Novel composite probiotic preparation for pig-raising fermentation bed

A compound probiotic and fermentation bed technology, applied in the direction of bacteria, microorganisms, fungi, etc., can solve the problems of increasing the cost of raising pigs in the fermentation bed, affecting the economic benefits of breeding, and limited sawdust resources, so as to maintain the population advantage and improve Digestion and metabolism, improve the effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

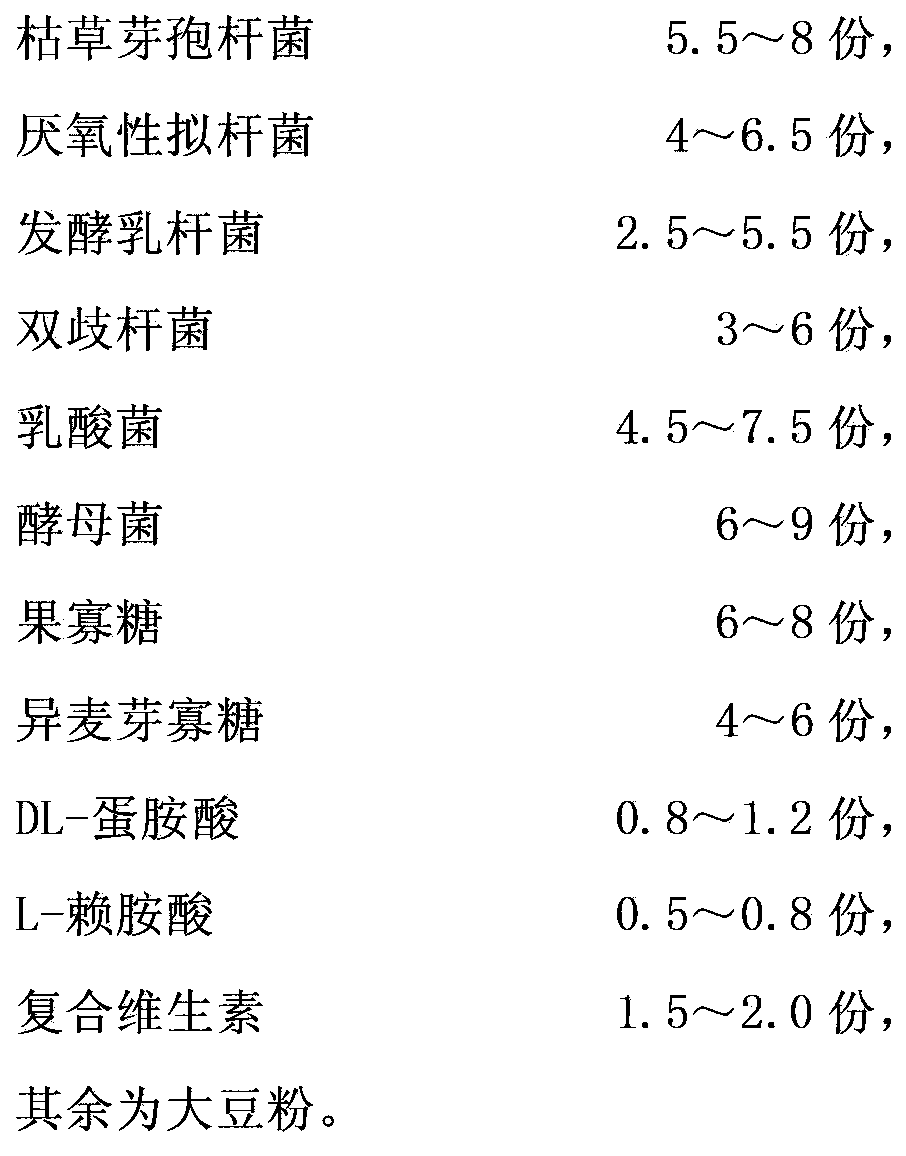

[0028] This embodiment relates to a novel fermented bed pig-raising composite probiotic preparation. The composite probiotic preparation includes the following components: 5.5 parts of Bacillus subtilis, anaerobic pseudo 6.5 parts of bacillus, 2.5 parts of Lactobacillus fermentum, 6 parts of bifidobacterium, 4.5 parts of lactic acid bacteria, 6 parts of yeast, 6 parts of fructooligosaccharide, 6 parts of isomaltooligosaccharide, 0.8 part of DL-methionine, L-lysamine 0.5 parts of acid, 1.5 parts of multivitamins, and the balance is soybean powder.

[0029] This embodiment also relates to the preparation method of the aforementioned novel fermented bed pig-raising compound probiotic preparation, the method comprising the following steps:

[0030] Configure 100 parts by weight of the new fermented bed pig-raising compound probiotic preparation: get 5.5 parts of Bacillus subtilis, 6.5 parts of anaerobic Bacteroides, 2.5 parts of Lactobacillus fermentum, 6 parts of Bifidobacteria, ...

Embodiment 2

[0032] This example relates to a novel fermented bed pig-raising compound probiotic preparation. The compound probiotic preparation includes the following components: 8 parts of Bacillus subtilis, anaerobic pseudo 4 parts of bacillus, 5.5 parts of Lactobacillus fermentum, 3 parts of bifidobacterium, 7.5 parts of lactic acid bacteria, 7.5 parts of yeast, 8 parts of fructooligosaccharide, 4 parts of isomaltooligosaccharide, 1.2 parts of DL-methionine, L-lysamine 0.8 parts of acid, 2.0 parts of multivitamins, and the balance is soybean powder.

[0033] This embodiment also relates to the preparation method of the aforementioned novel fermented bed pig-raising compound probiotic preparation, the method comprising the following steps:

[0034]Configure 100 parts by weight of the new fermented bed pig-raising compound probiotic preparation, weigh 8 parts of Bacillus subtilis, 4 parts of anaerobic Bacteroides, 5.5 parts of Lactobacillus fermentum, 3 parts of Bifidobacterium, 7.5 part...

Embodiment 3

[0036] This example relates to a novel fermented bed pig-raising composite probiotic preparation, which includes the following components: 100 parts by weight of the composite probiotic preparation, 6 parts of Bacillus subtilis, anaerobic pseudo 5.5 parts of Bacillus, 4.5 parts of Lactobacillus fermentum, 5 parts of Bifidobacterium, 6.5 parts of lactic acid bacteria, 9 parts of yeast, 7 parts of fructooligosaccharide, 5 parts of isomaltooligosaccharide, 1.0 part of DL-methionine, L-lysamine 0.6 parts of acid, 1.8 parts of multivitamins, and the balance is soybean powder.

[0037] This embodiment also relates to the preparation method of the aforementioned novel fermented bed pig-raising compound probiotic preparation, said method comprising the following steps:

[0038] Configure 100 parts by weight of the new fermented bed pig-raising compound probiotic preparation, weigh 6 parts of Bacillus subtilis, 5.5 parts of anaerobic Bacteroides, 4.5 parts of Lactobacillus fermentum, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com