Loading machine for particle materials

A technology of granular material and charging machine, applied in the field of charging machine for granular material, can solve the problems of low efficiency, high charging cost, difficult maintenance, etc., and achieve the effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

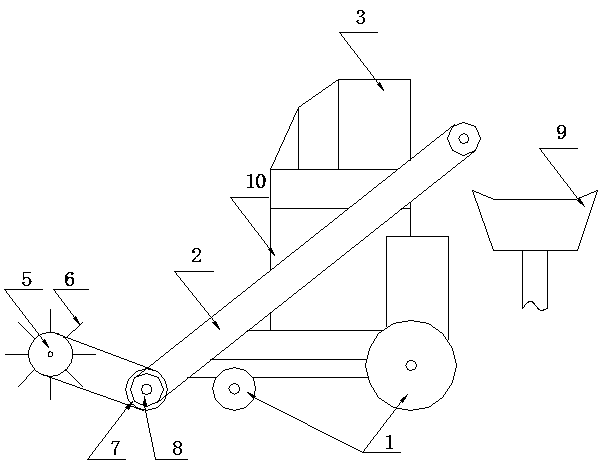

[0010] Specific embodiment 1: 2 conveyor belts are installed on the frame: as Figure 1~3 , a charging machine for granular materials, which is composed of a feeding wheel 5, a conveyor belt 2 and a walking wheel 1. The feeding wheel 5 is driven to rotate by a motor, and its left and right ends are coaxially symmetrically provided with an auger 4 and an auger 4. The rotation makes the materials on both sides move to the dial wheel 5, and at the same time, the driving shaft of the dial wheel 5 and the driven wheel 8 of the conveyor belt are in the coaxial center position, and the motor speed can be adjusted according to the material condition to adjust the loading efficiency; the charging machine is powered by a gasoline engine Drive, conveyor belt 2 is fixed on the frame 10. Such as Figure 4 As shown, the dial teeth 6 on the dial wheel 5 are plate-shaped.

[0011] Wherein, the shifting wheel 5 can also be driven and rotated by the conveyor belt 2, and at this time, the shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com