Column for cabinet door frame and cabinet door frame using the column

A technology for door frames and cabinets, which is applied in the field of cabinet door frames and columns for cabinet door frames. It can solve problems affecting the flatness of door frames, etc., and achieve the effects of improving installation accuracy, avoiding looseness, and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

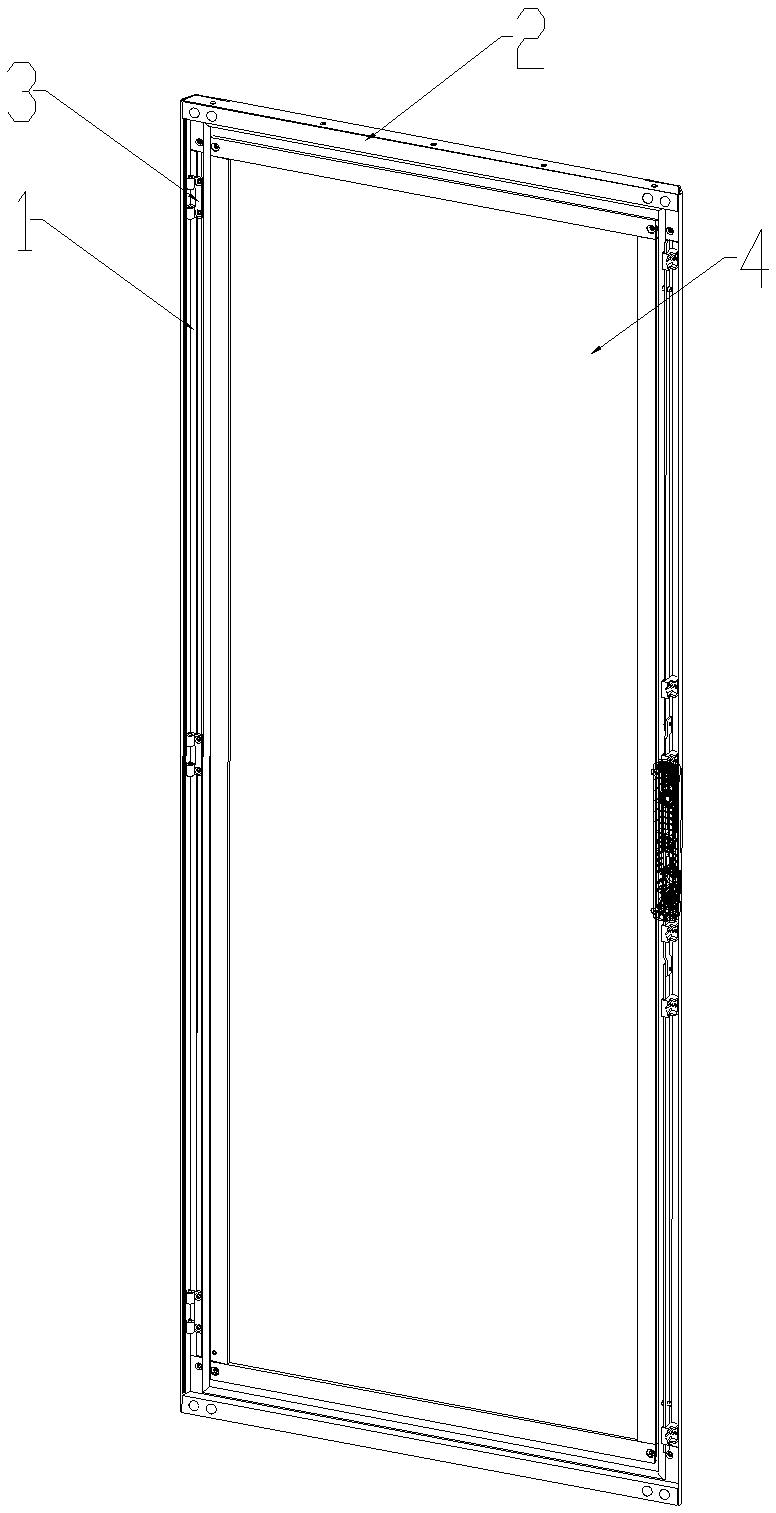

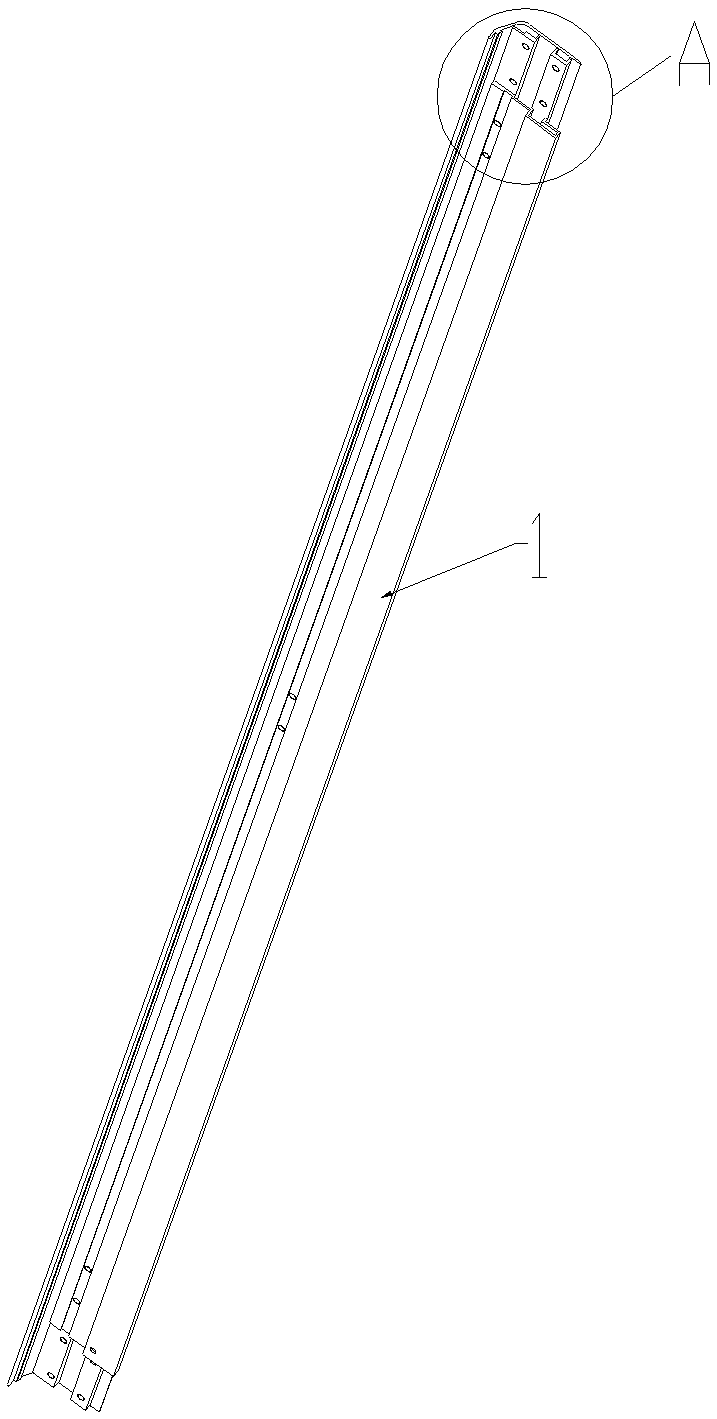

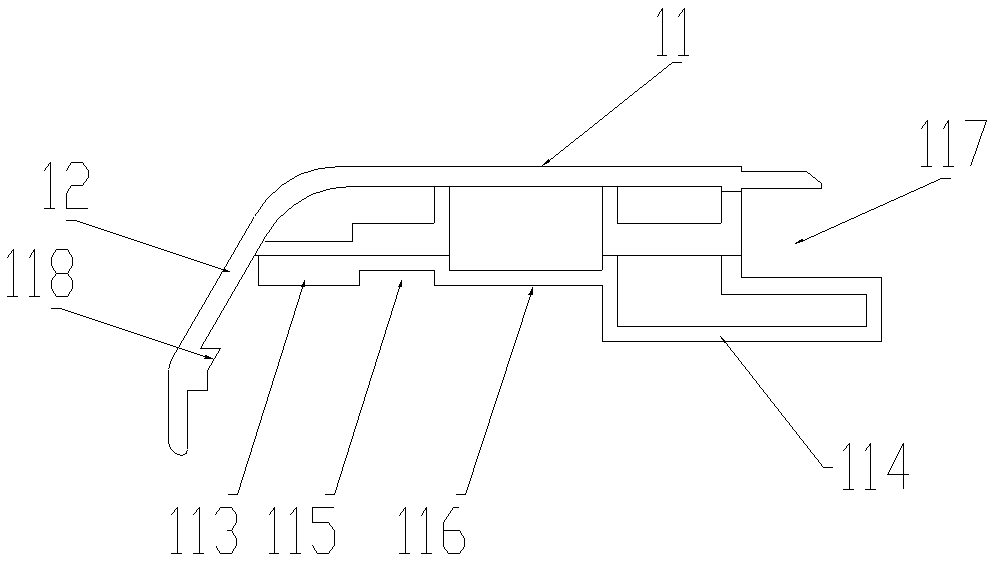

[0023] Example 1 of the cabinet door frame of the present invention is as Figure 1-4 As shown: the cabinet door frame includes a column 1 and a cross beam 2. The column 1 is made of aluminum profiles. The column 1 includes a panel 11 and a side panel 12 for shielding the end of the corresponding cross beam 2. The end of the panel 11 is provided with a connecting structure located inside the panel for installing the cross beam 2, and a side panel 12 and the panel 11 are formed Included angle, the junction of the panel 11 and the side plate 12 has a rounded transition part, which beautifies the appearance of the cabinet door frame. The inner side of the panel 11 is provided with a hollow convex portion 111, and the connection structure is a threaded hole 112 provided on the hollow convex portion 111. The hollow convex portion 111 has a plane parallel to the panel. The inner side of the panel 11 is also provided with stepped bosses between the connecting structures at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com