Method for skin stretch-forming and locating with flexible multipoint mould

A multi-point mold and skinning technology, applied in the field of skinning, can solve the problems of poor positioning accuracy and difficult positioning, and achieve the effect of reducing manual errors and improving positioning accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

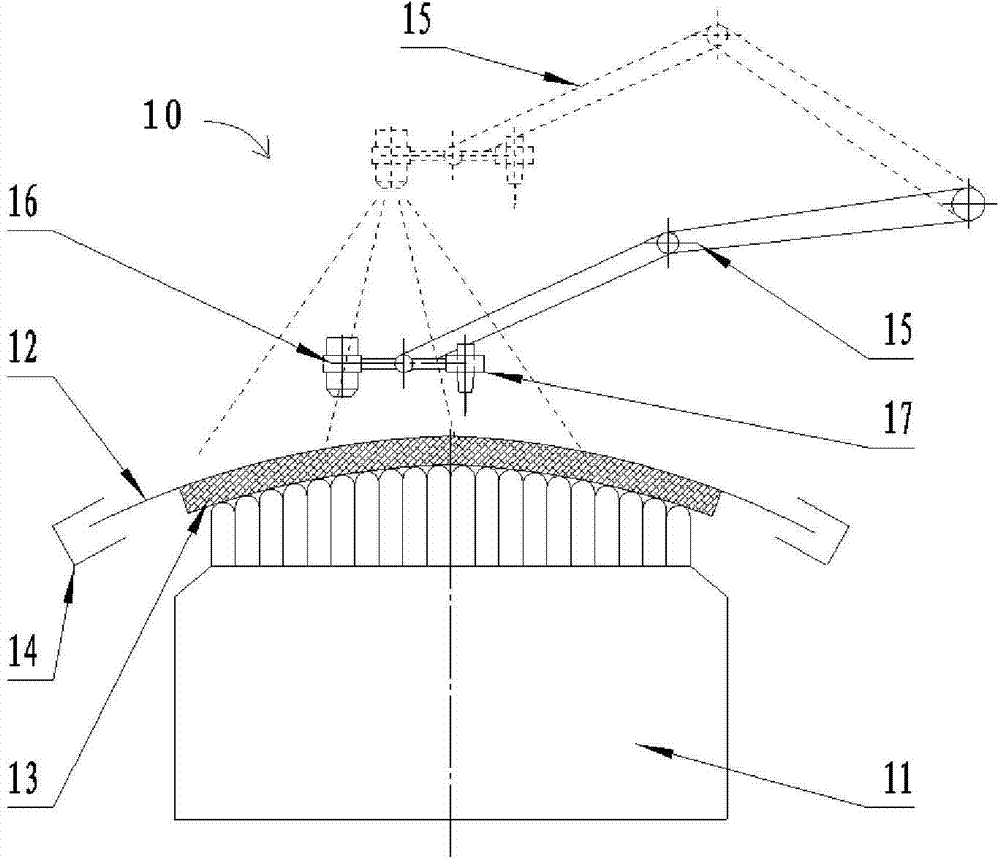

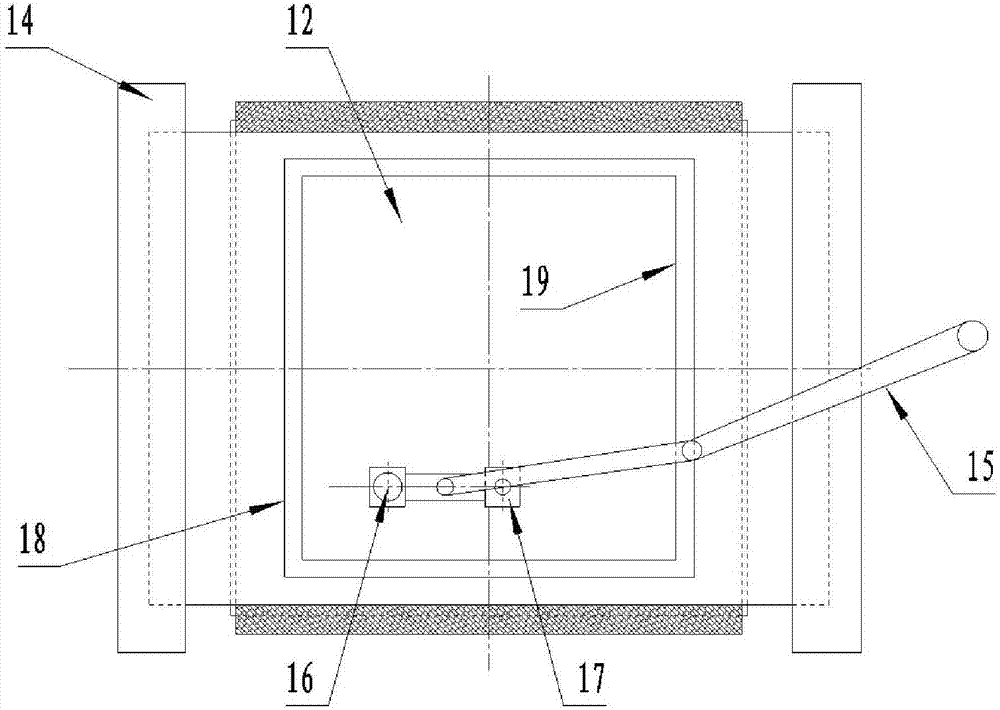

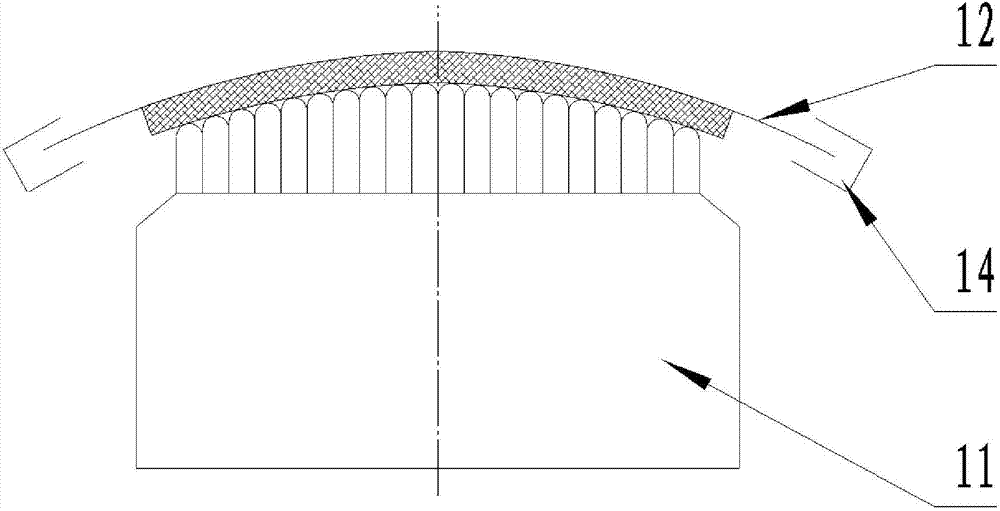

[0033] The method for skin stretching and positioning using a flexible multi-point mold according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] First introduce the flexible multi-point mold skin stretching device used in the method of adopting a flexible multi-point mold for skin stretching and positioning, including a multi-point mold 11, which contains a plurality of punches 115, each The heights of the tops of each punch 115 can be adjusted individually, and the skin pulling device of the flexible multi-point mold transition profile also includes a mechanical arm 15 and a clamp 14 for clamping and stretching the skin 12, mechanically One end of the arm 15 is provided with a measuring device 16 and a hole marking actuator 17, and the other end of the mechanical arm 15 can be fixed to a wall or a frame or a beam, such as figure 1 with figure 2 As shown, the device can complete the stretching, posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com