Protection device and method for rotary supporting bearing and driving motor of thickener

A technology of slewing support bearing and driving motor, applied in the field of concentrator, can solve problems such as unsatisfactory use effect, and achieve the effect of perfect function, accurate action and high protection precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

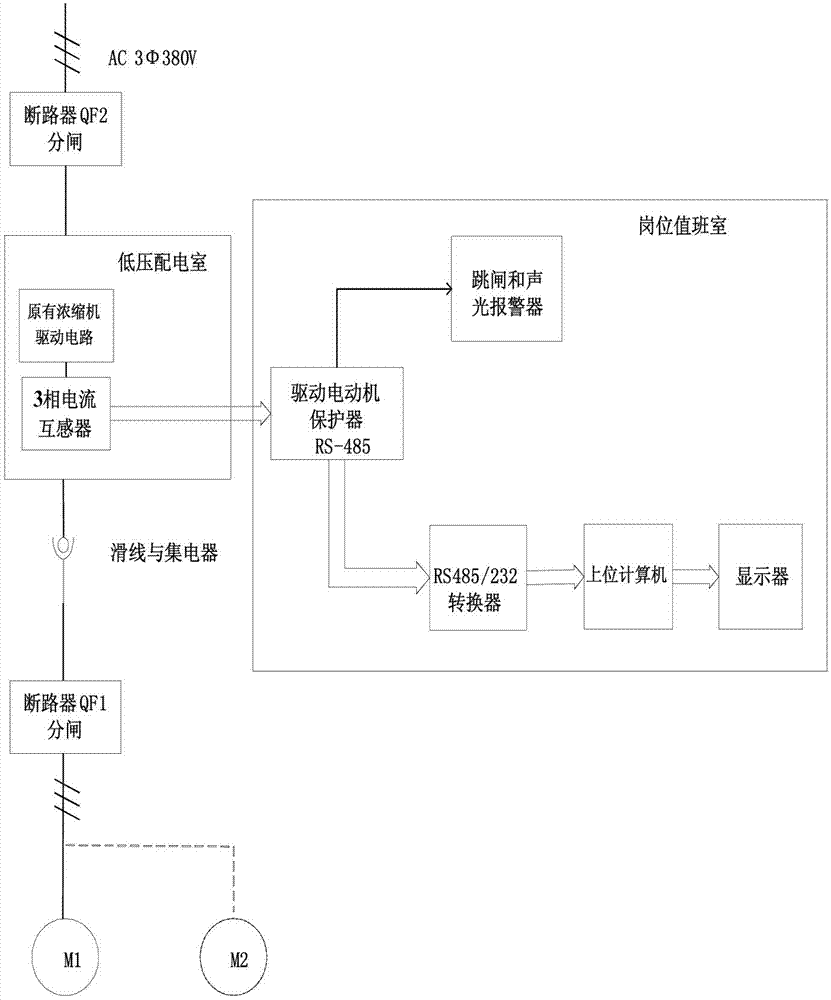

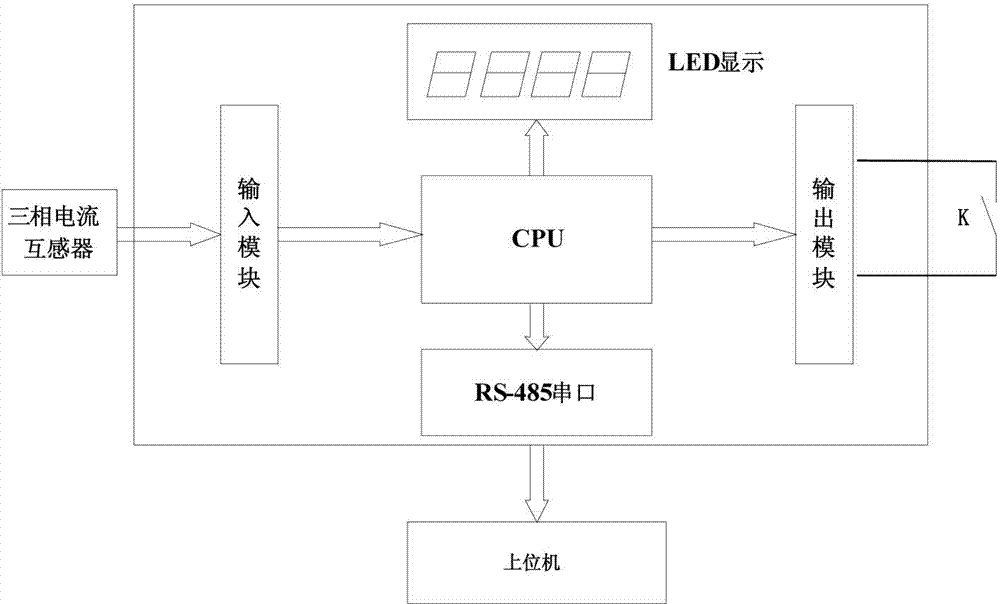

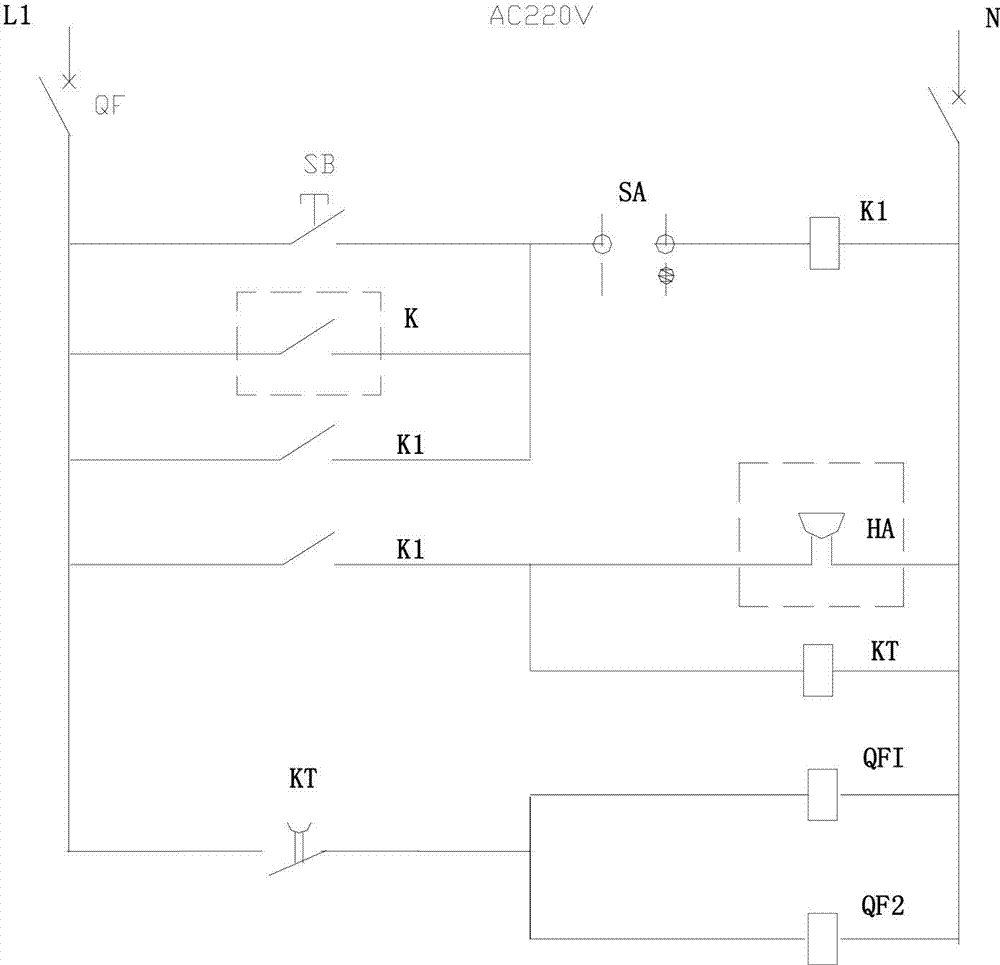

[0049] like figure 1 As shown, the protective device for the slewing support bearing and the drive motor of the concentrator of the present invention includes a drive circuit of the concentrator and a slide wire and a collector connected to the drive circuit of the concentrator, and is characterized in that it also includes a The driving circuit of the concentrator and the three-phase current transformer between the slide wire and the collector, the drive motor protector connected with the three-phase current transformer, and the tripping and sound-light alarm respectively connected with the drive motor protector Devices, RS485 / RS232 converters, the first circuit breaker QF1 in the driving trolley, or the setting between the drive circuit of the concentrator and the three-phase power supply, which is set between the above-mentioned slide wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com