Method for calculating steam admission enthalpy of air-cooling condenser of direct air-cooling unit

A technology of air-cooled condensers and air-cooled units, which is applied to the testing of machines/structural components, instruments, and measuring devices, and can solve problems affecting the accuracy of condenser performance calculation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention is described in detail below in conjunction with accompanying drawing:

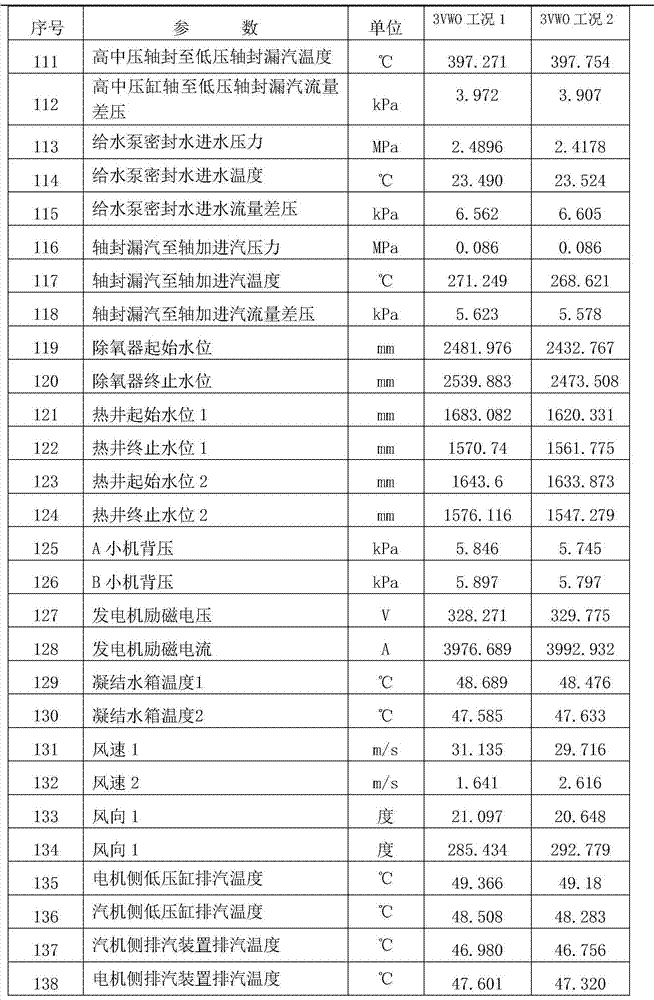

[0075] figure 1 It is a layout diagram of the measuring points of the thermal system of the steam turbine unit. The calculation method of the inlet steam enthalpy of the air-cooled condenser of the direct air-cooled unit includes the following steps:

[0076] Step 1: Measure the flow of condensed water entering the deaerator, the leakage steam flow of the front and rear shaft seals of the high and medium pressure cylinders, the steam intake flow of the shaft seal of the low pressure cylinder, the leakage flow of the steam inlet valve stem of the high and medium pressure cylinders, and the flow of steam entering the supply The sealing water flow rate of the water pump;

[0077] Step 2: According to the energy balance and mass balance of the high-pressure heater and deaerator, calculate the extraction steam flow, feed water flow, main steam flow, high-pressure cylinder exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com