Engine heat balancing performance bed tester and engine heat balancing performance bed testing method

A technology for engine bench and bench testing, which is applied in the direction of engine testing, measuring devices, internal combustion engine testing, etc., and can solve problems such as inability to test engine heat balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

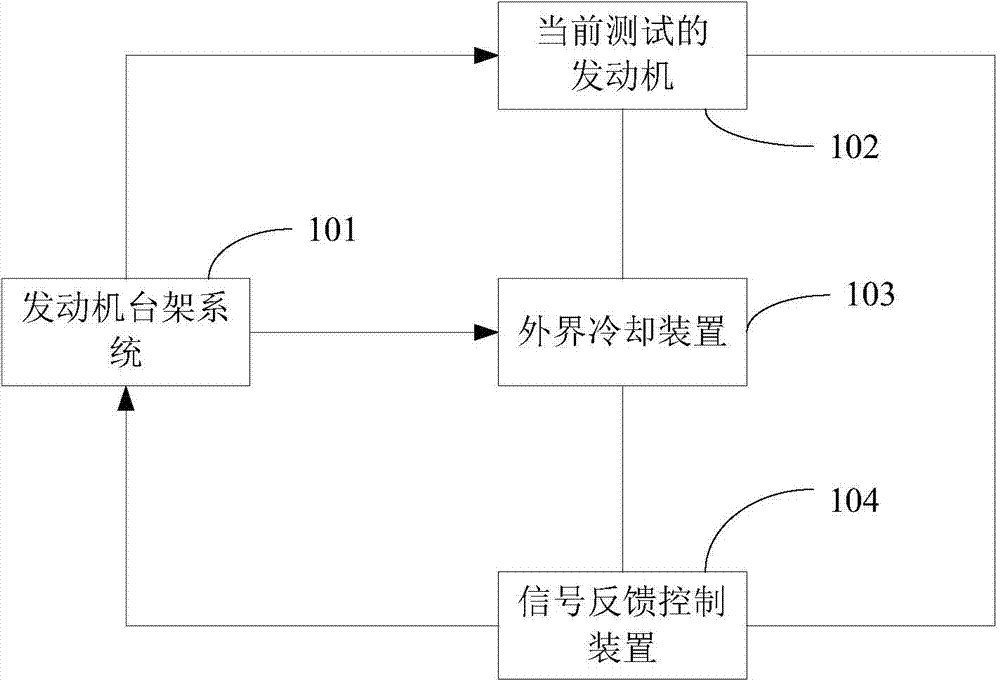

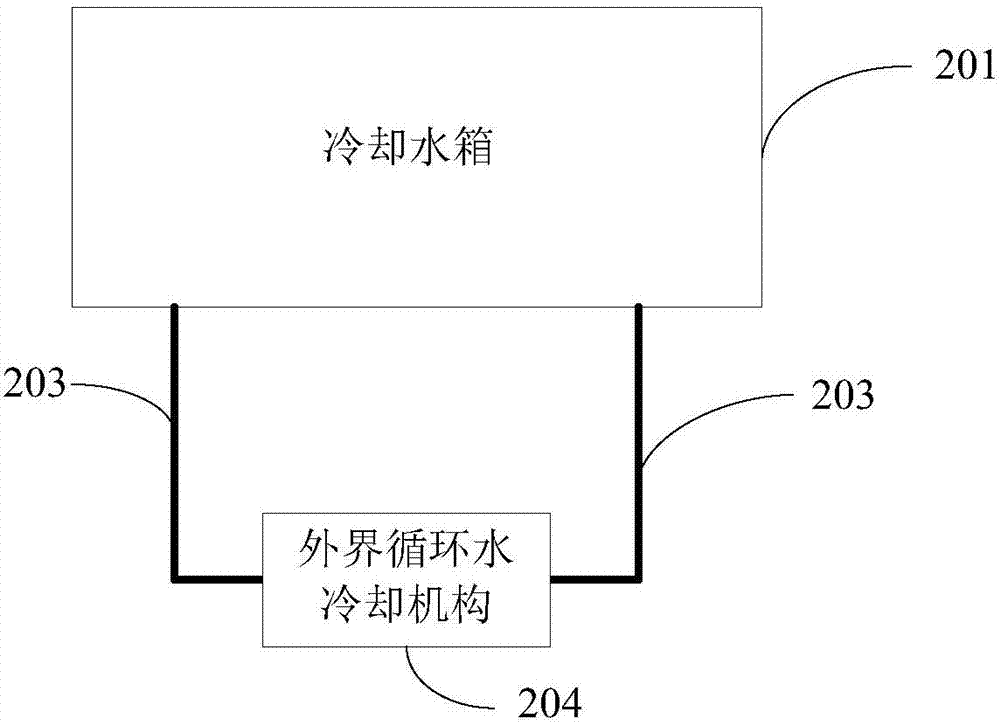

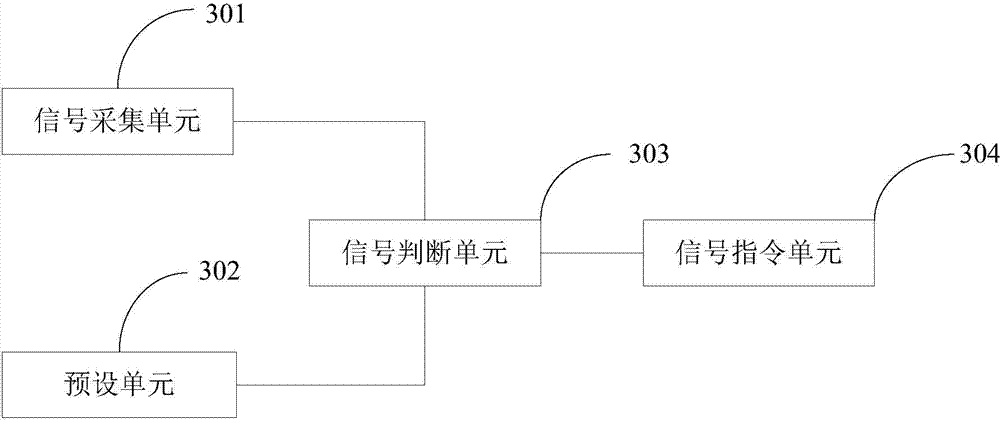

[0072] Such as figure 1 Shown is a schematic structural diagram of an engine heat balance performance bench test device provided by the present invention, including an engine bench system 101 , an external cooling device 103 and a signal feedback control device 104 . Wherein, the engine bench system 101 is respectively connected with the external cooling device 103, the signal feedback control device 104, and the currently tested engine 102; the external cooling device 103 is used to cool the self-contained cooling equipment of the currently tested engine 102 (not shown in the figure ); the signal feedback control device 104 is used to preset the engine temperature threshold and test time, monitor the temperature of the currently tested engine 102 in rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com