Tubular bag machine and method for operating a tubular bag machine

A hose bag and hose technology, applied in the direction of transportation packaging, transportation and packaging, external support, etc., can solve the problem of difficult positioning of packaging material strips, and achieve simple and reliable work, simple and reliable valve devices, The effect of high storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

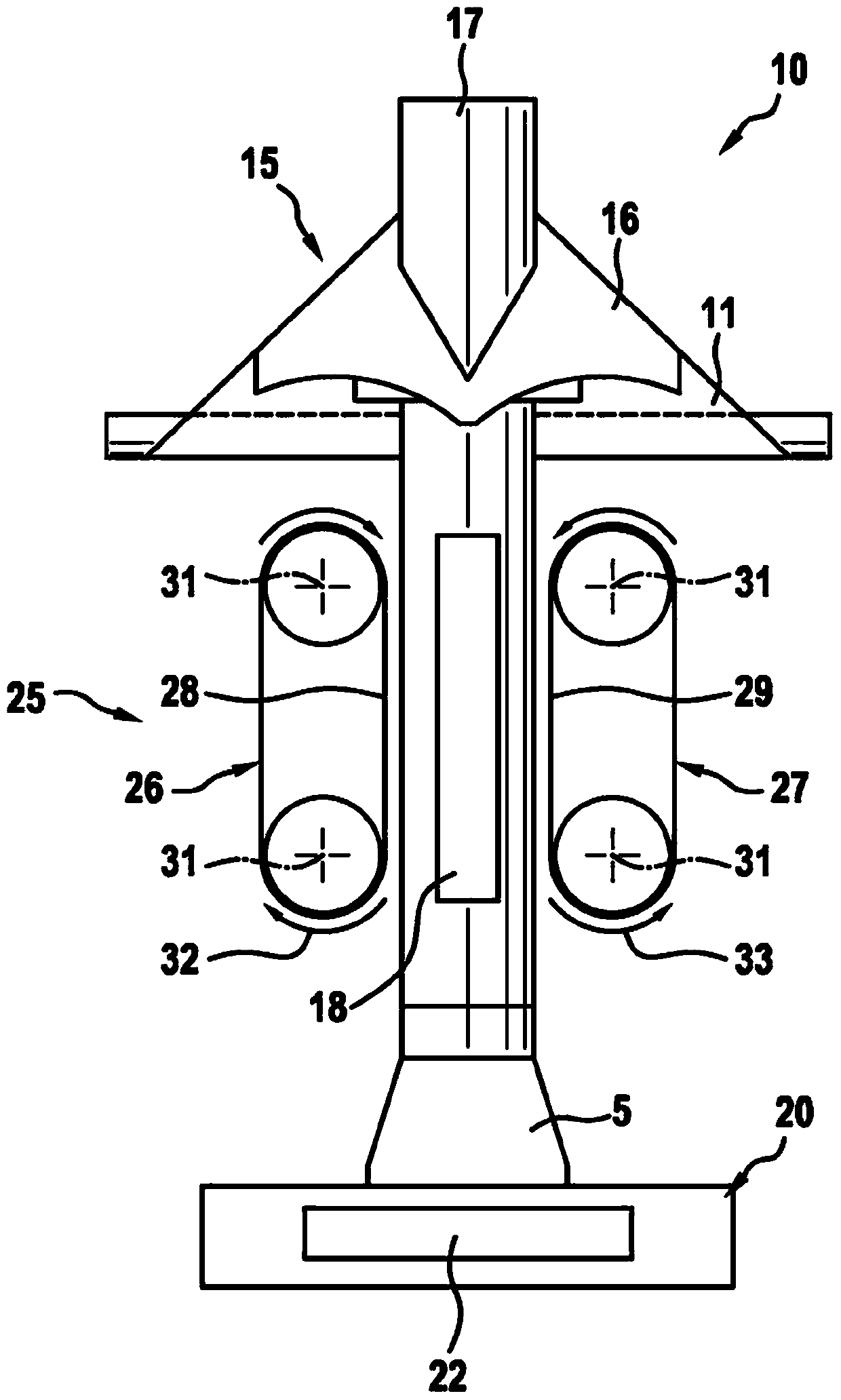

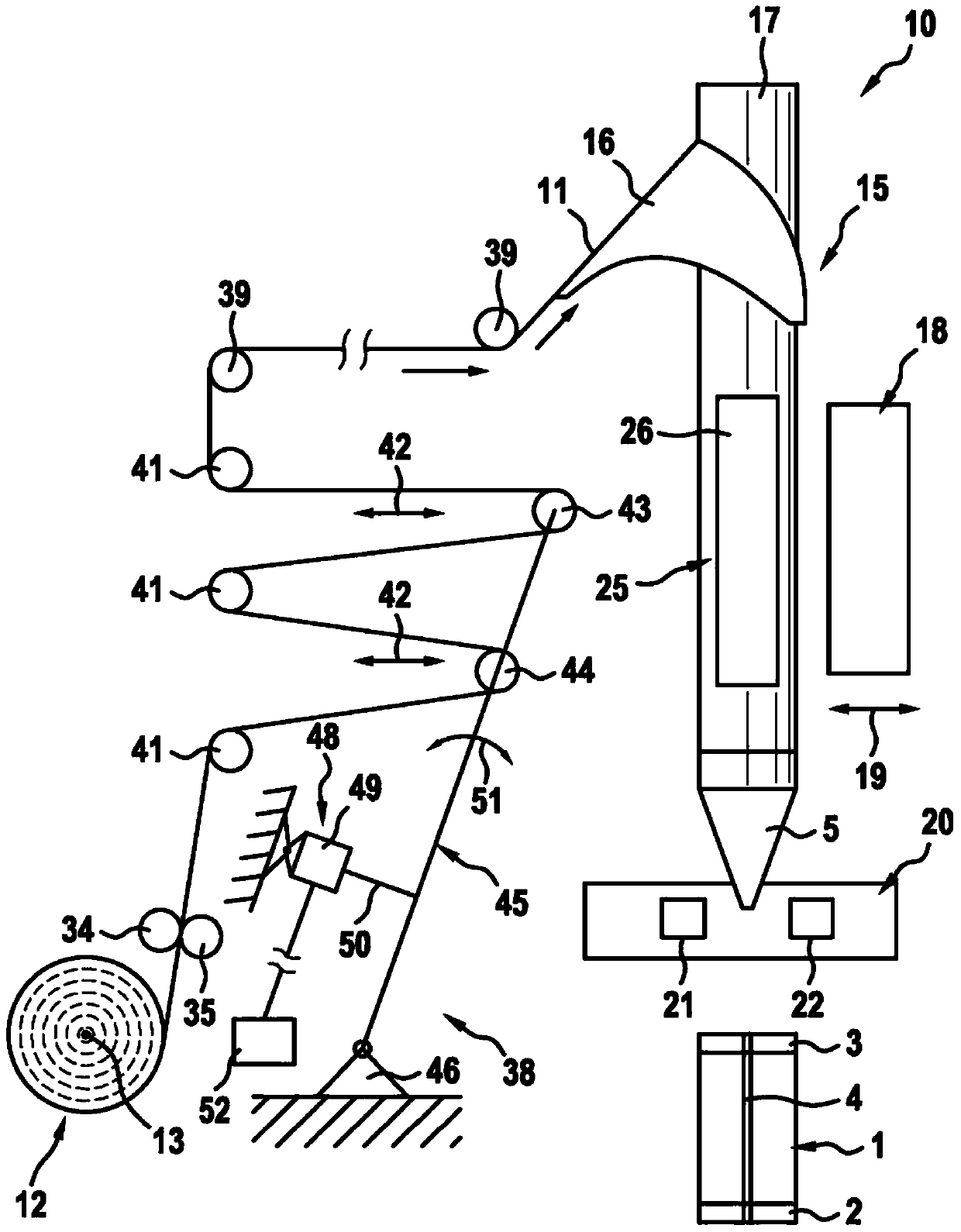

[0014] The drawing shows a tube bag machine 10 according to the invention for producing tube bag packages 1 , in particular filled with food. Hose bag packaging 1 ( figure 2 ) each have a lower transverse seal 2 , an upper transverse seal 3 and at least one longitudinal seal 4 . The tube bag pack 1 is formed from a packaging material web 11 which consists of a heat-sealable material and is stored in the form of a supply roll 12 on a shaft 13 .

[0015] The tube bag machine 10 has a tube forming device 15 which comprises a forming shoulder 16 and a forming tube 17 which is connected to the forming shoulder 16 and which is in particular circular in cross section. In order to form the packaging material tube 5 from the packaging material strip 11, the packaging material strip 11 is drawn onto the forming shoulder 16 and placed around the forming tube 17, wherein the packaging material strips 11 overlap each other in the longitudinal direction The edge area of the vertical se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com