Fastener and manufacturing method thereof

A technology of fasteners and fastener clips, which is applied in the direction of connecting components, building structures, and detachable fasteners for friction clamping, etc., can solve the problems of easy loosening, general anti-skid effect, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the features in the various embodiments of the present application may be combined or replaced with each other.

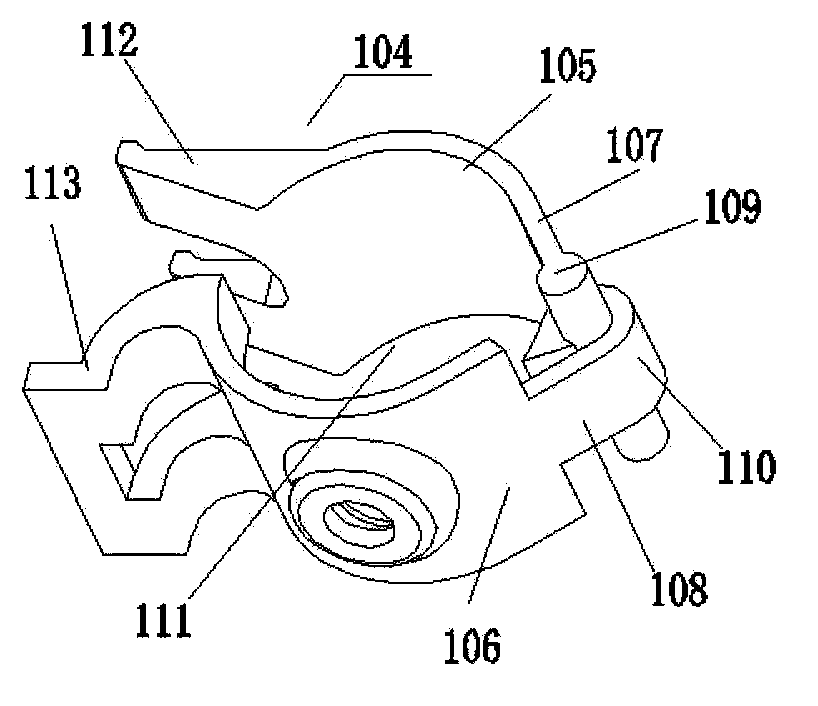

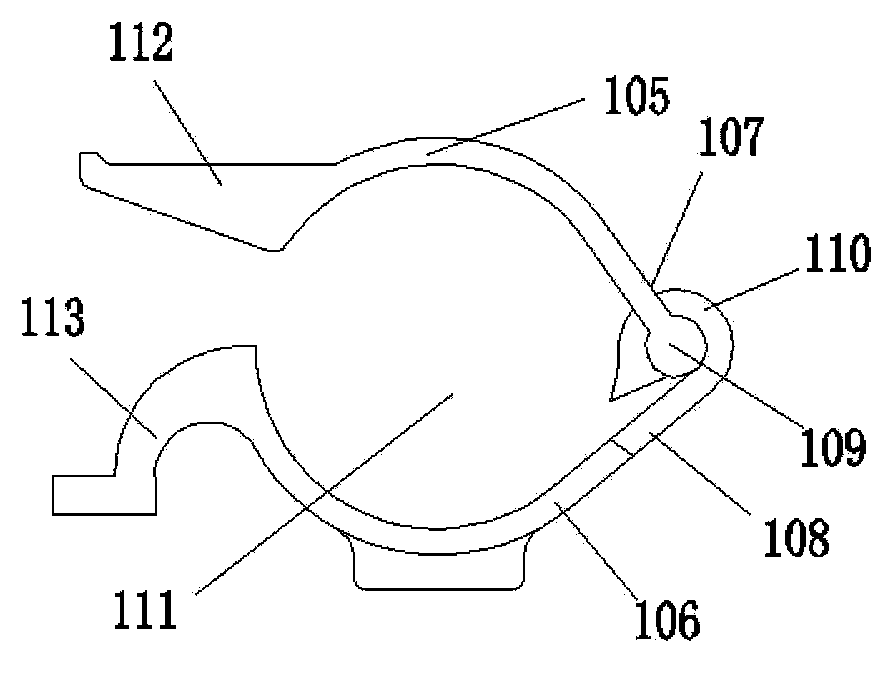

[0125] The invention provides a fastener for clamping an object, the fastener comprises a first clamping arm and a second clamping arm, the first end of the first clamping arm and the first end of the second clamping arm are connected to each other through a rotatable connection mechanism A rotatable connection forming a cavity between the first and second clamp arms for accommodating the object while clamping the object, wherein the rotatable connection mechanism includes a pin shaft and winding around the pin shaft and winding around the pin shaft a rotatable coil connected at its first end to or as part of one of the first and second clamp arms, the pin connected to the other of said first and sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com