A kind of self-lubricating system and self-lubricating method of seawater pump

A self-lubricating, seawater pump technology, applied to pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve the problem of affecting the work of the pump group, being easily blocked by dirt, and polluted water sources and other problems, achieve good backwashing effect, save external water resources, and achieve long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

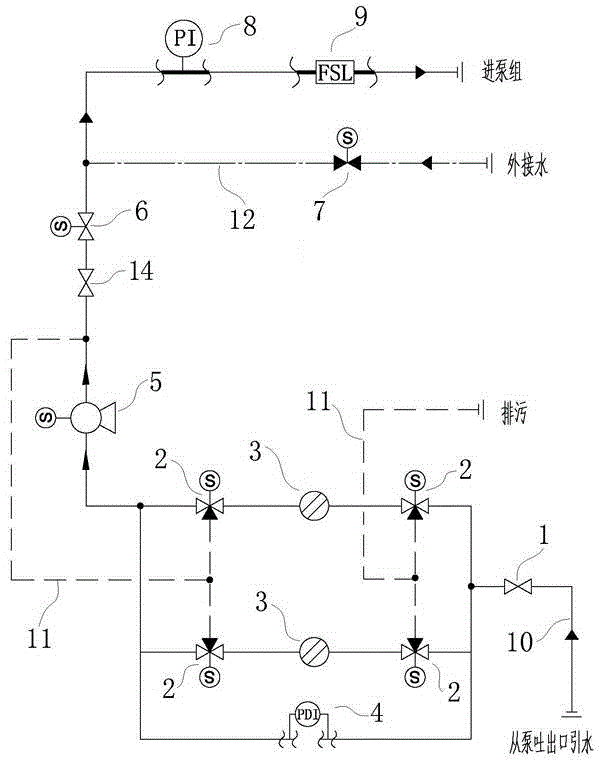

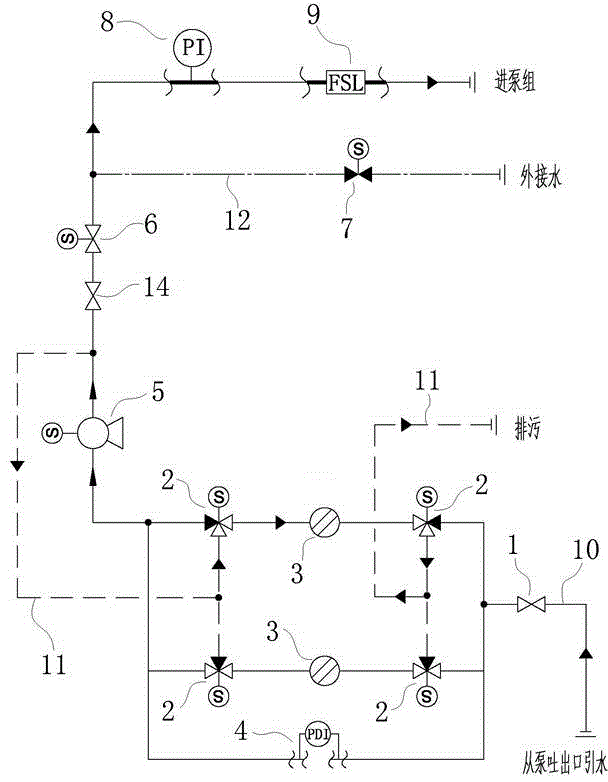

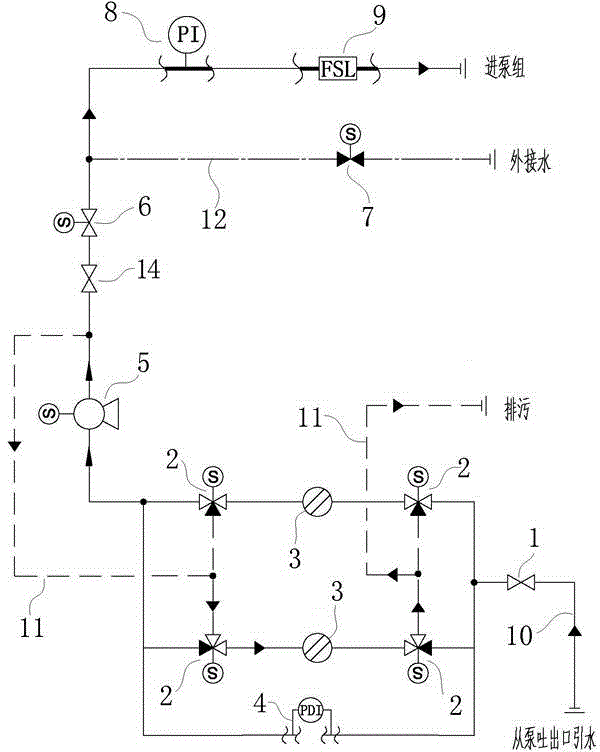

[0034] A seawater pump self-lubricating system, such as figure 1 As shown, the system includes gate valve 1, two-position three-way solenoid valve 2, laminated filter 3, differential pressure switch 4, booster pump 5, two-position two-way solenoid valve 6, 7, pressure transmitter 8, Flow switch 9 and each pipeline;

[0035] An embodiment of a seawater pump self-lubricating integrated device, the device is divided into three pipelines: a main pipeline 10, a backwash pipeline 11; an external water pipeline 12;

[0036] Such as figure 1 As shown, the connection of each pipeline and each component is as follows (in the backward order of the water flow direction):

[0037] The main pipe is connected to the discharge outlet of the pump group, and the gate valve is connected to it; two sets of parallel laminated filters are installed on the main pipe behind the gate valve, and a two-position three-way solenoid valve is installed on the front and rear pipelines of each set of lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com