Pressure pulse testing machine

A testing machine and air pressure technology, which is applied in the field of sensor detection, can solve problems such as inaccurate waveform control and inaccurate measurement parameters, and achieve the effects of low cost, high control degree and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

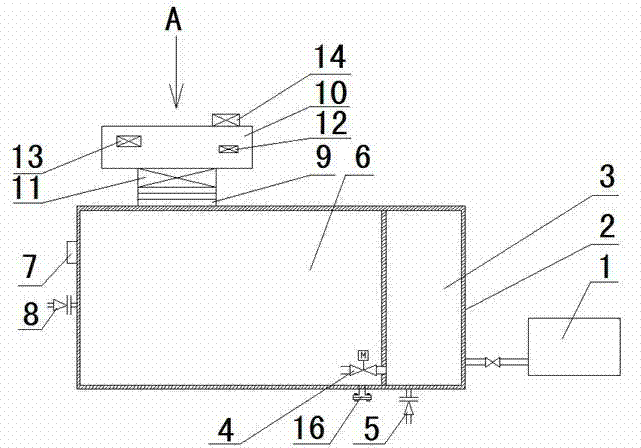

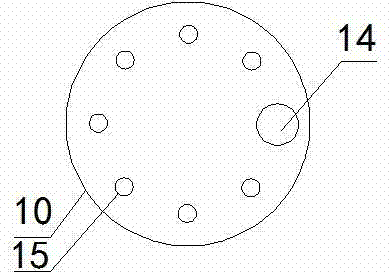

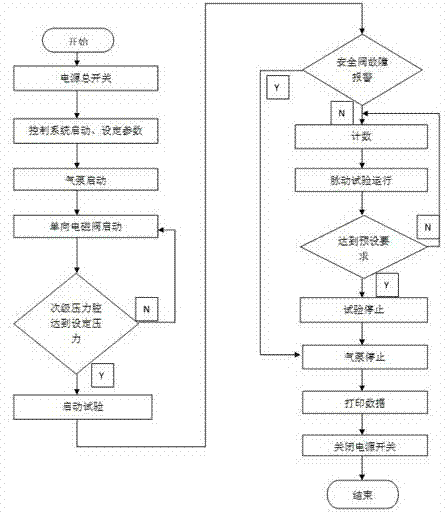

[0020] see Figure 1~2 , the gas storage cabinet includes a primary pressure chamber and a secondary pressure chamber with a one-way solenoid valve. A hand hole 16 is also provided on the cabinet wall where the one-way solenoid valve is located. The primary pressure chamber 3 is connected to the air pump 1. The primary pressure chamber There is also a primary safety valve on the top; a one-way solenoid valve 4 is set between the primary pressure chamber and the secondary pressure chamber 6, the outlet valve port of the one-way solenoid valve faces the secondary pressure chamber, and a pressure valve is installed on the secondary pressure chamber Controller and secondary safety valve; the upper part of the secondary pressure chamber is provided with corrugated 9, intake servo valve, and standard pressure chamber in sequence. A standard pressure sensor 14 with a waveform feedback measurement device is installed on the pressurization hole of the test piece, and a waveform adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com