Clamping device for carrying barrel body

A clamping device and drum technology, applied in the field of clamping devices, can solve the problems of increased operating costs, insufficient reliability, and inability to carry heavy drums, etc., and achieve the effect of easy clamping operation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

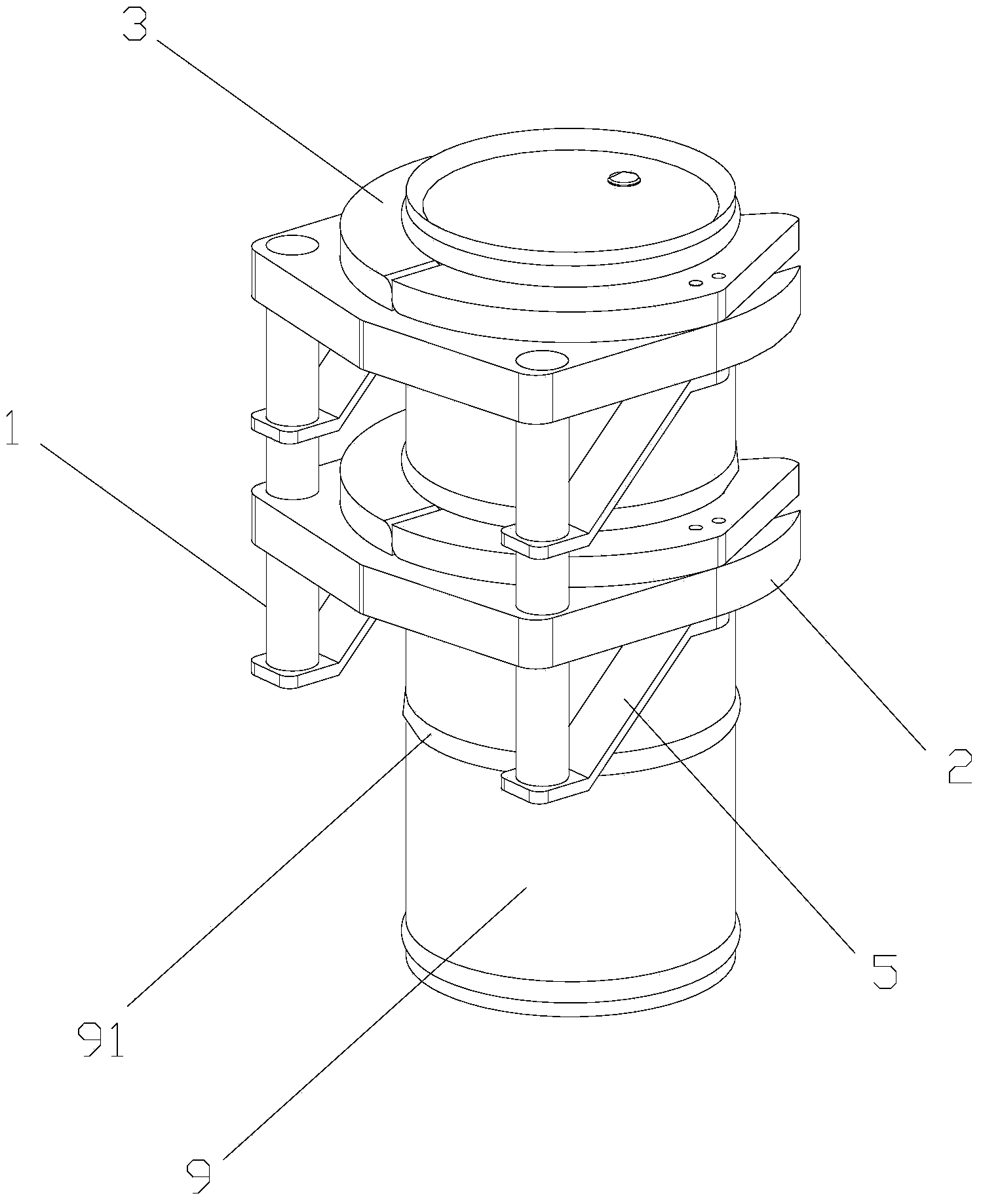

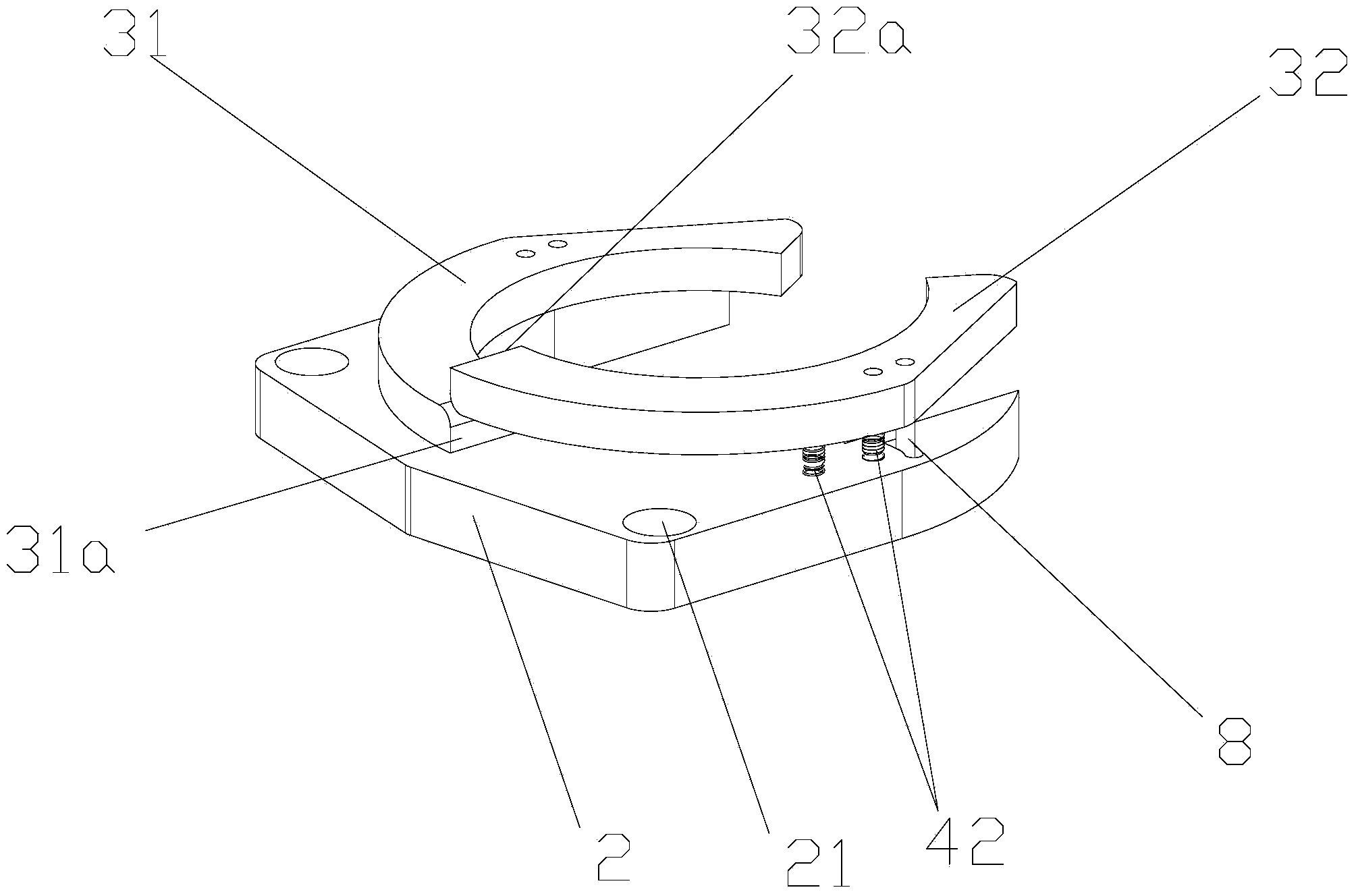

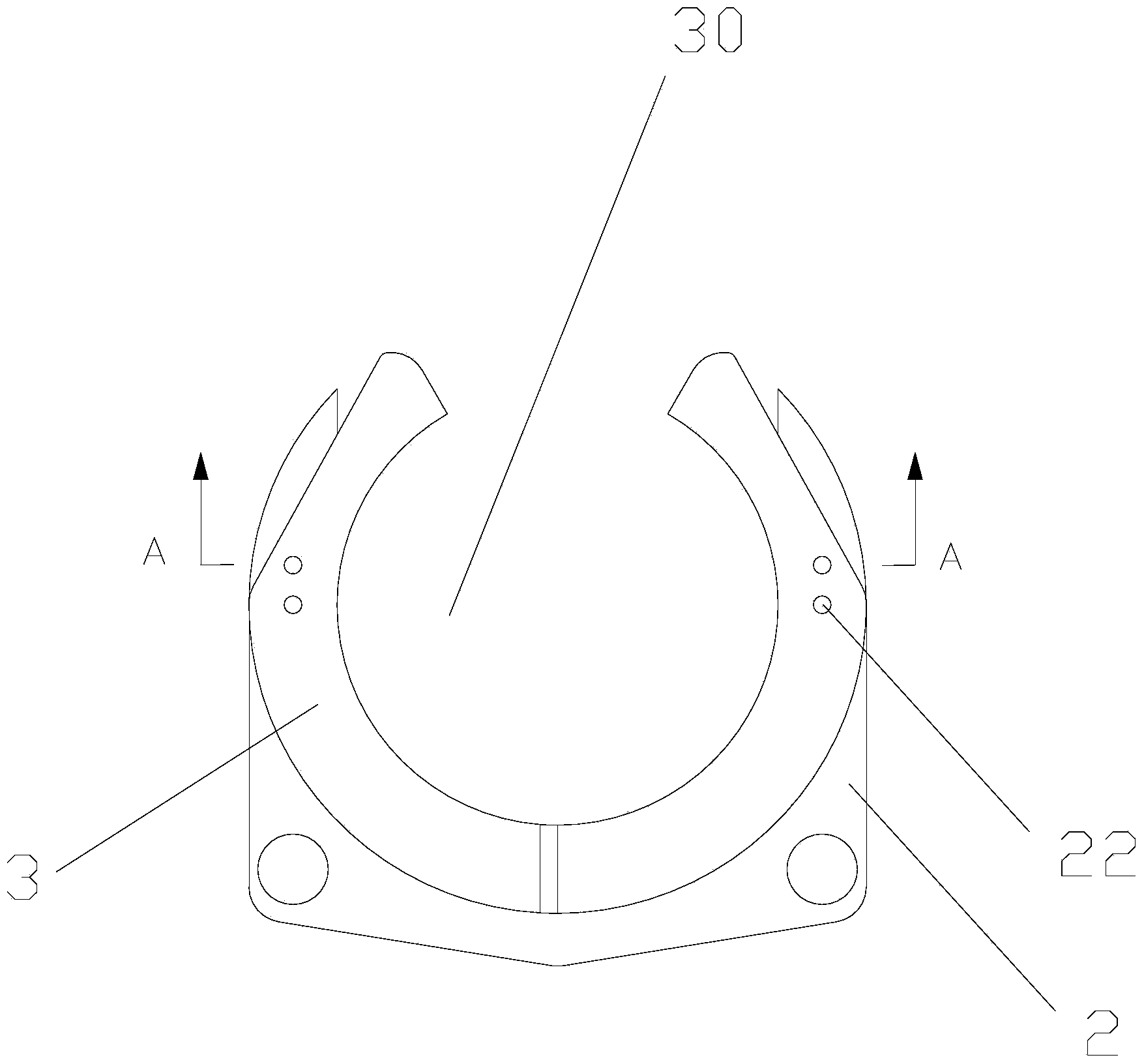

[0022] figure 1 It is a structural representation of the present invention, figure 2 It is a structural schematic diagram of the clamping mechanism of the present invention, image 3 It is a top view of the clamping mechanism of the present invention, Figure 4 for image 3 A-A sectional view of, Figure 5 It is a structural schematic diagram of the clamping plate of the present invention, as shown in the figure: the clamping device for handling the drum body of the present invention includes at least two supporting columns 1 arranged in parallel and at least one group fixed on the supporting columns 1 The clamping mechanism includes a clamping plate 2 and an arc-shaped mouth 30 that is connected to the clamping plate 2 and has a shape that matches the shape of the outer surface of the cylinder body 9, and is used to hold and clamp the circle. The clamping claw 3 on the outer wall of the barrel body 9, the clamping plate 2 has a gap 20 for the entry of the barrel body 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com