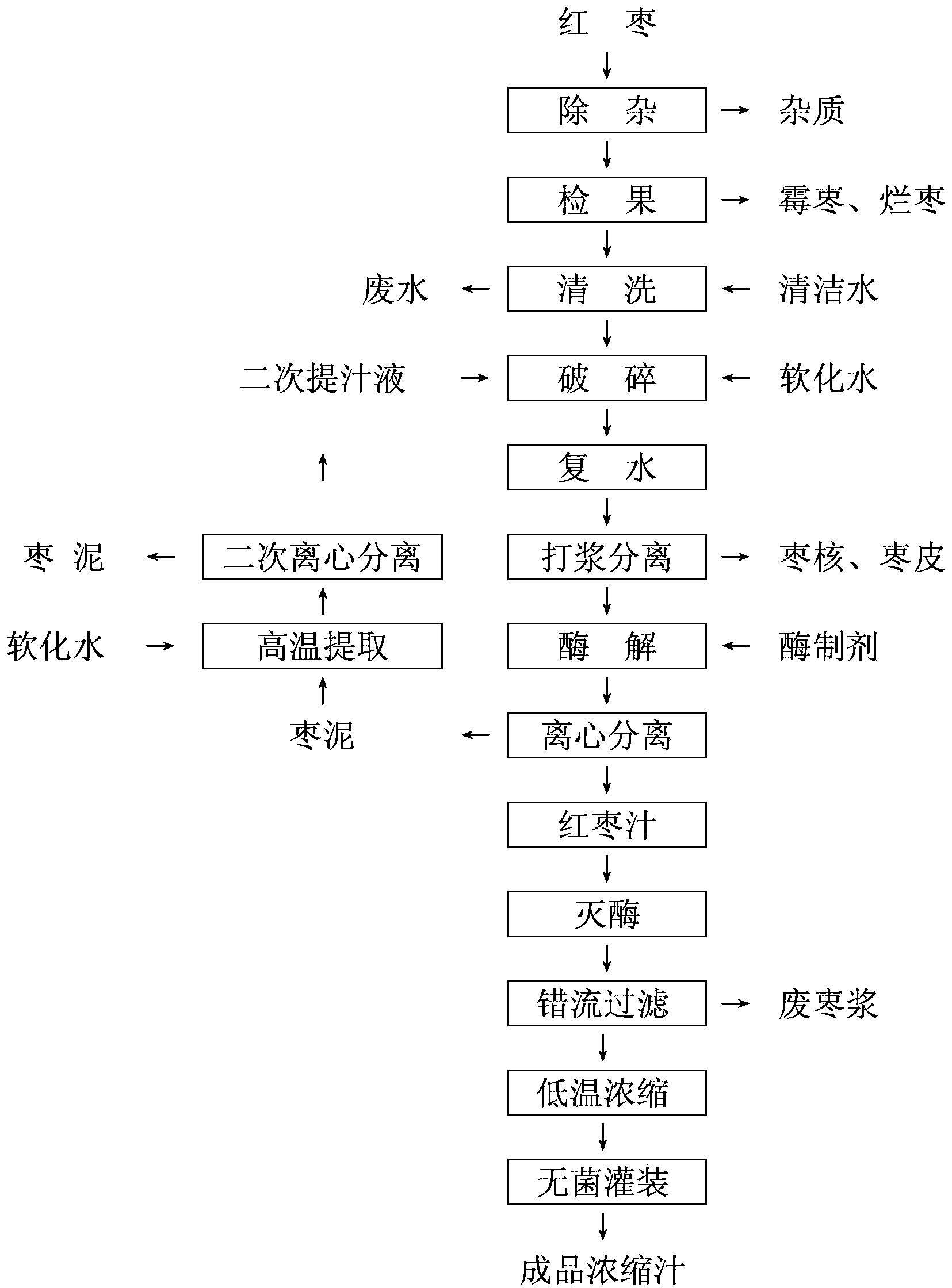

Image

Examples

Embodiment 1

[0045] Embodiment 1: (with Shandong Jinsixiaozao as raw material)

[0046] The raw material Jinsi Xiaozao was weighed 1200g after manual removal of impurities and selection, cleaned, manually crushed, added 4200ml of high-temperature extraction juice (sugar content 2.3%) and 1800ml of demineralized water, under the condition of a water bath temperature of 50°C, Start the stirring crusher every 5 to 10 minutes to crush the red dates, make the red dates into jujube pulp, and keep it for 40 minutes; filter to remove the jujube core and jujube skin; add 3ml of pectinase and 0.5ml of amylase, Stir at a temperature of 50°C and enzymatically hydrolyze for 60 minutes; the enzymolyzed solution is centrifuged to separate the jujube paste to obtain 4,500ml jujube turbid juice with a sugar content of 12.3Bix; add 4,000ml of demineralized water to the separated jujube paste, Under certain conditions, keep it for 60 minutes, remove the jujube paste by centrifugation, and obtain 4200ml of ex...

Embodiment 2

[0047] Embodiment 2: (with Shanxi Junzao as raw material)

[0048] 2000g of raw jujube was manually removed and selected, washed, manually broken into pieces, 7300ml of high-temperature extraction juice (sugar content 2.8%) and 2700ml of demineralized water were added, and the temperature of the water bath was 50°C. Start the stirring crusher once every 5-10 minutes to crush the red dates, and make the red dates into jujube pulp for 40 minutes; filter to remove the jujube core and jujube skin; add 5ml of pectinase and 1ml of amylase, at temperature Stir at 50°C, enzymolyze for 60 minutes; centrifuge the enzymolyzate to separate the jujube paste, and obtain 7,500ml jujube turbid juice with a sugar content of 12.8%; add 7,000ml of demineralized water to the separated jujube paste, and put it under the condition of 95°C , maintained for 60 minutes, removed the jujube paste by centrifugation, and obtained 7300ml of extracted juice with a sugar content of 2.8%; the red jujube turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com