A wire fitting crimping tube plastic part

A technology of crimping tubes and fittings, which is applied in the field of wire crimping technology, which can solve the problems of large torque between the wire and the crimping tube, large wire diameter, and increase, and achieves the effect of simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

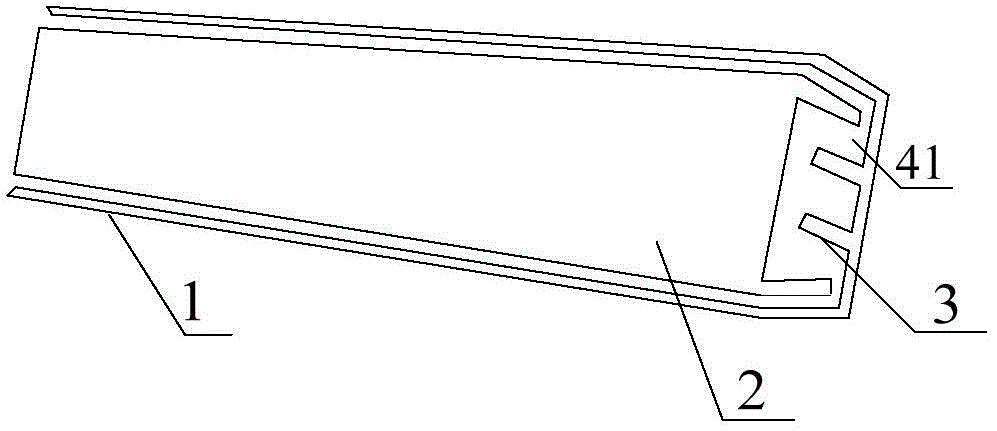

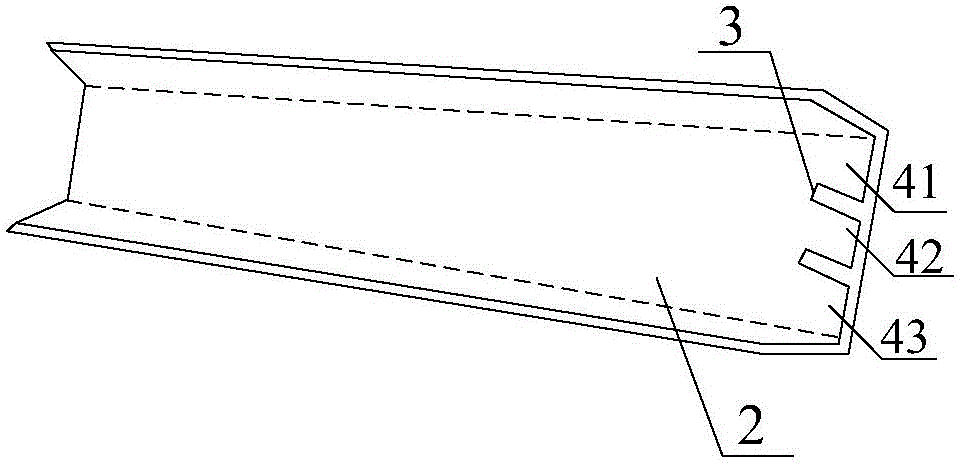

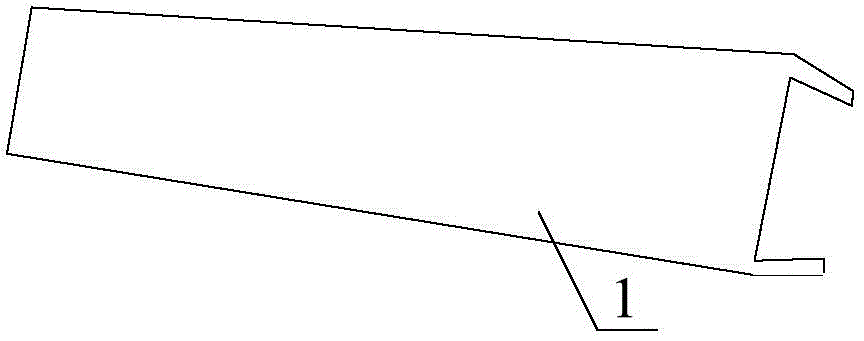

[0015] Such as Figure 1-3 As shown, a wire fitting crimping tube shaping part is characterized in that it includes an upper channel steel 1 and a lower channel steel 2 that are matched and lap-welded up and down, and the lower channel steel 2 is provided with two reinforcing ribs 3. The lower channel steel 2 is a U-shaped channel steel with an upward opening, and the two reinforcing ribs 3 are vertically welded on the lower channel steel 2, and form a first notch 41 and a second notch 41 with the lower channel steel 2 sides respectively. Three notches 43, the two reinforcing ribs 3 also form a second notch 42 with the bottom plate of the lower channel steel 2; the upper channel steel 1 is a U-shaped channel steel with the opening facing downward, and the upper channel steel Both sides of the steel 1 are snapped into the first notch 41 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com