Sampling device and sampling method for gas content of insulating oil

A sampling device and gas content technology, applied in the direction of sampling devices, etc., can solve problems such as the difficulty of sampling insulating oil gas content, achieve the effects of optimizing oil sampling test conditions, improving test accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

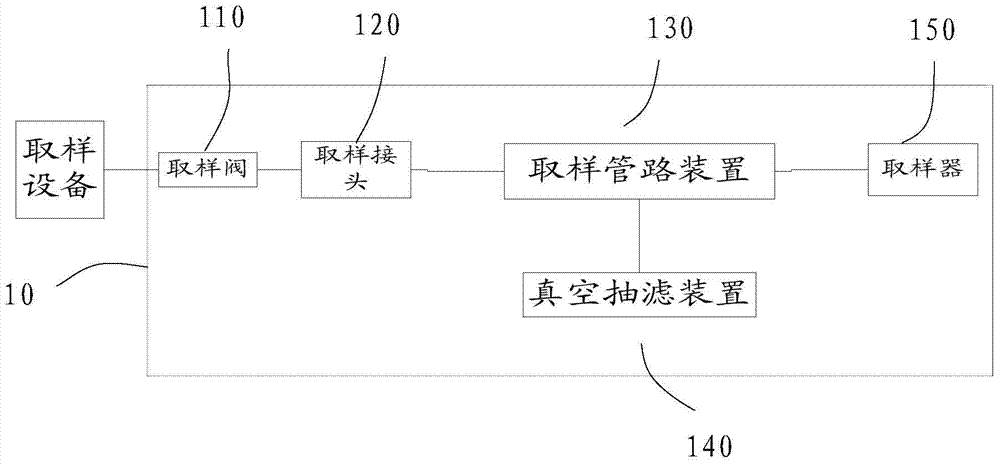

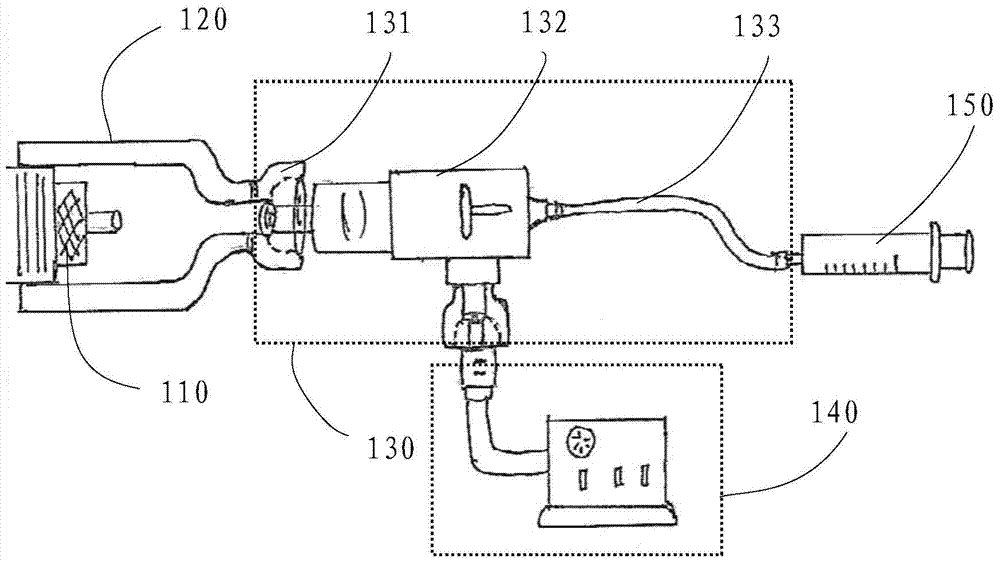

[0044] Such as figure 1 As shown, the present invention provides a sampling device 10 for the gas content of insulating oil, including a sampling joint 120, a sampling pipeline device 130 connected to the sampling joint 120 at one end, and a sampler 150 detachably connected to the other end of the sampling pipeline device 130, And a vacuum filtration device 140 connected to the sampling line device 130 . The insulating oil gas content sampling device 10 is connected with a sampling device, that is, a transformer, the transformer has a sampling valve 110 , and the sampling joint 120 is connected with the sampling valve 110 .

[0045] Before sampling, the sampling pipeline device 130, the sampling valve 110, and the sampling joint 120 are vacuumized through the vacuum filter device 140 connected with the sampling pipeline device 130, and the whole sampling process is carried out in a sealed environment, avoiding the The gas outside the process is mixed into the oil sample, and ...

Embodiment 2

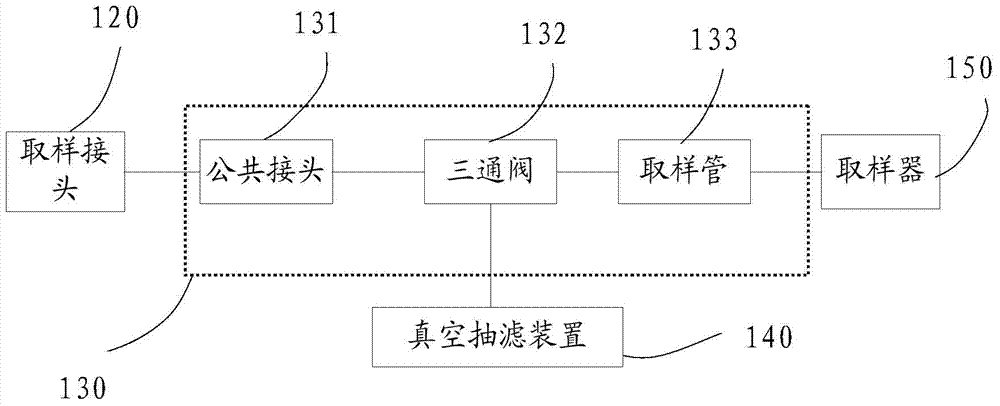

[0058] Such as Figure 4 As shown, the sampling pipeline device 130' includes a sampling tube 133, and a common joint 131 connected to one end of the sampling tube 133, and the common joint 131 is connected to the sampling joint 120; it also includes a three-way valve 132 connected to the other end of the sampling tube 133, The other end of the three-way valve 132 is detachably connected to the sampler 150 , and the third end of the three-way valve 132 is connected to the vacuum filtration device 140 . The sampling pipe 133, the vacuum filter device 140 and the sampling pipe 133 are connected together by the three-way valve 132, so as to facilitate the vacuuming process on the sampling pipe 133, the sampling joint 120, the sampling valve 110 and the like. Moreover, through this connection method, the three-way valve 132 and the vacuum filter device 140 are arranged at the end of the sampling device, and the vacuuming operation can be performed away from the charged equipment, ...

Embodiment 3

[0061] Such as Figure 5 As shown, the sampling pipeline device 130 "includes a sampling tube 133, and a common connector 131 connected to one end of the sampling tube 133, and the common connector 131 is connected to the sampling connector 120; it also includes a three-way valve 132 whose two ends are connected to the middle of the sampling tube 133 , the third end of the three-way valve 132 is connected with the vacuum filtration device 140; the sampler 150 is detachably connected with the other end of the sampling tube 133. Utilize the three-way valve 132 to connect the sampling tube 133, the vacuum filtration device 140 and the sampling tube 133 Together, it is convenient to vacuumize the sampling tube 133, sampling joint 120, sampling valve 110, etc., and can select a suitable position on the sampling tube 133 for vacuuming according to the actual situation, which has strong adaptability.

[0062] Compared with Embodiment 1, the difference is that the installation positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com