Screen printing machine

A technology of screen printing machine and printing device, which is applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., and can solve the problems of easy drying of metal paste, affecting printing quality, and affecting the performance of silicon wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

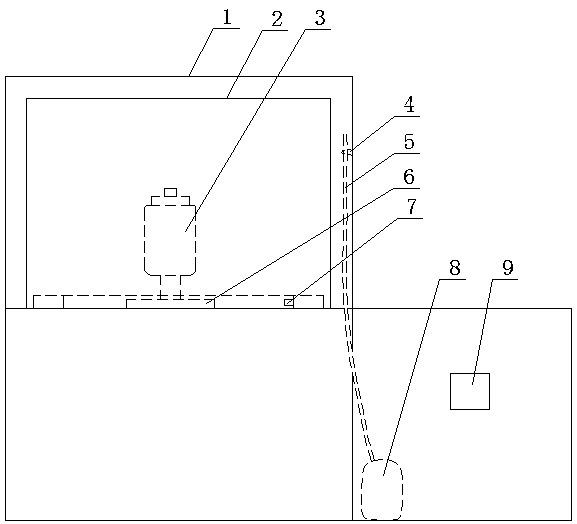

[0007] Such as figure 1 As shown, it is a screen printing machine, including a frame 1, a printing platform 6 and a printing device 3 are arranged in the frame 1, the door 2 is hinged on the frame 1, a humidifier 8 is arranged in the frame 1, and a humidifier 8 is arranged on the humidifier 8 The humidifying pipe 5 is connected, and the other end of the humidifying pipe 5 is arranged on the upper part of the frame 1 through the connecting piece 4 . The printing platform 6 is connected with a humidification sensor 7, and the signal output end of the humidification sensor 7 is connected with a temperature and humidity controller 9, and the temperature and humidity controller 9 controls the humidifier 8 according to the setting requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com