Wedge type sound barrier

A sound barrier and wedge-type technology, applied in the field of wedge-type sound barriers, can solve problems such as sound barrier damage, sound insulation loopholes of the sound barrier, and noise pollution in the surrounding environment, and achieve reduced structural complexity, green energy, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

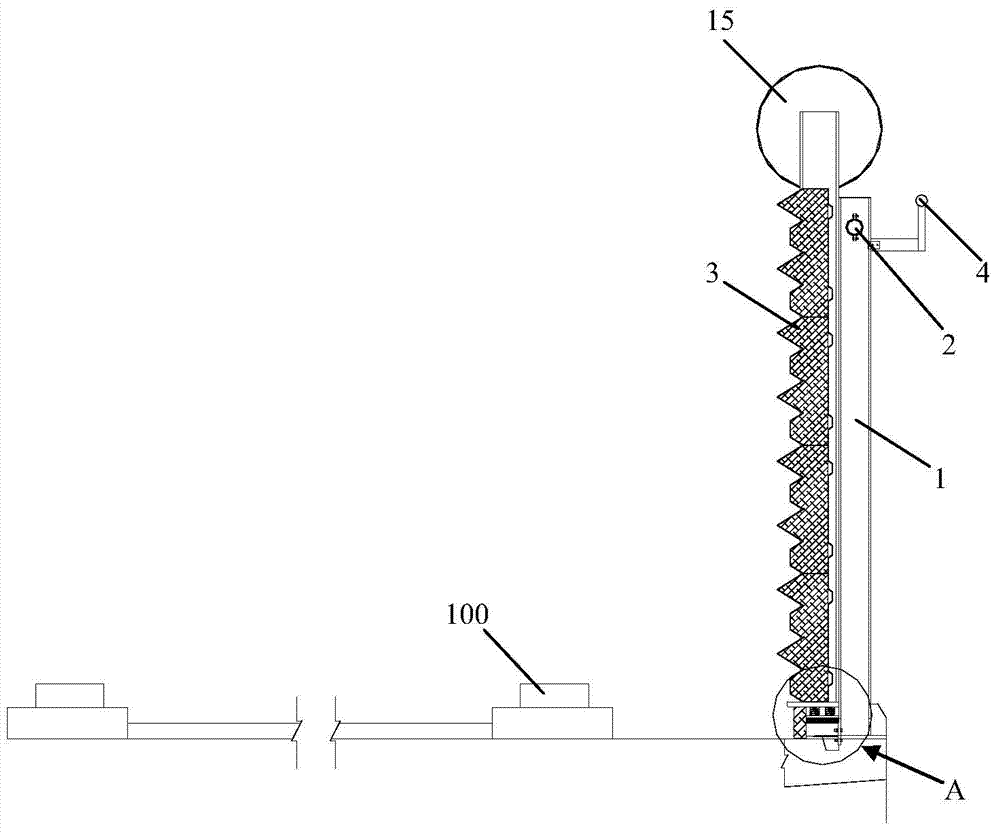

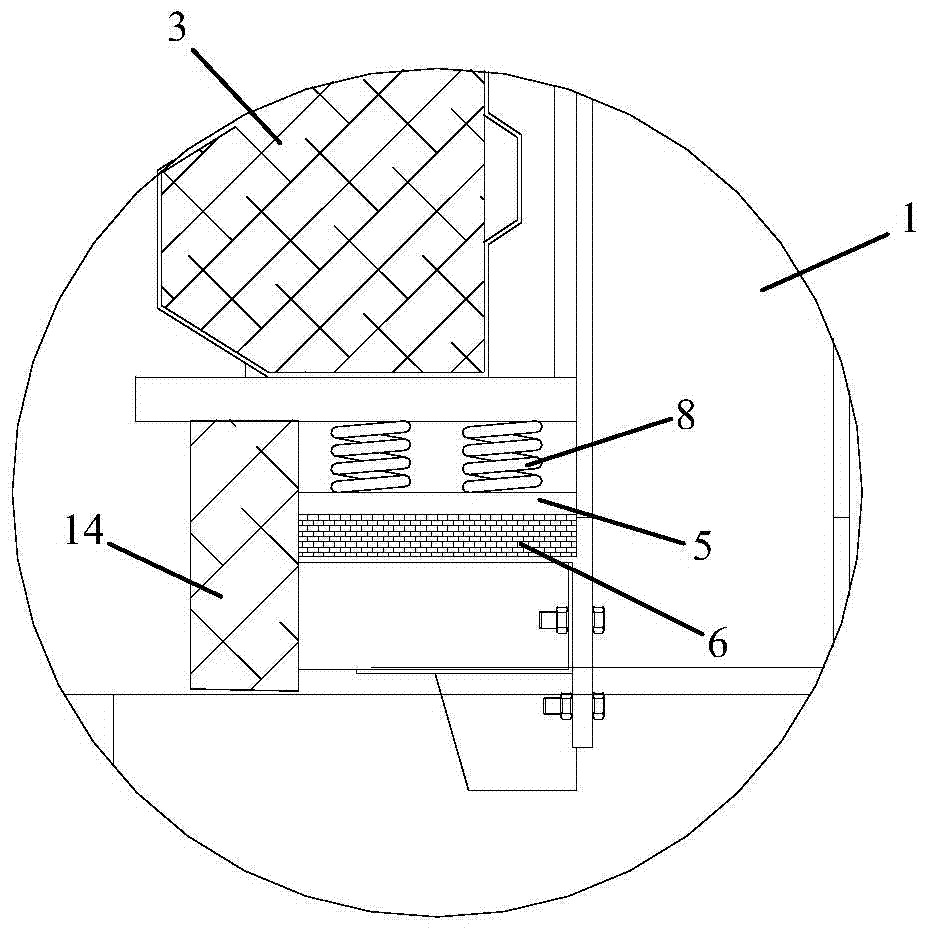

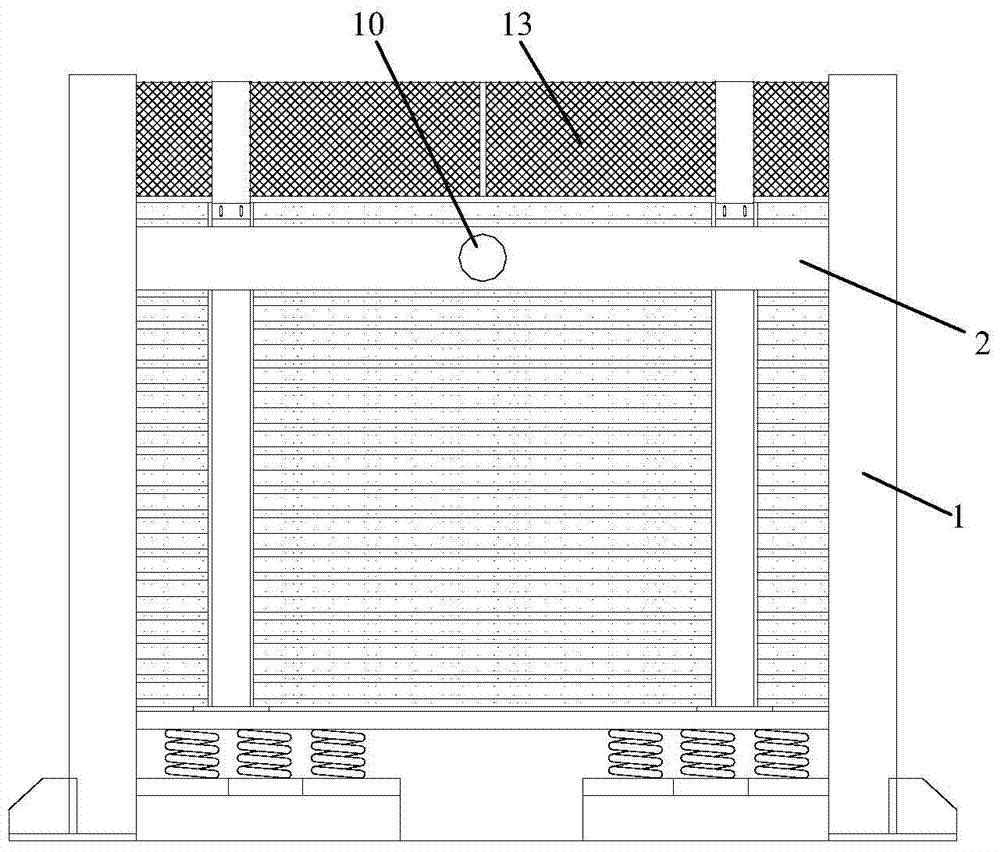

[0027] Such as figure 1 As shown, a wedge-shaped sound barrier of the present invention includes a plurality of steel columns 1 located on one side of the track 100, and adjacent steel columns 1 are connected and fixed by supporting beams 2; between the steel columns 1 A sound-absorbing wedge 3 is provided; a first sound-absorbing screen body 15 is arranged above the sound-absorbing wedge 3; a noise sensor 4 is arranged on the side of the sound-absorbing wedge 3 away from the track 100, and the noise sensor 4 and The control circuit is connected, and the control circuit is connected with the storage battery (not shown in the figure).

[0028] Such as Figure 7 As shown, the control circuit includes a signal acquisition module, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com