Excavator bucket tooth and preparation method thereof

A technology of excavator bucket teeth and mass percentage, which is applied in the field of metal materials, can solve the problems of high cost, high energy consumption, and high manganese content, and achieve the effects of prolonging life, improving mechanical properties, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

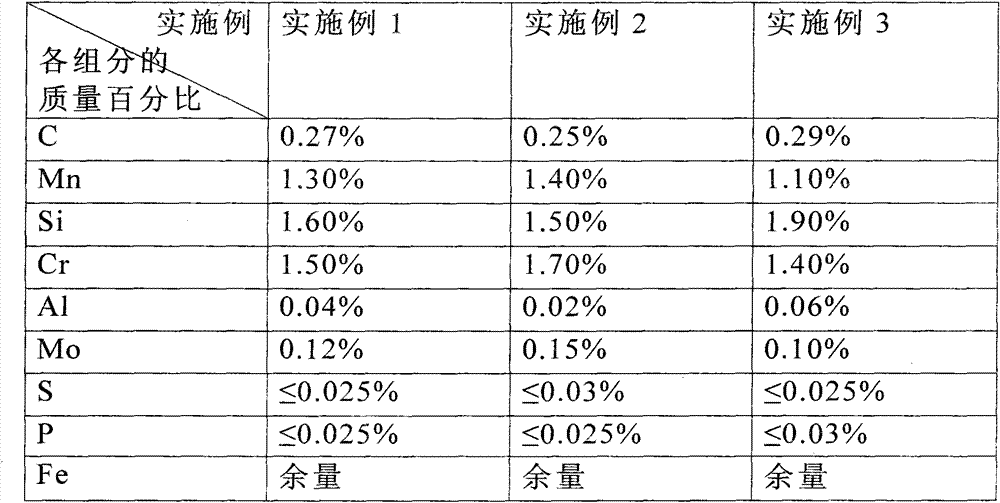

[0029] The constituent elements and mass percentages of the bucket teeth of the excavator in this embodiment are shown in Example 1 in Table 1.

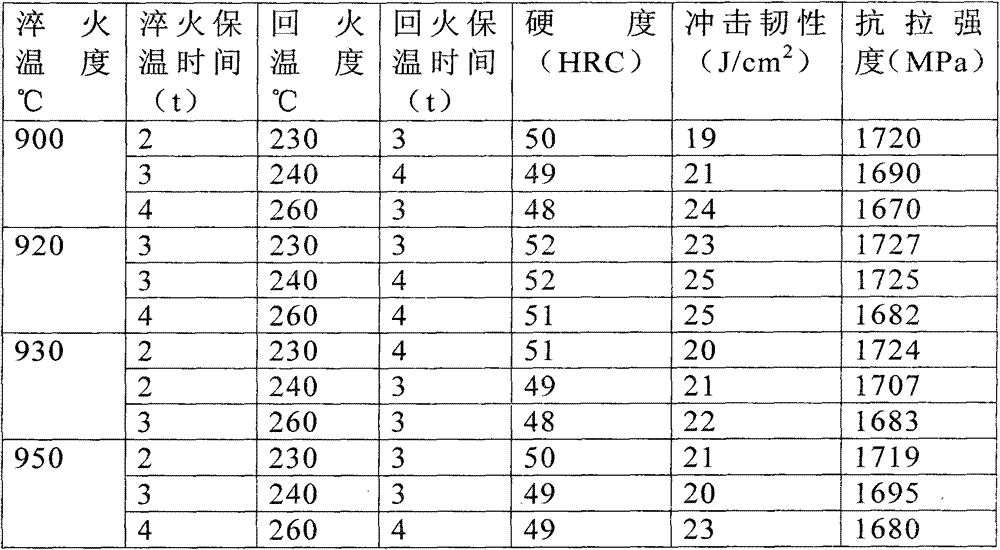

[0030] The constituent elements and mass percentages of excavator bucket teeth have a certain influence on the mechanical properties of bucket teeth, and their preparation process also has a greater impact on the mechanical properties of the final formed bucket teeth. The preparation process of bucket teeth includes casting process and heat treatment process. Among them, the casting process can adopt conventional casting process, and the heat treatment process has the greatest impact on the final mechanical properties of bucket teeth. The heat treatment process includes the steps of quenching and heating, tempering after heat preservation, and air cooling after tempering. In this example, in order to discuss the optimum quenching temperature and tempering temperature, the bucket teeth in this example were heat treated under different...

Embodiment 2

[0037] According to Example 2 in Table 1, the constituent elements and mass percentages of the bucket teeth of the excavator are determined. In this example, the bucket teeth of the excavator go through a casting process and a heat treatment process, wherein the heat treatment process adopts the same process conditions as in Example 1, that is, in In the heat treatment process, quenching is carried out when the temperature is 950°C, and the heat preservation is carried out for 4 hours after quenching; tempering is carried out when the temperature is 260°C, and heat preservation is carried out for 4 hours after tempering. Test its mechanical properties as shown in Table 3:

[0038] Table 3: Mechanical properties of excavator bucket teeth after heat treatment in Example 2 under different conditions

[0039]

[0040] From the above test, after adopting the proportioning of this embodiment, the excavator manufactured by using the process conditions of embodiment 1 has good mech...

Embodiment 3

[0042] According to Example 3 in Table 1, the composition elements and mass percentages of the bucket teeth of the excavator are determined. In this example, the bucket teeth of the excavator go through a casting process and a heat treatment process, wherein the heat treatment process adopts the same process conditions as in Example 1, that is, in In the heat treatment process, quenching is carried out when the temperature is 900°C, and heat preservation is carried out for 2 hours after quenching; tempering is carried out when the temperature is 230°C, and heat preservation is carried out for 3 hours after tempering. Test its mechanical properties as shown in Table 4:

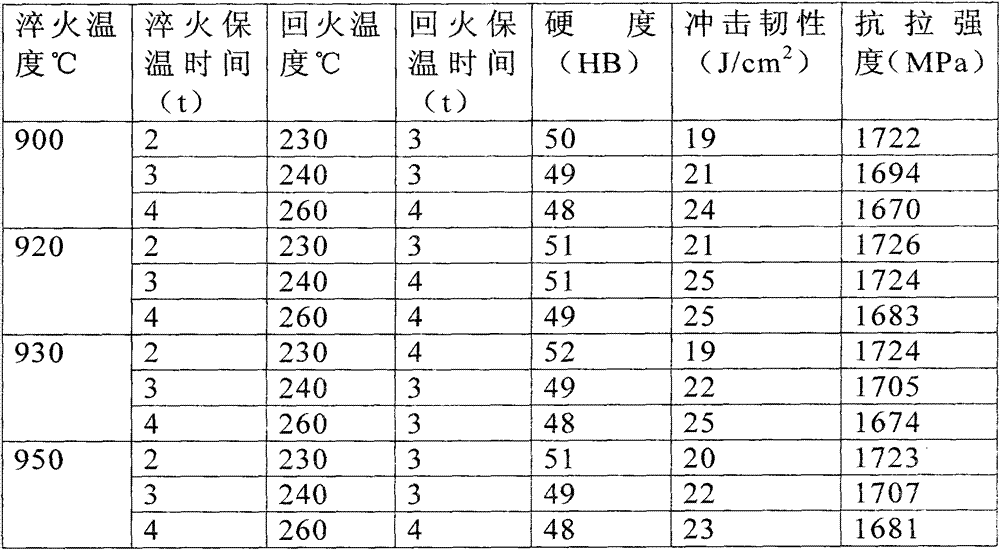

[0043] Table 4: Mechanical properties of excavator bucket teeth after heat treatment under different conditions in Example 3

[0044]

[0045]

[0046] From the above test, after adopting the proportioning of this embodiment, the excavator manufactured by using the process conditions of embodiment 1 has g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com