Three-work-station dual-ground-connection load switch

A technology of load switch and double grounding, applied in the direction of air switch components, electrical components, etc., can solve the problem of not reducing the workload of overhauling high-voltage fuses, and achieve the effect of improving safety and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

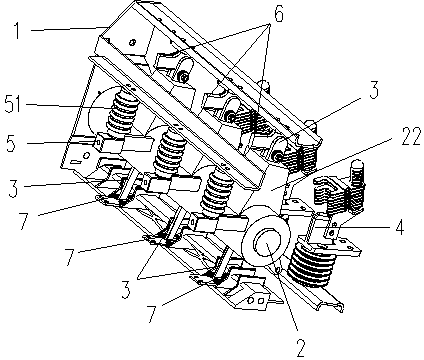

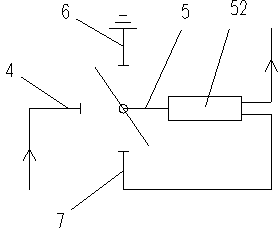

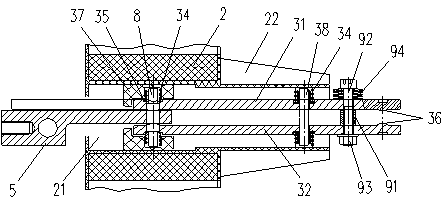

[0033] see Figure 1-2 , the three-position double-ground load switch of the present invention includes a bracket 1; an insulating main shaft 2, and the two ends of the insulating main shaft 2 are installed in the shaft holes on the two side plates of the bracket 1, and the insulating main shaft 2 is configured by The driving mechanism at one end drives the rotation, and the driving mechanism in this embodiment adopts a traditional spring operating mechanism, see Figure 9-10, the corresponding end of the insulating main shaft is provided with a spline hole, and the insulating main shaft is matched with the spring operating mechanism through a spline. The insulating main shaft 2 is provided with a plurality of radially extending contact blades 3, and when the contact blades 3 rotate to the on position with the insulating main shaft 2, they conduct the upper static contact seat 4 and the square conductor 5; The contact seat 4 is connected to the input cable, and a high-voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com