Double-bundled-conductor hoisting frame with idler wheels

A double-split wire, lifting frame technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of incorrect and convenient installation of pulleys, time-consuming, wire danger, etc., and achieves convenient wire lifting, flexible and convenient use, and avoidance of work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

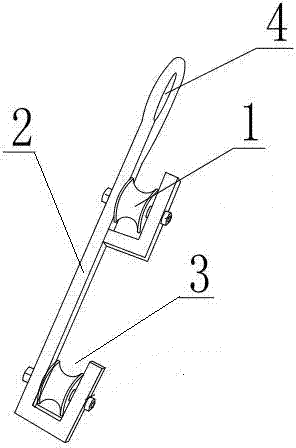

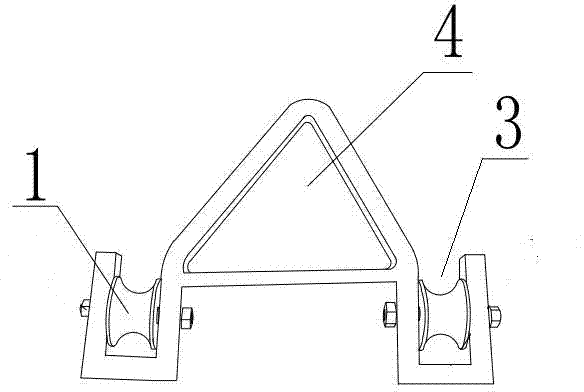

[0015] Example 2 as figure 2 A double-split wire lifting frame with rollers is shown, including a lifting frame body, which is provided with a hanging ring or a hook 4, and two rollers 1, which are arranged left and right, and the two rollers 1 The axes are perpendicular to the wire. The body structure of the lifting frame is an isosceles triangle frame, and two bottom corners of the isosceles triangle frame are respectively provided with a U-shaped groove 3 in the outer sides of the two base angles. Or the hook 4 is the isosceles triangle frame itself. The roller 1 is a grooved wheel. The material of the roller 1 is aluminum alloy. During use, the left and right wires are carried on the left and right rollers 1 respectively, and the purpose of lifting the wires is achieved by lifting the hanging ring or the hook 4 .

[0016] The beneficial effect produced by adopting the above-mentioned technical scheme is that: the double-split wire lifting frame with rollers makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com