Manual operation liquid discharge device

A discharge device and liquid technology, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of joint shedding, pipe wall corrosion, high material temperature, prolong service life, improve corrosion resistance and temperature resistance , the effect of preventing safety risks and environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

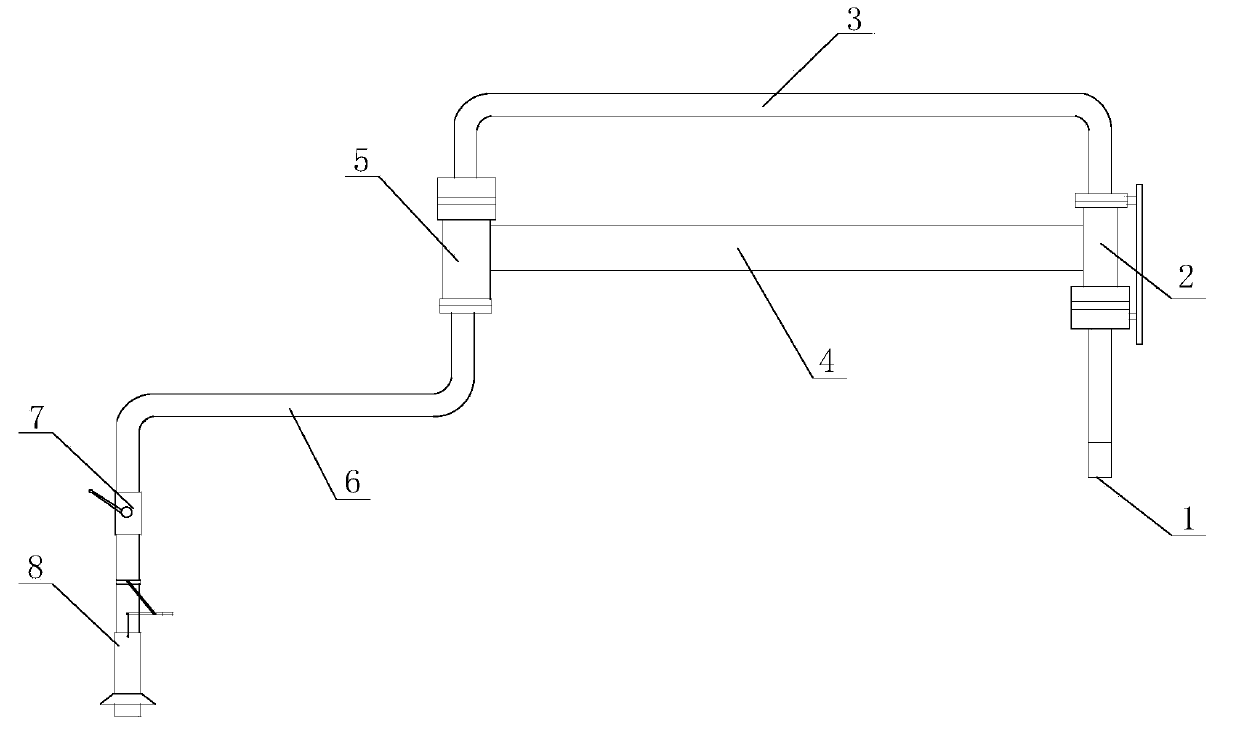

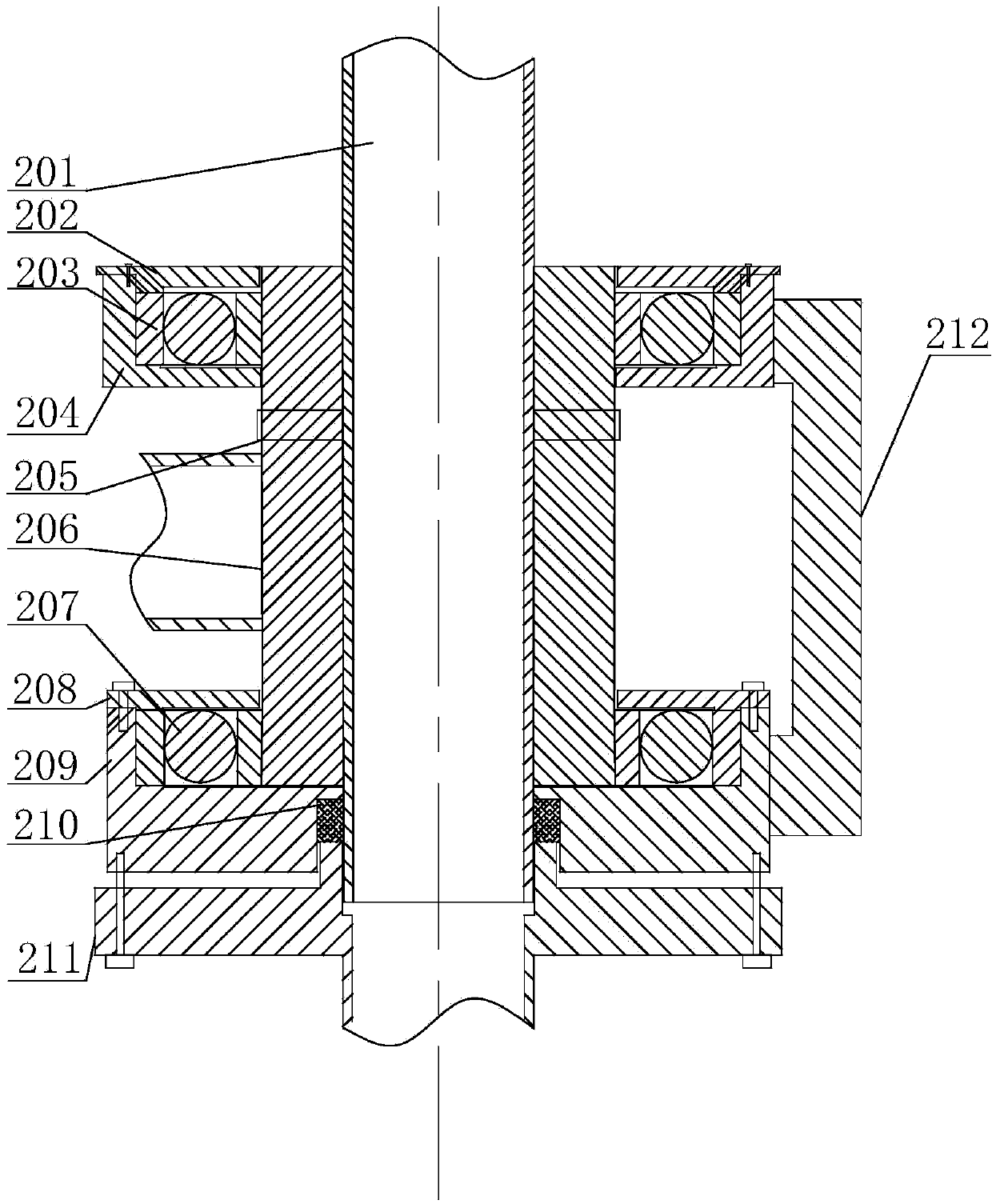

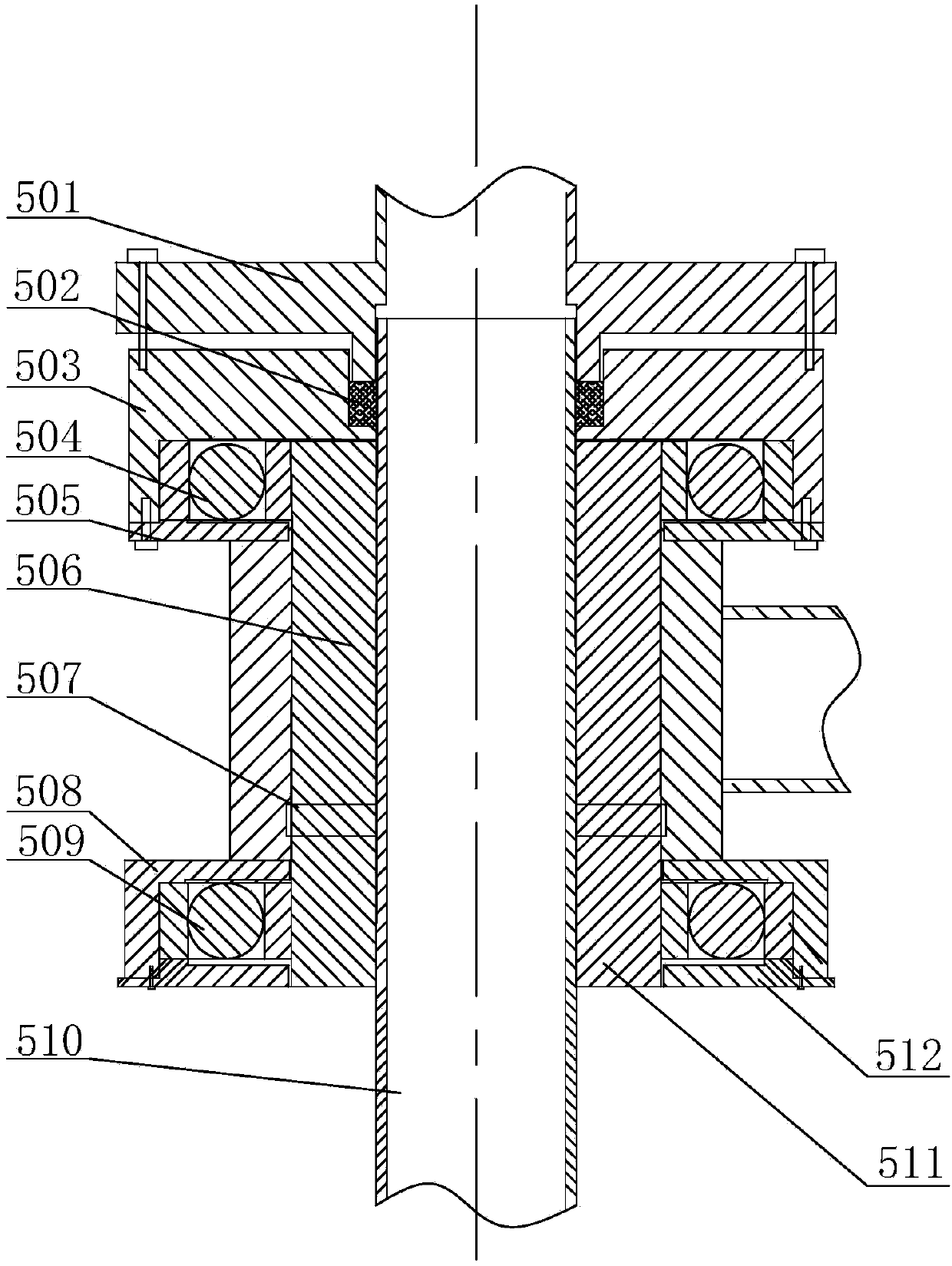

[0029] Such as figure 1 As shown, this embodiment discloses a manual liquid discharging device, which includes a feed port 1, a primary universal joint 2, an upper rotating arm 3, a rotary arm 4, a secondary universal joint 5, and a lower rotary joint. Arm 6, manual control ball valve 7, lifting device 8. The feed port 1 is connected to the upper rotating arm 3 through the primary universal joint 2, the upper rotating arm 3 is connected to the lower rotating arm 6 through the secondary universal joint 5, and the lower rotating arm 6 is connected through the manual control ball valve 7 There are lifting devices 8. The upper rotating arm 3 and the rotating big arm 4, the secondary universal joint 5, the lower rotary arm 6, the manual control ball valve 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com