Forming device and method of operation thereof

A technology of a molding device and an operating method, applied to other household appliances, household appliances, optical components, etc., can solve the problems of low alignment accuracy, difficult to correct, center deviation, etc., to increase product production efficiency, and increase the ease of manufacturing and assembly. , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

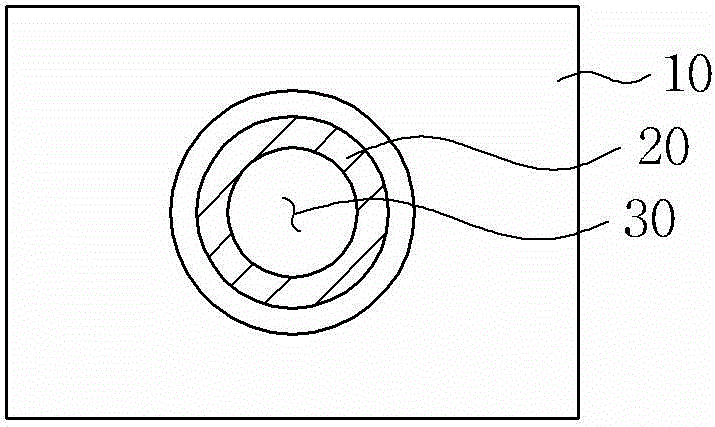

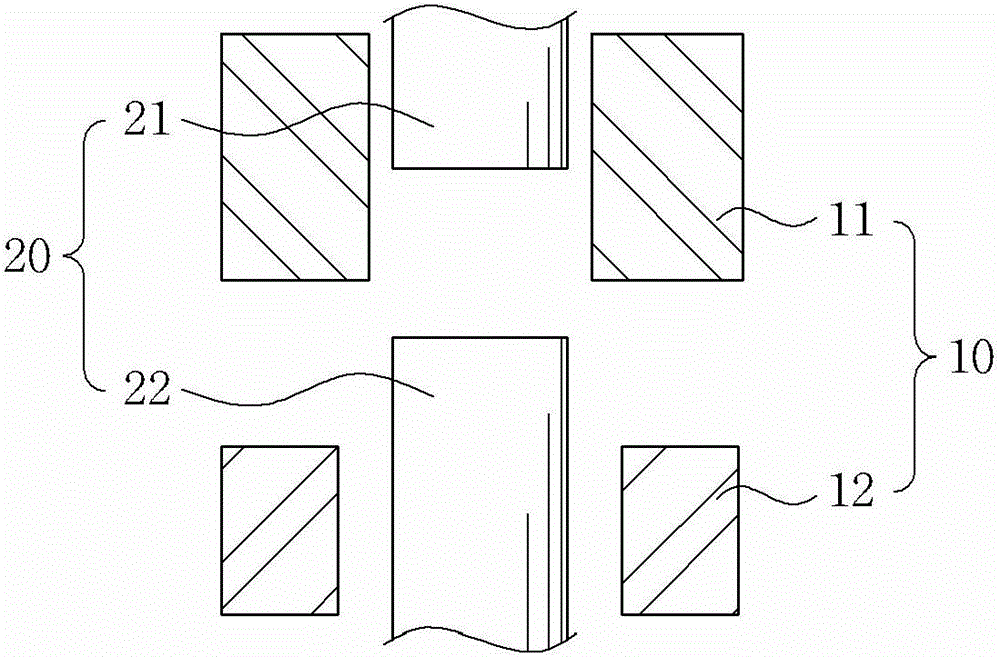

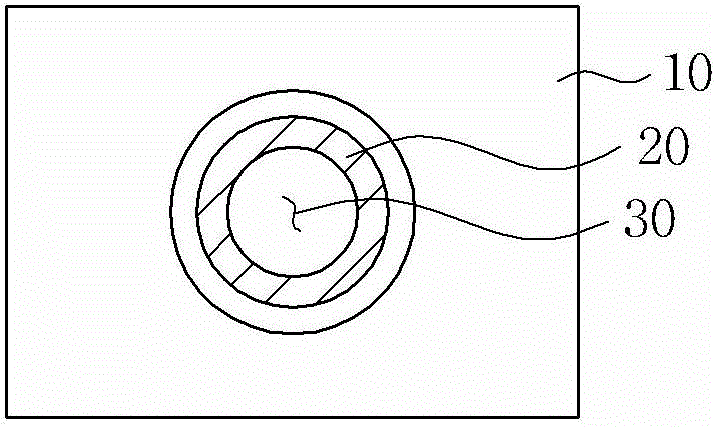

[0042]The purpose, specific advantages, and innovative features of the present invention will become more apparent from the following detailed description and preferred embodiments associated with the accompanying drawings. In this specification, when referring to the components of each drawing, the reference symbols are limited to the same components, and even if they are shown in different drawings, the same symbols are used as much as possible. In addition, terms such as "one side", "the other side", "first", and "second" are used to distinguish one constituent element from other constituent elements, and the constituent elements themselves are not limited by the terms. In particular, the upper and lower directions of the present invention are Figure 2b Based on the drawing shown in , the part forming the upper core and upper formwork on one side is called "upper part", and the part on the other side forming the lower core and lower formwork plate is called "lower part". ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com