Formaldehyde-removing coating capable of absorbing and decomposing dual functions and preparation method thereof

A dual-function, coating technology, applied in coatings and other directions, can solve the problem of no formaldehyde removal function, achieve good formaldehyde removal ability, enhance photocatalytic performance, solve the effect of agglomeration and difficult dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

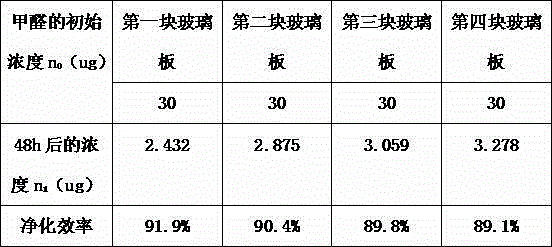

Examples

Embodiment 1

[0042] A coating capable of absorbing and decomposing dual-function formaldehyde removal. The coating is composed of the following components in weight percentage: 29% heavy calcium, 11% emulsion, 7% calcined kaolin, 8% washed kaolin, 6% titanium dioxide, and modified sea foam Stone / Nano TiO 2 Composite material 7%, dispersant 0.3%, wetting agent 0.4%, defoamer 0.2%, multifunctional additive 0.3%, antifungal agent 0.4%, film forming aid 0.4%, antifreeze agent 0.3%, bactericide 0.3 %, thickener 0.4%, water 29%. Its preparation method is as follows:

[0043] Modified sepiolite / nano-TiO 2 Preparation of composite materials:

[0044] A. Add 5g of sepiolite to a 250ml three-necked bottle, slowly add 100ml of ethanol, 12.5ml of tetrabutyl titanate, stir at a speed of 400r / min for 30min in a constant temperature water bath at 25°C, and then ultrasonically disperse for 30min to make the sepiolite and The solution is mixed evenly;

[0045] B. Add 0.1gGd 2 o 3 Dissolve in 1.5ml d...

Embodiment 2

[0055] A coating capable of absorbing and decomposing dual-function formaldehyde removal. The coating is composed of the following components in weight percentage: 27% heavy calcium, 12% emulsion, 9% calcined kaolin, 7% washed kaolin, 7% titanium dioxide, and modified sea foam Stone / Nano TiO 2 Composite material 7%, dispersant 0.4%, wetting agent 0.3%, defoamer 0.3%, multifunctional additive 0.2%, antifungal agent 0.3%, film forming aid 0.3%, antifreeze agent 0.5%, bactericide 0.2 %, thickener 0.5%, water 28%. Its preparation method differs from Example 1 in that modified sepiolite / nano TiO 2 Composite materials are prepared differently, while coatings are prepared in the same way.

[0056] This example modified sepiolite / nano-TiO 2 Preparation of composite materials:

[0057] A. Add 8g of sepiolite to a 250ml three-necked bottle, slowly add 130ml of ethanol, 20ml of tetrabutyl titanate, stir at a speed of 600r / min in a constant temperature water bath at 40°C for 22min, an...

Embodiment 3

[0062] A coating capable of absorbing and decomposing dual-function formaldehyde removal, the coating is composed of the following components in weight percentage: 30% heavy calcium, 15% emulsion, 10% calcined kaolin, 4% washed kaolin, 10% titanium dioxide, modified sea foam Stone / Nano TiO 2 Composite material 4%, dispersant 0.6%, wetting agent 0.1%, defoamer 0.2%, multifunctional additive 0.1%, antifungal agent 0.1%, film forming aid 0.6%, antifreeze agent 0.1%, bactericide 0.1 %, thickener 0.1%, water 25%. Its preparation method differs from Example 1 in that modified sepiolite / nano TiO 2 Composite materials are prepared differently, while coatings are prepared in the same way.

[0063] This example modified sepiolite / nano-TiO 2 Preparation of composite materials:

[0064] A. Add 8g of sepiolite to a 250ml three-necked bottle, slowly add 130ml of ethanol, 20ml of tetrabutyl titanate, stir at a speed of 600r / min in a constant temperature water bath at 40°C for 22min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com