Bidirectional electromagnetic diaphragm pump

A diaphragm pump and electromagnetic technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machinery, etc., can solve the problems of small flow, large flow pulsation, and low pump efficiency of electromagnetic diaphragm pumps, and achieve continuous flow, High operating efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

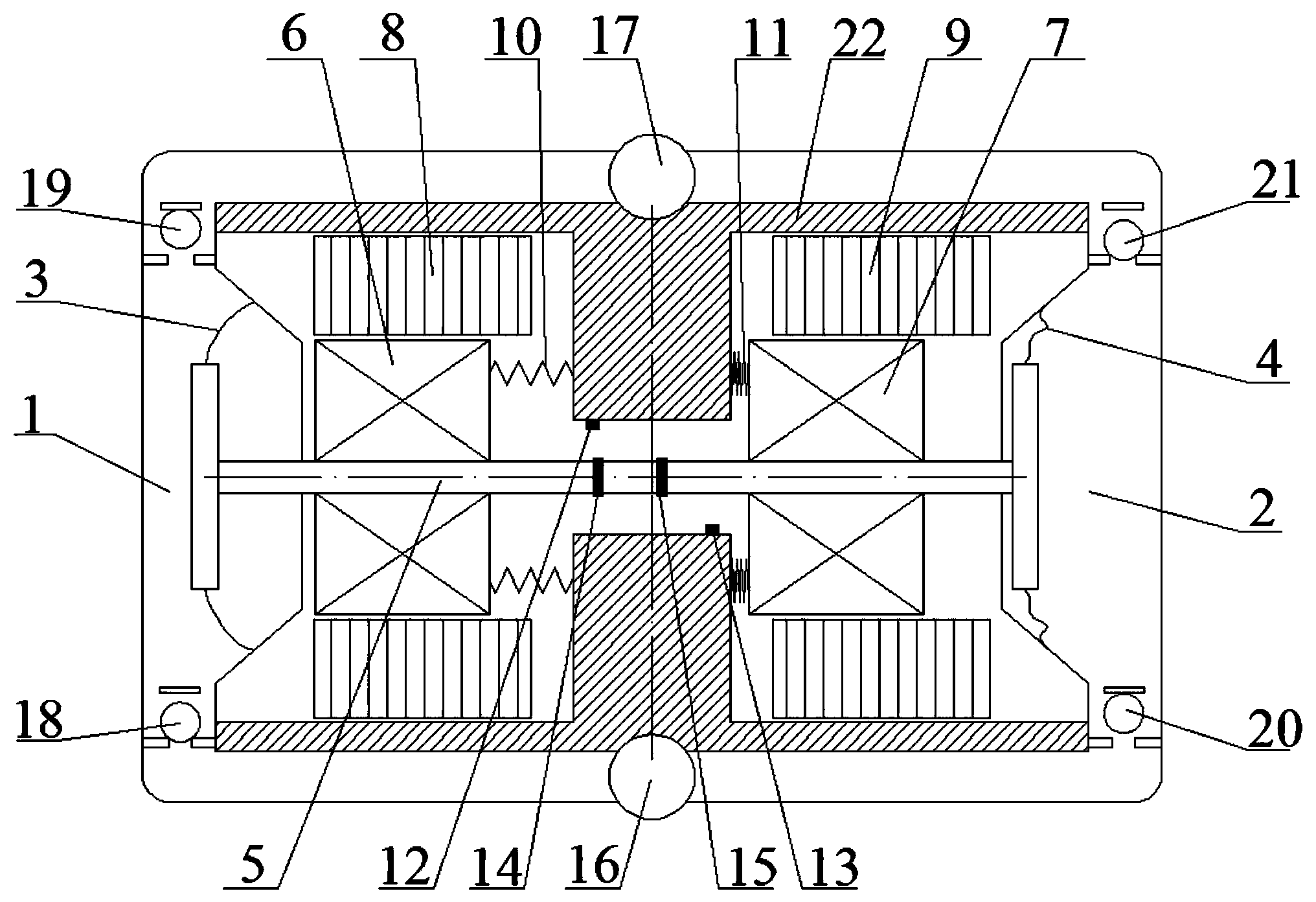

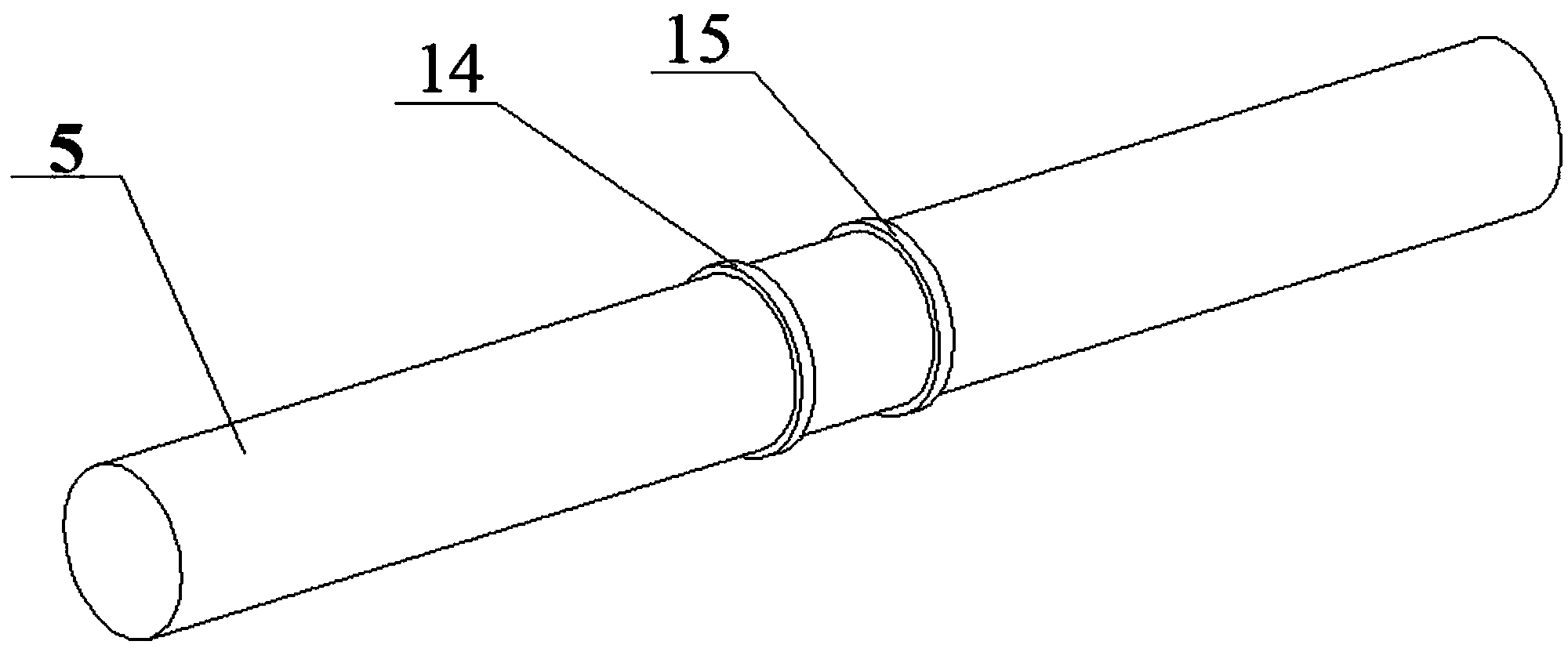

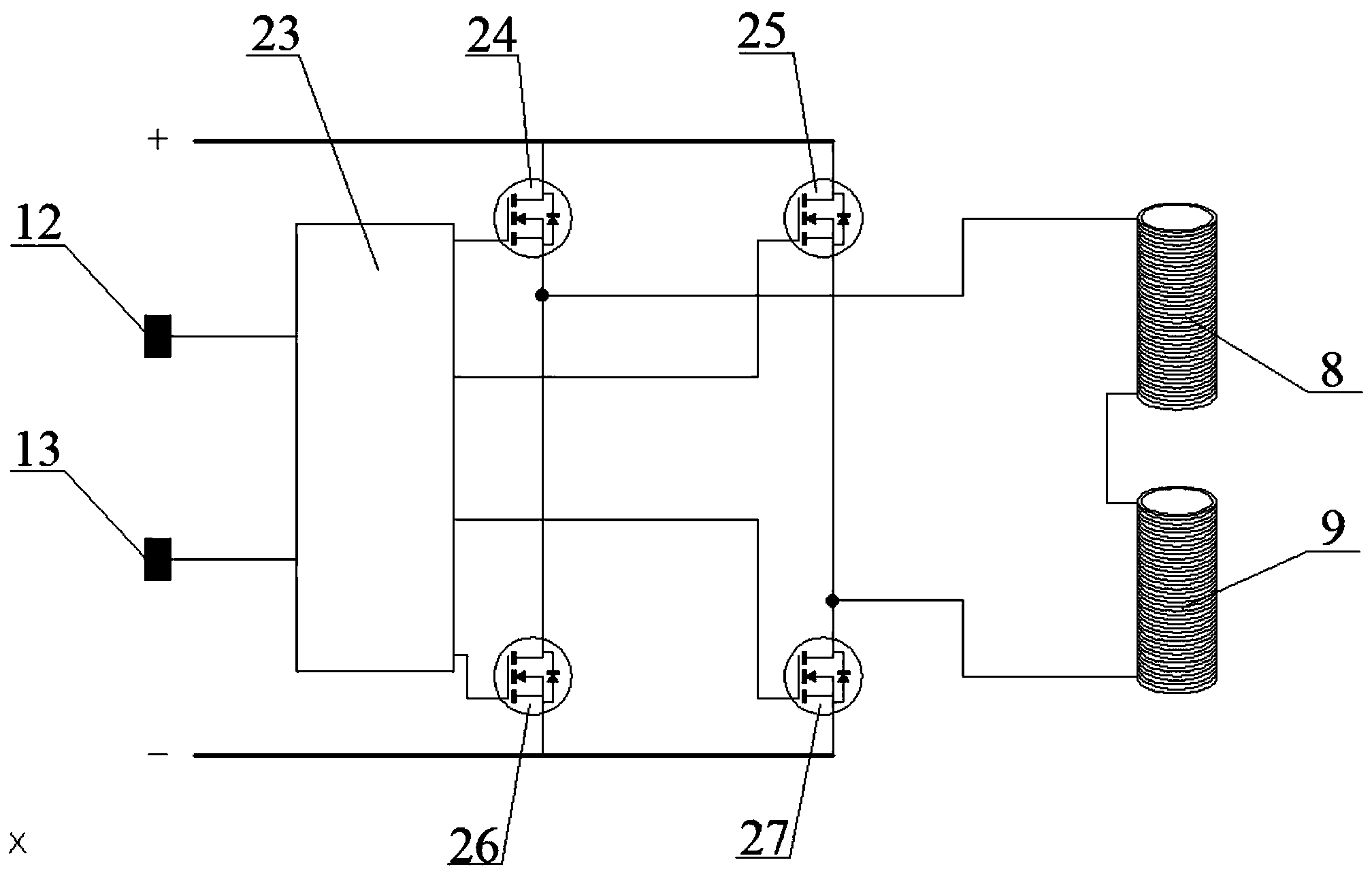

[0016] combine figure 1 , a bidirectional electromagnetic diaphragm pump according to the present invention, including basic components such as pump head, check valve, diaphragm, pump shaft, armature, coil, spring, pump casing, etc. Permanent magnets and Hall sensors. Pump head A, pump head B, and pump casing are located in a hollow cuboid structure composed of pump head A and pump head B. The four corners of the hollow structure are equipped with check valves A, A, One-way valve B, one-way valve C, one-way valve D, the pump casing is composed of two convex structures, one convex body has an inlet in the center of the bottom, and the other convex body has an outlet in the center of the bottom, and the middle of the two convex structures The pump shaft, the diaphragm A and the diaphragm B are connected at both ends of the pump shaft, the armature A and the armature B are symmetrically fixed on the pump shaft, the coil A and the coil B are respectively between the armature A, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com