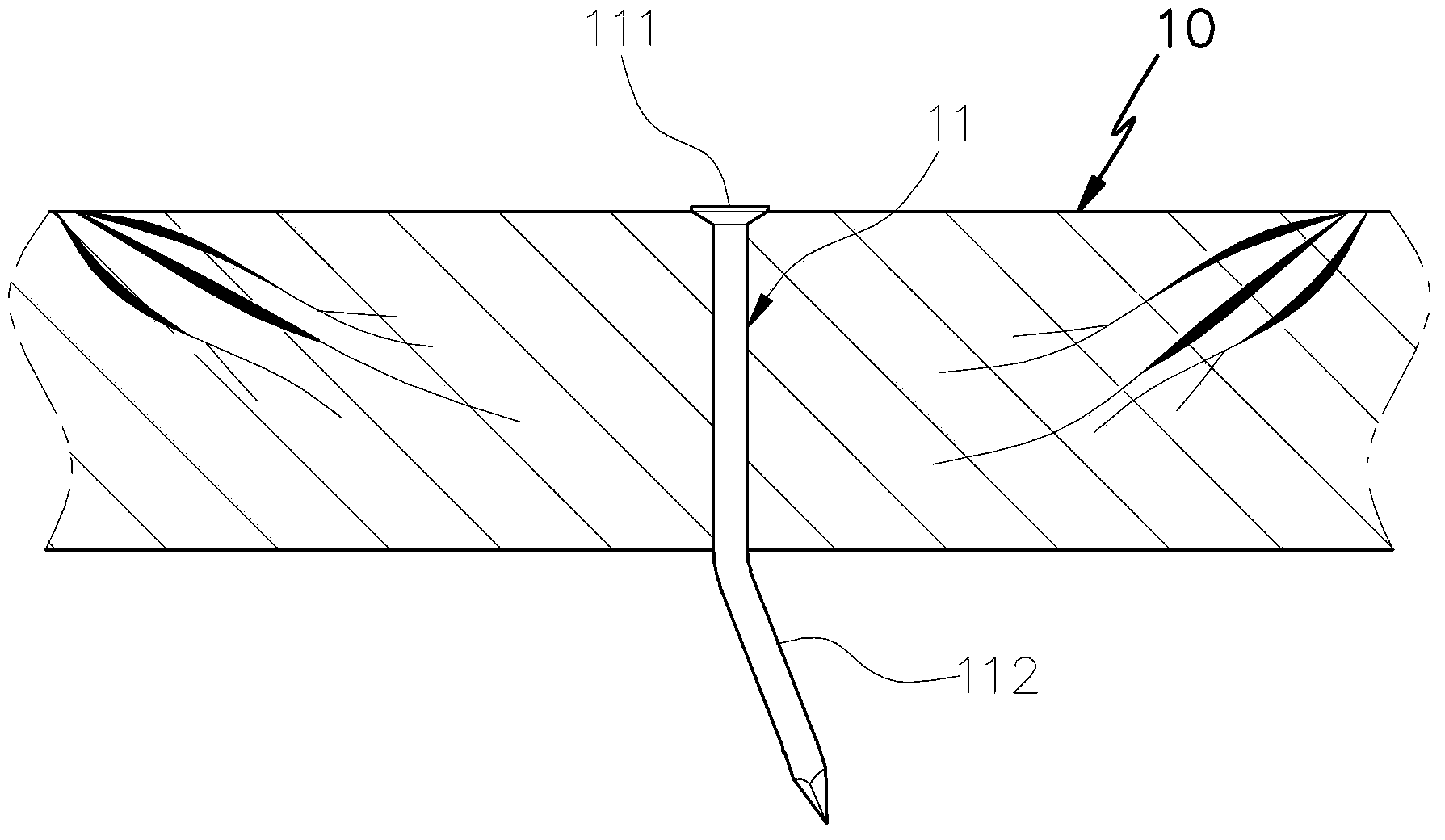

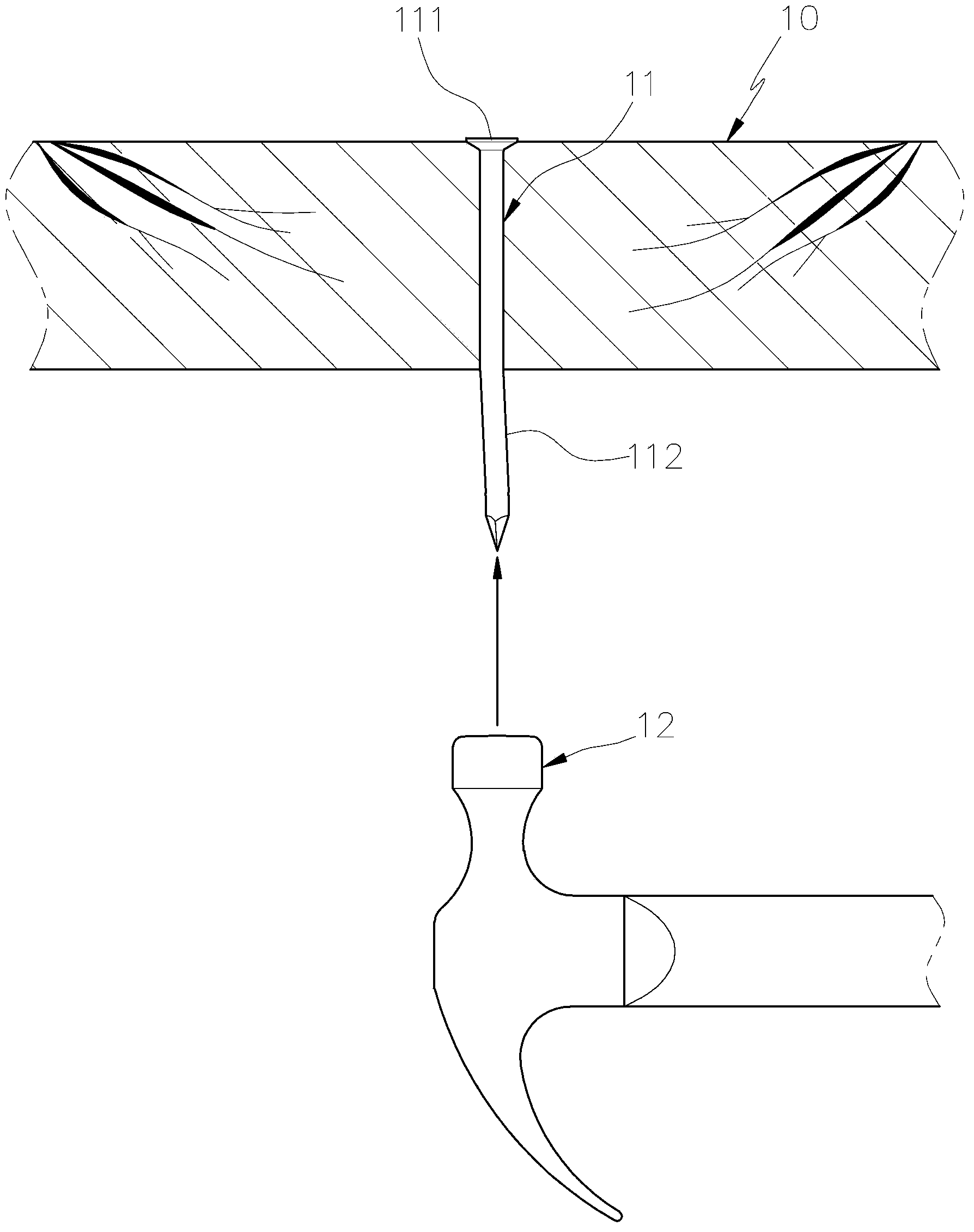

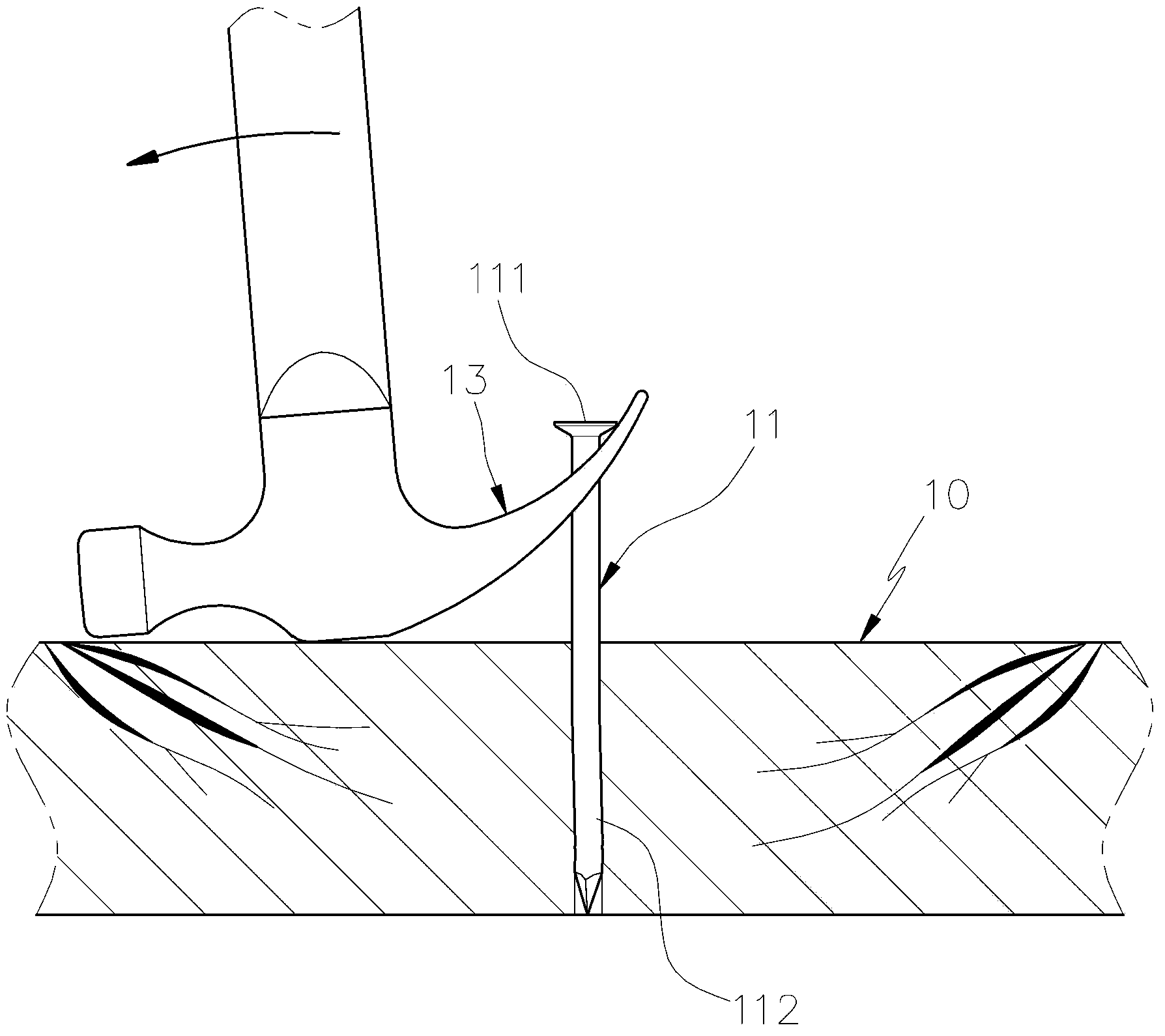

Nail dismounting device

A technology of nail extractor and impact rod, which is applied in the field of plate removal tools, can solve the problems of laborious turning and straightening, damage to screw teeth, and difficulty in accurate knocking, etc., to achieve labor-saving turning, stable nailing operation, and easy removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable your examiner to have a further understanding of the present invention, hereby cite a preferred embodiment together with the accompanying drawings, and describe it in detail as follows:

[0048] see Image 6 , Figure 7 The nail remover 40 of the first embodiment of the present invention is provided with a hollow tubular outer casing 41 made of a high-hardness metal material. The hole 43 abuts against the tube base 42 and is integrated with the outer sleeve 41. A striking rod installed in the outer sleeve 41 has its first end stretched through the through sleeve hole 43 abutting against the tube base 42 with an appropriate length. , and make the through sleeve hole 43 reserve a receiving hole section 431, the second end of the striking rod protrudes from the outside of the second end of the outer casing 41; in this embodiment, the striking rod includes a first striking rod 44 And the second striking rod 45, the first end of the first striking rod 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com