Light-controlled winder

The technology of a bobbin and bobbin, which is applied to the field of sewing machines, can solve the problems of uncontrollable number of windings, easy wear and tear of the thread, reduced work efficiency, etc., so as to achieve a simple and reliable fixing structure, reduce the wear of the thread, and improve the production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

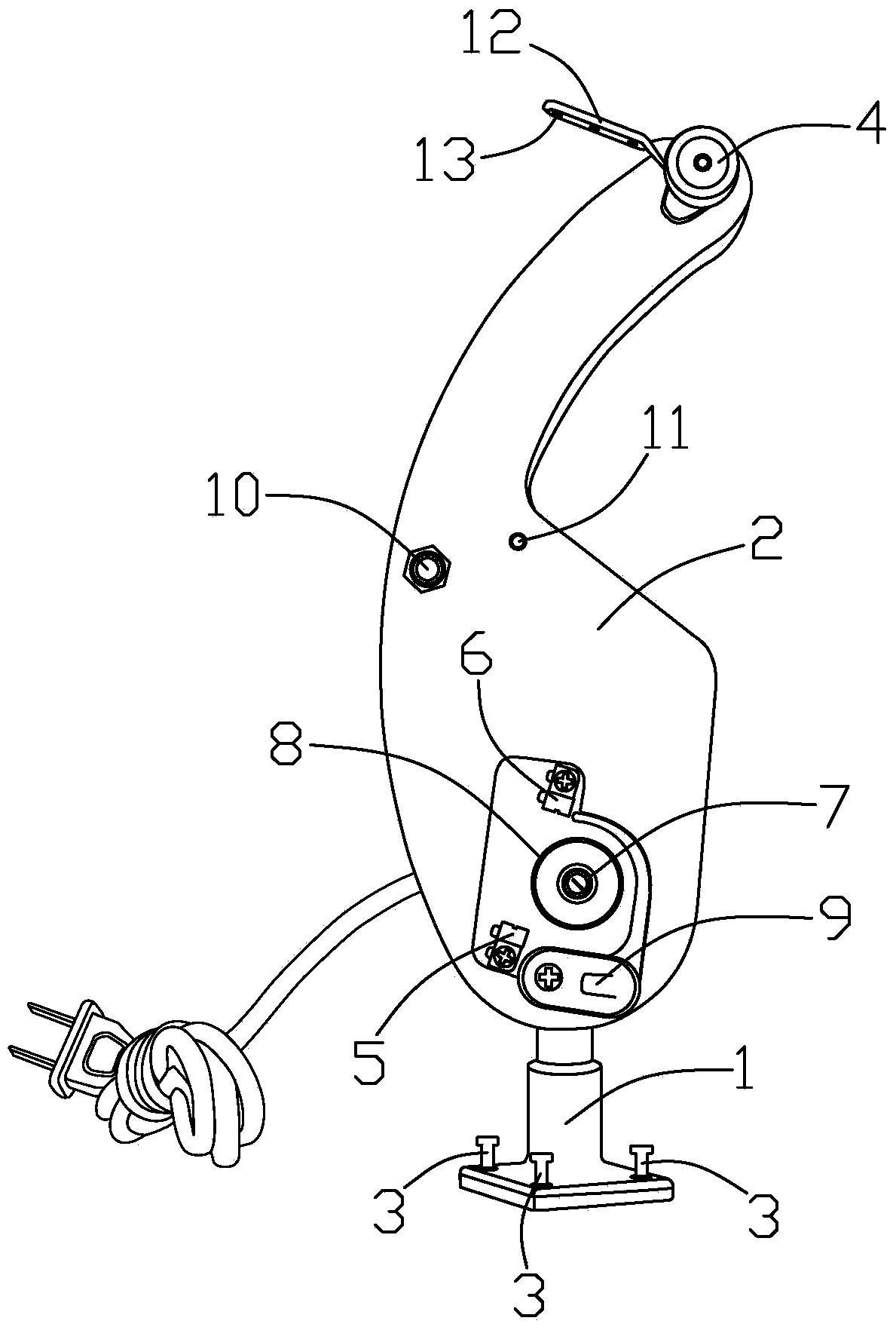

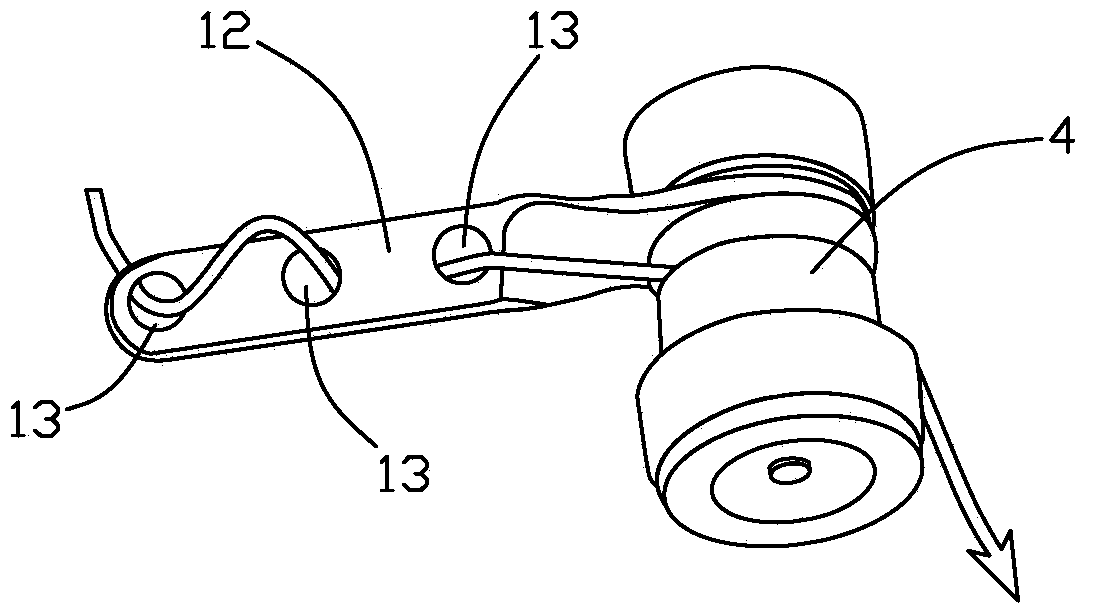

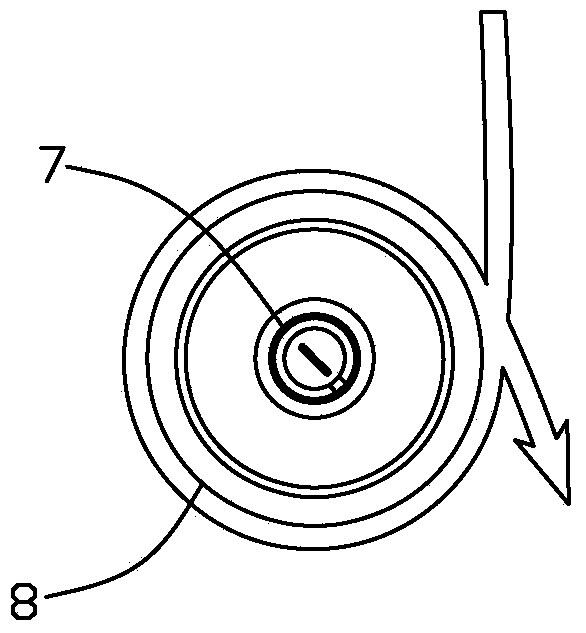

[0017] Such as Figure 1 to Figure 5 As shown, it is an optical control wire winder of the present invention, including a fixed base 1 and a winding frame 2, the fixed base 1 is fixedly connected with the winding frame 2, the fixed base 1 is provided with a base fixing screw 3, and the winding frame 2 Connected with an external power supply, the upper side of the bobbin frame 2 is provided with a thread clamp 4, the thread clamp 4 is provided with a clamp plate 12, and the clamp plate 12 is provided with at least two clamp holes 13 for sewing thread Thread and wind on the thread clamp hole 13, adjust the tension of the sewing thread, so that the sewing thread can be smoothly threaded on the thread clamp 4, so as to ensure that the winding process is carried out smoothly. One side of the lower end of the bobbin 2 is provided with a photoelectric transmitter 5 and a photoelectric receiver 6, the photoelectric transmitter 5 and the photoelectric receiver 6 are arranged opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com