Sealing device for end parts of pipe

A technology of end sealing and pipe materials, which is applied in the direction of measuring devices, analyzing materials, liquid tightness measurement using liquid/vacuum degree, etc., can solve the impact of end sealing body sealing and loss, slow installation and test speed, and influence Product quality and other issues, to achieve the effect of fast installation, good sealing and fixing effect, and good connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

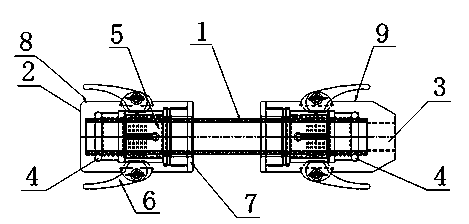

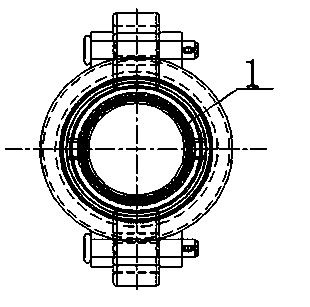

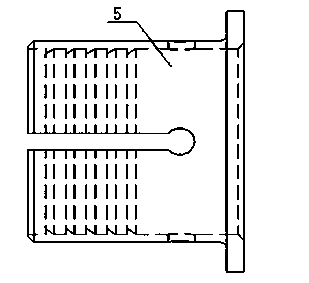

[0029] Such as figure 1 As shown, a pipe end sealing device includes a sealing end sealing body 2 and an air inlet sealing body 3 respectively installed on both ends of the pipe material 1, the sealing end sealing body 2 has an opening at one end, and the air inlet end sealing body 3 Both ends are open, the sealing body 2 at the sealing end and the sealing body 3 at the intake end are both hollow cavities inside, and a sealing ring 4 and a spring sleeve clamp 5 for the pipe 1 to pass through are installed in the hollow cavity, and the sealing body at the sealing end 2 and the outer side of the air inlet sealing body 3 is equipped with a clamping wrench 6 in contact with the spring sleeve clamp 5, and the clamping wrench 6 can squeeze the spring sleeve clamp 5 to deform and block the pipe passing through it 1. An end sealing head 7 is provided at one opening end of the sealing body 2 at the sealing end and the sealing body 3 at the intake end.

[0030] Wherein, the spring slee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com