Testing system for internal temperature distribution in process of fusion cast forming of explosives

A technology of melting and casting, internal temperature, applied in thermometers, thermometers with physical/chemical changes, measuring devices, etc., can solve the problems of single temperature signal perception and measurement, achieve continuous temperature measurement, strong anti-interference ability, temperature small field effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

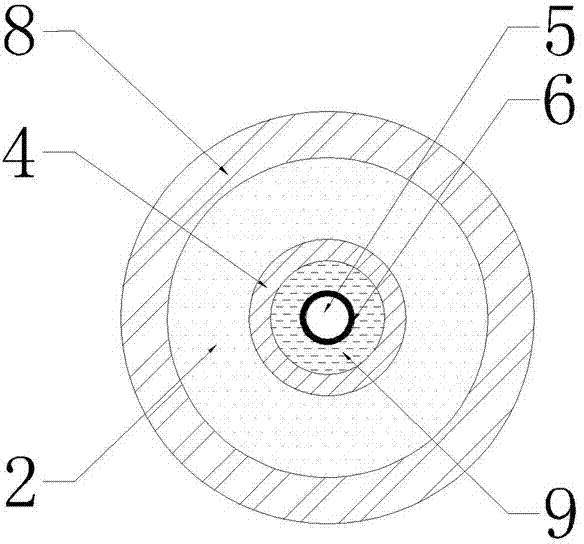

[0032] The internal temperature distribution testing system of the explosive melting and casting molding process involved in the present invention is divided into four parts: an optical fiber Bragg grating sensor array 10 , a signal detection and demodulation device 30 , a service and monitoring device 40 and an explosive melting and casting device 20 . The overall structure of the system is as Image 6 .

[0033] The explosive melting and casting device 20 is composed of a mold, a process cover, a thermal insulation riser and explosives in the mold, and its main function is to realize the melting and casting of explosives and place the fiber Bragg grating sensor array 10 to monitor the temperature. The fiber Bragg grating sensor array 10 consists of several grating sensor units connected in series by an optical fiber and arranged in an "S" shape to measure the temperature of multiple points in the explosive melting and casting device 20 and output optical signals. The signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com