Dual Clutch Transmission Transmission Mechanism

A technology of dual-clutch transmission and transmission mechanism, which is applied to the transmission device, gear transmission device, transmission device control, etc., can solve the problems that are unfavorable to the layout design of the car structure, the transmission ratio of the first gear is small, and the engine speed changes greatly. The effect of flexible structural layout design, reduced axial and radial dimensions, and small changes in engine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ( 8

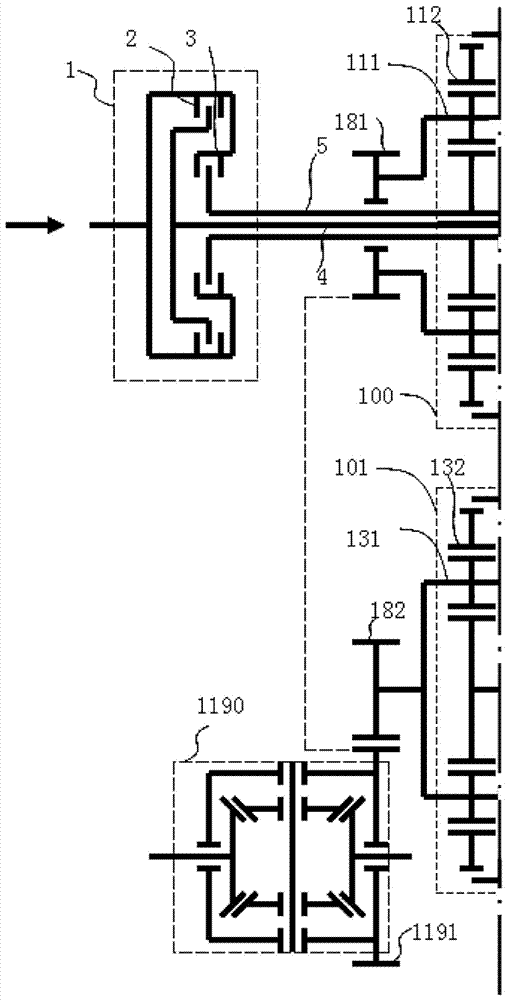

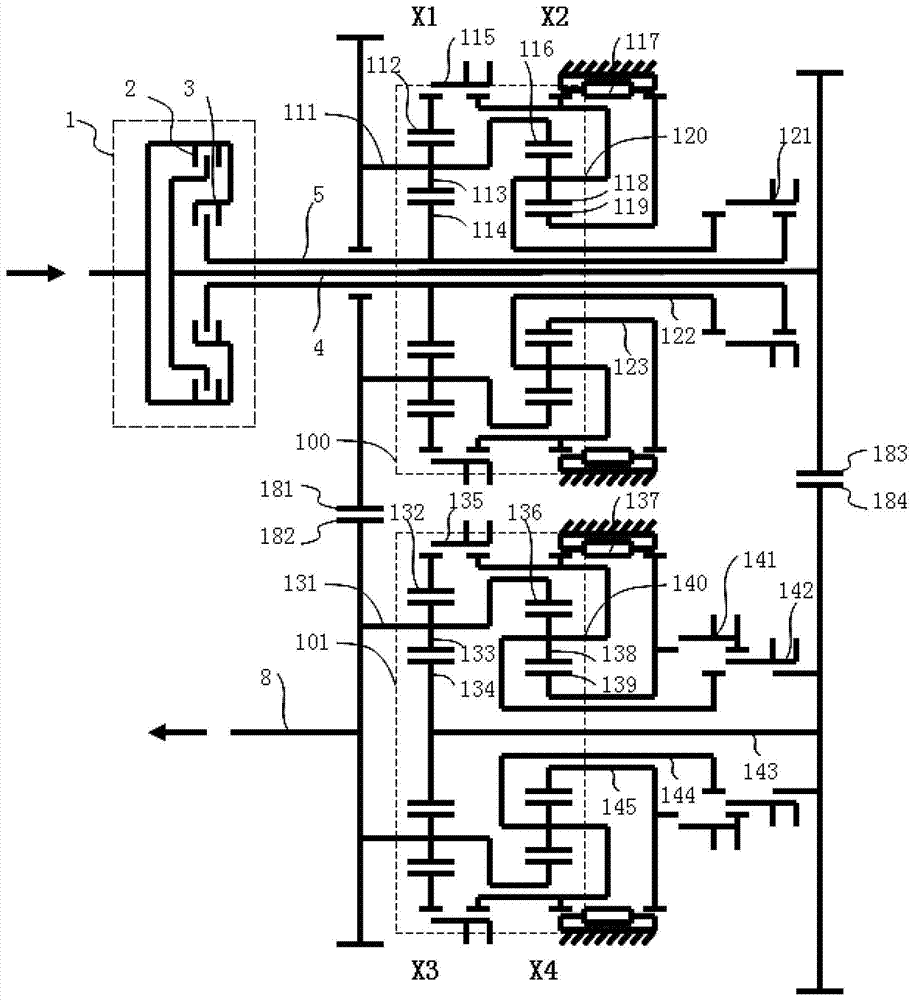

[0027] see figure 1 , the dual clutch of the present invention includes a dual clutch assembly 1 (comprising a first clutch 2 and a second clutch 3, a first input shaft 4 and a second input shaft 5 corresponding to the two clutches respectively, a first double-row planetary gear train 100, a second Two double-row planetary gear trains 101, an output shaft 130, and multiple synchronizers. The first double-row planetary gear train and the second double-row planetary gear train are arranged up and down, and both are CR-CR gear transmission mechanisms. The planetary gear system includes two planetary rows at the front and rear, the front planetary row is the first planetary row X1, the rear planetary row is the second planetary row X2, and the second double-row planetary gear system includes the third planetary row X3 (the second double-row planetary gear The front planetary row of the system) and the fourth planetary row X4 (the rear planetary row of the second double-row planeta...

no. 2 example ( 7

[0056] see figure 2 , on the basis of the first embodiment, the dual-clutch assembly 1 is arranged on the right side of the first double-row planetary gear train 100, and the output shaft 8 is arranged on the second double-row planetary gear train 101 on a different axis from the dual-clutch assembly 1 And not on the same side, cancel the sixth and eighth gear synchronizers 121 and the first intermediate bushing 122, and set the sixth gear synchronizer 124 between the second input shaft 5 and the rear sun gear 119 of the first planetary gear train. According to gear ratio settings, it is necessary to appropriately change the transmission ratios of the first gear 181 and the second gear 182, the third gear 183 and the fourth gear 184, and the gear ratios of each planetary row. value. The first double-row planetary gear train 100 realizes second, fourth and sixth gears like this, and the second double-row planetary gear train 101 realizes first, third, fifth, seventh and reve...

no. 3 example ( 6

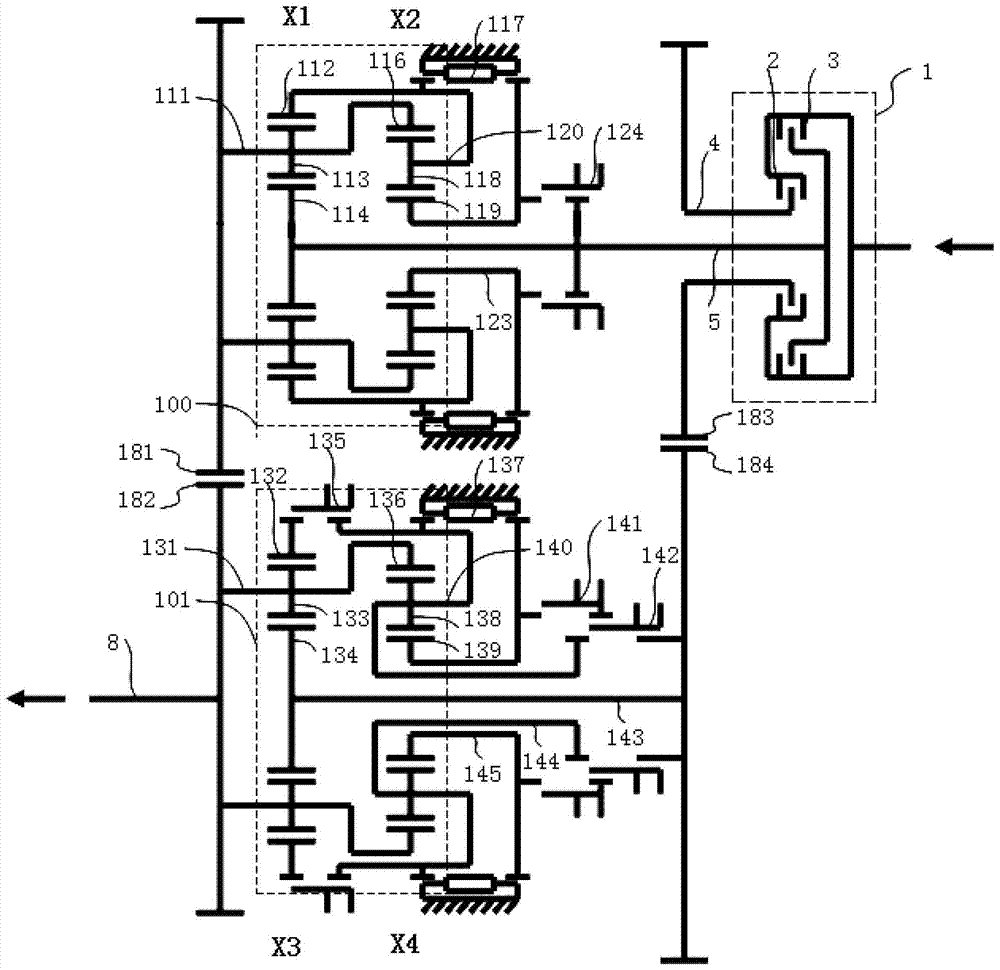

[0058] see image 3 , on the basis of the second embodiment, the output shaft 8 is arranged on the first double-row planetary gear train 100 on the same axis as the dual-clutch assembly 1 on different sides, and the second constant mesh synchronizer 135 and the reverse gear synchronizer are canceled 141 and fifth and seventh gear synchronizers 142, and a sixth gear synchronizer 146 is set between the rear sun gear 139 and the fourth gear 184 of the second planetary gear train. The first constant mesh synchronizer 115 in the first embodiment is recovered on the first double row planetary gear train 100 . In order to better meet the gear ratio setting requirements, the transmission ratios of the first gear 181 and the second gear 182, the third gear 183 and the fourth gear 184, and the gear ratios of each planetary row can be appropriately changed. value. The first double-row planetary gear train 100 realizes first, third, fifth and reverse gears, and the second double-row pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com