Method for testing actual flow characteristics of steam turbine valve

A technology of actual flow and characteristic testing, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as inaccurate testing of actual flow characteristics, achieve good direct economic benefits, and improve safe and economical operation Level and power quality, and the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

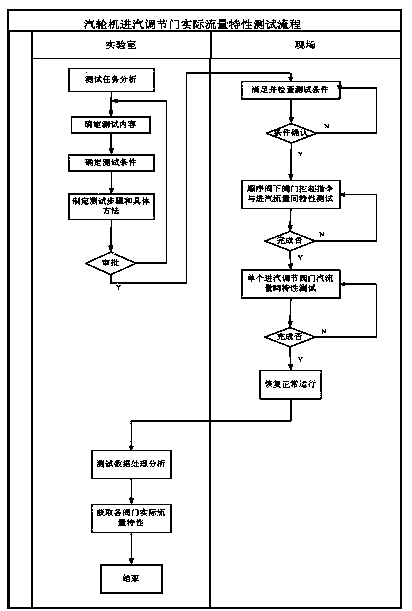

[0014] Embodiment of the present invention: a method for testing the actual flow characteristics of a steam turbine valve, which includes determining the test content, test conditions, test steps and specific methods, and carrying out the test work.

[0015] The test content includes two aspects: ① The steam inlet regulating valve of the steam turbine is in the sequence valve working mode (referring to multiple steam inlet regulating valves according to the preset program, under the action of the valve control command, the switching action is performed in sequence to adjust the inlet and outlet valves. Steam volume, this working method is economical and is the main operation method used by steam turbines), change the valve control command, and test the characteristic relationship between the valve control command and the inlet steam flow. ②Keep the other steam inlet regulating valves fully open, switch on and off the individual steam inlet regulating doors one by one, and test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com