Automatic change-over switch for two power sources

An automatic transfer switch and dual power supply technology, applied in electrical switches, circuits, electrical components, etc., can solve the problems of complex and clumsy push-pendulum components, stuck actuators, and high use costs, and prevent line aging or assembly errors. The effect of compact structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

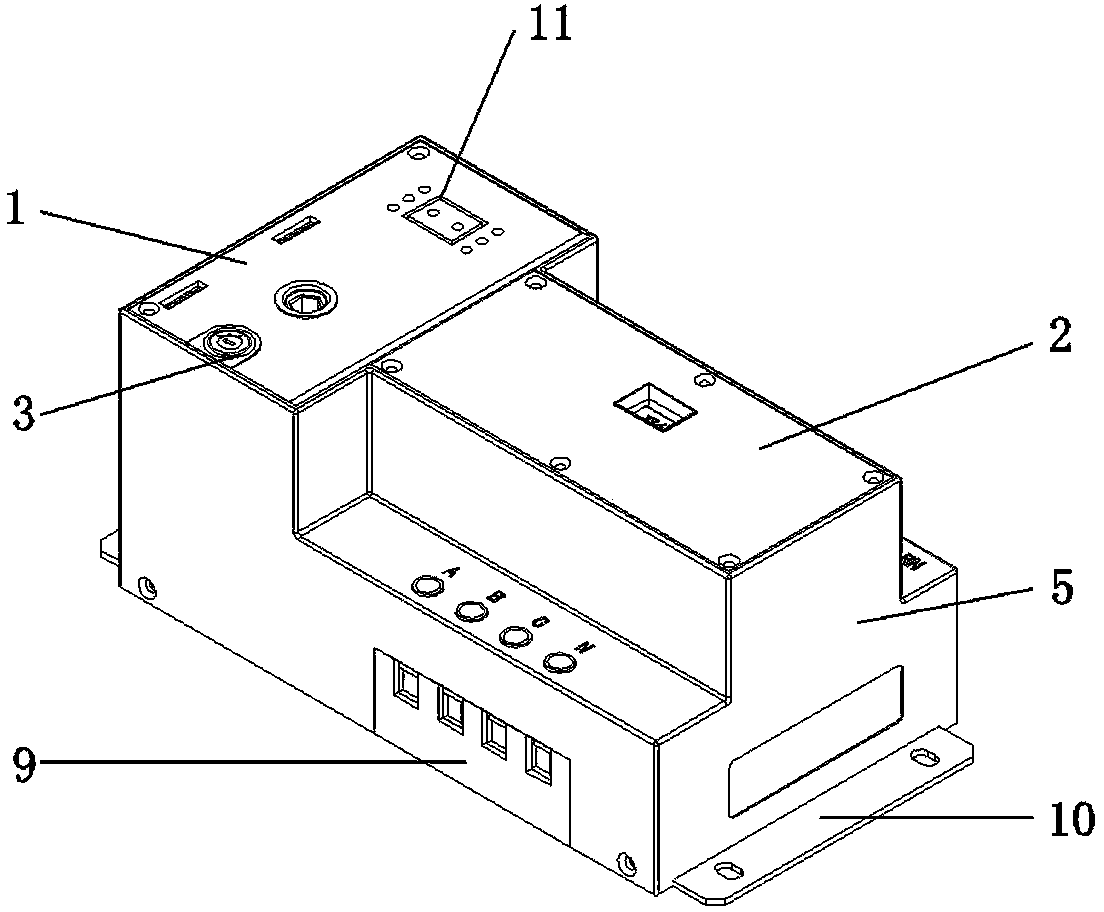

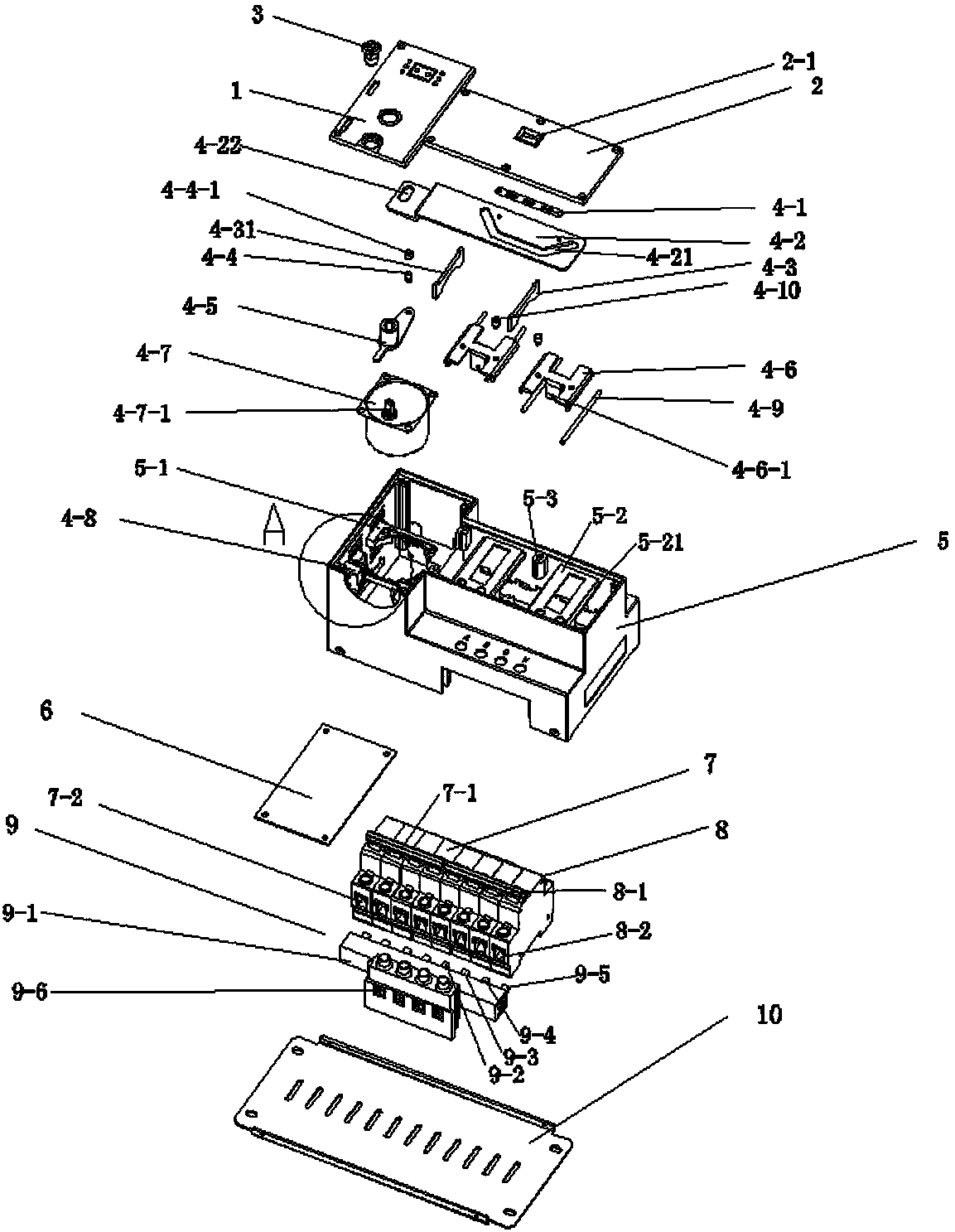

[0034]As shown in Figures 1 to 17, the dual-power automatic transfer switch includes a control circuit board 6, a main circuit breaker 7, a backup circuit breaker 8, a controller cover 1, and a circuit breaker with a closing position indication window 2-1 Cover 2, isolation electric lock 3, actuator, installation base 5, bus bar device 9, installation base plate 10.

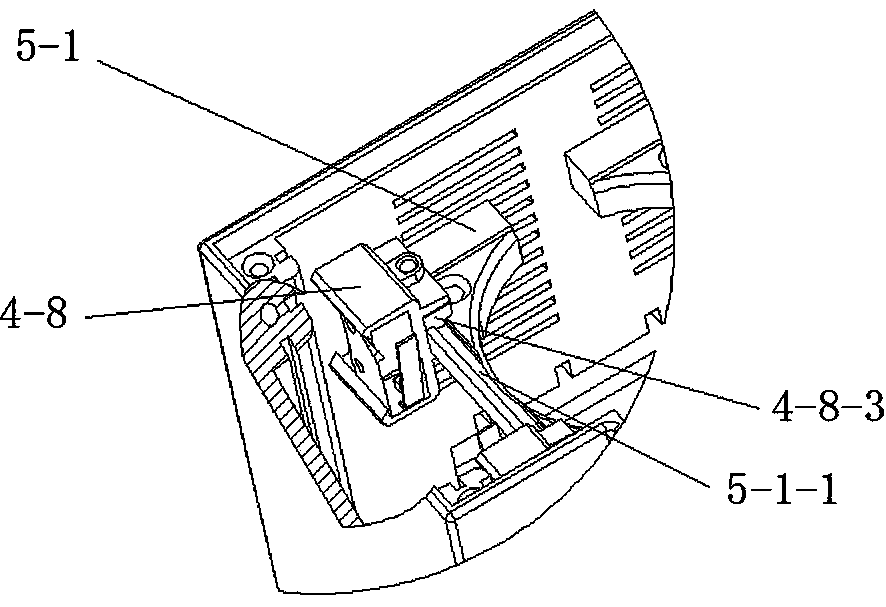

[0035] Drive turntable 4-5 comprises turntable core 4-5-1, turntable shaft 4-5-2, turntable core 4-5-1 is a tubular body, one end center hole is hexagonal hole 4-5-13, the other end center hole It is a rectangular hole 4-5-11 with both ends being arc-shaped, and four arc-shaped protrusions 4-5-12 are arranged at intervals on the end surface of the tube wall at one end of the turntable core 4-5-1; the turntable shaft 4- 5-2 One end is a conical plate-shaped body, the other end is a rectangular pendulum 4-5-21 with an arc-shaped head, and an instrument hole 4-5-22 and one and four The petal holes 4-5-23 matched by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com