Vibration damping tube support for vertical pipeline

A vertical pipeline and vibration damping tube technology, which is applied to chemical process pipelines and petrochemical fields, can solve problems such as hidden dangers of pipeline safety operation, and achieve the effects of reducing pipeline damage accidents, simple structure, and convenient manufacturing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

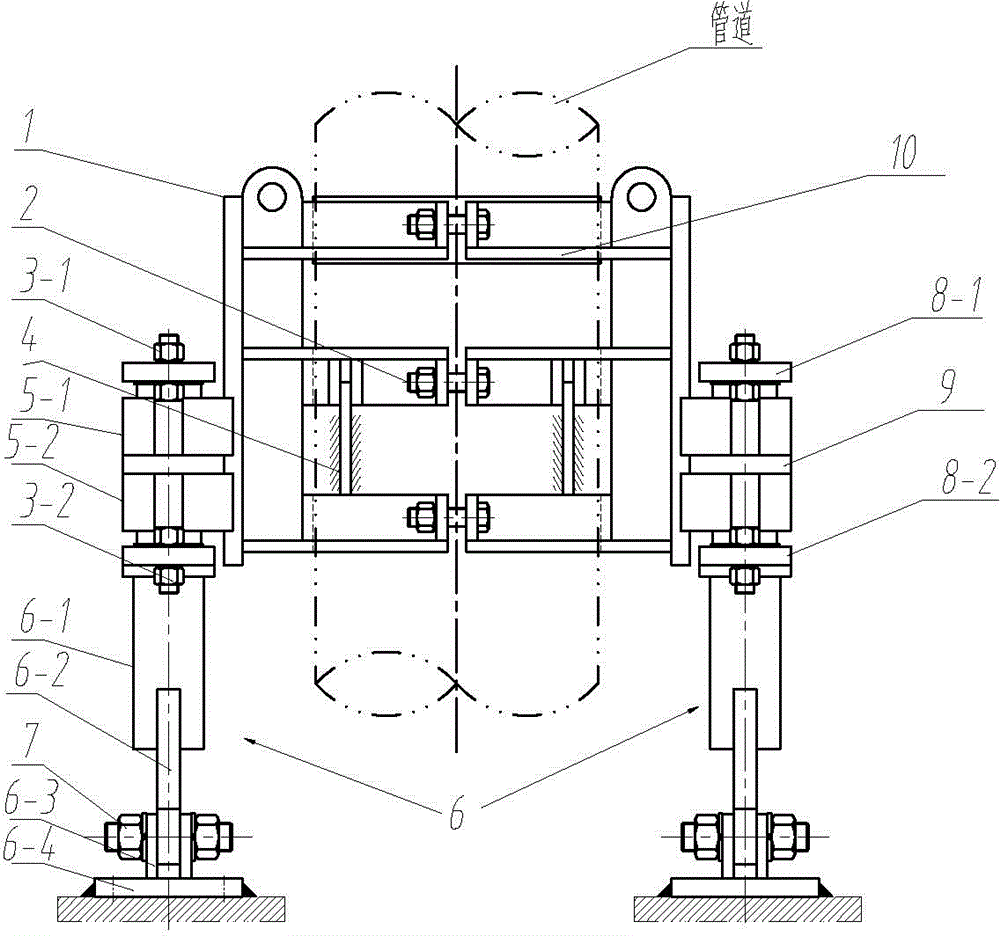

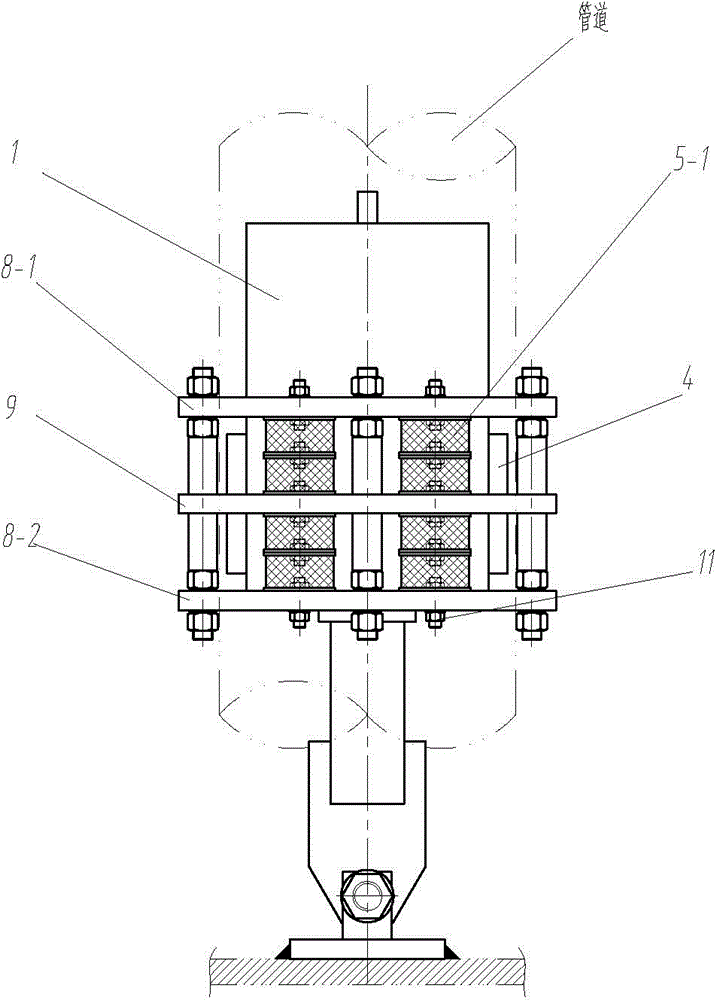

[0015] Such as Figure 1-2 shown.

[0016] A vibration damping pipe support for vertical pipelines, characterized in that it includes a pipe clamp 1, fastening bolts 2, an upper pull rod assembly 3-1, a lower pull rod assembly 3-2, a stopper 4, and an upper shock absorber pad 5- 1. Lower vibration damping pad 5-2, sliding outrigger 6, hinge shaft 7, upper backing plate 8-1, lower backing plate 8-2, fixing plate 9 and fastener 11, several groups of pipe clamps 1 are connected Clamping rings, each clamping ring is connected and tightly held on the vertical pipeline by fastening bolts 2, and the stopper 4 is welded on the vertical pipeline and protrudes between adjacent clamping rings to prevent the clamping rings from moving vertically. Sliding on the pipe; a fixed plate 9 is welded on both sides of the pipe clamp 1, each fixed plate 9 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com