Backlight module and liquid crystal display device

A liquid crystal display device and backlight module technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., and can solve problems such as increasing the thickness of the backlight module, increasing the thickness of the frame, and unfavorable development of thinner display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

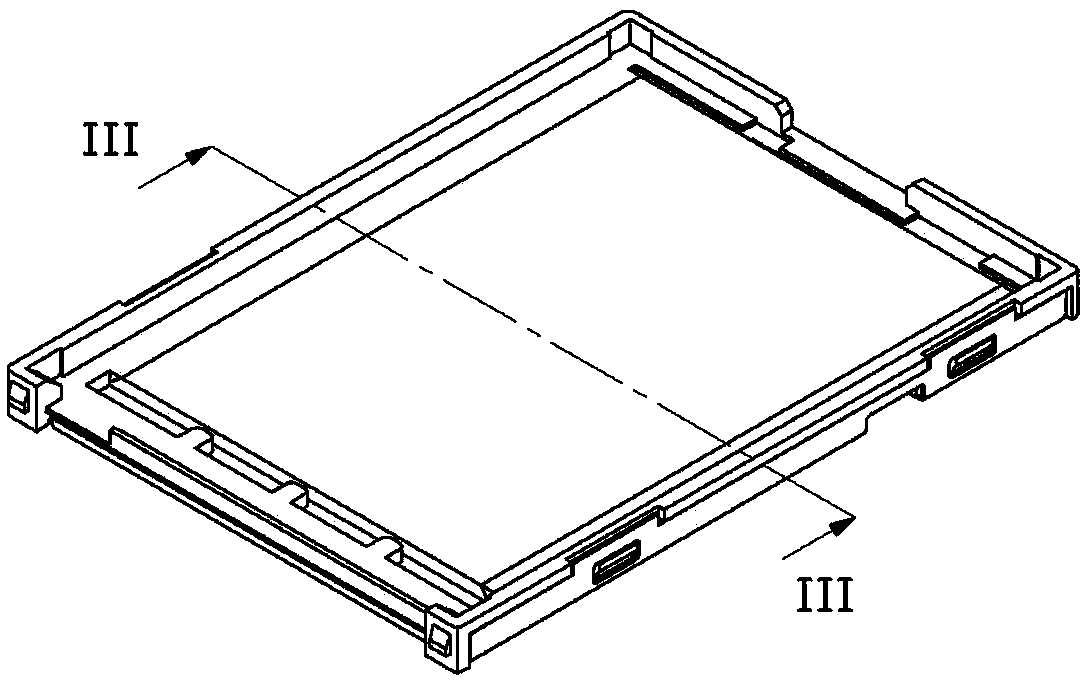

[0036] see figure 1 , which is a schematic diagram of the first embodiment of the liquid crystal display device of the present invention. The liquid crystal display device 1 includes a top cover 10 , a liquid crystal panel 20 , and a backlight module 40 disposed adjacent to the liquid crystal panel 20 . The backlight module 40 includes an optical film set 420 , a light guide plate 430 , a light source 440 , a reflector 460 , a frame 450 and a back plate 480 . The upper cover 10 cooperates with the back plate 480 to accommodate the liquid crystal panel 20 and the backlight module 40 therein.

[0037] The light guide plate 430 includes a light emitting surface 431 , a bottom surface 432 opposite to the light emitting surface 431 , a plurality of side surfaces 434 connecting the light emitting surface 431 and the bottom surface 432 , and at least one notch 436 . The size of the bottom surface 432 of the light guide plate 430 is greater than the size of the light-emitting surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com