High-speed double-station-rechecking-type weighing quantifying filling machine

A filling machine, high-speed technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as unqualified product filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

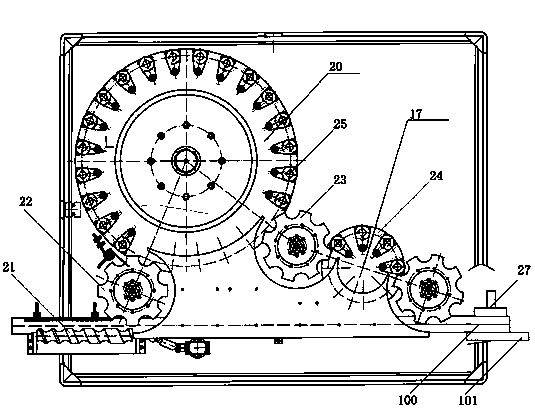

[0016] The power transmission mechanism 1 composed of a motor, a reducer and gears drives the main rotary table 20, the bottle feeding screw 21, the bottle in and out star wheel 22, the rotary rotary table 23 and the recheck rotary table 24 to rotate.

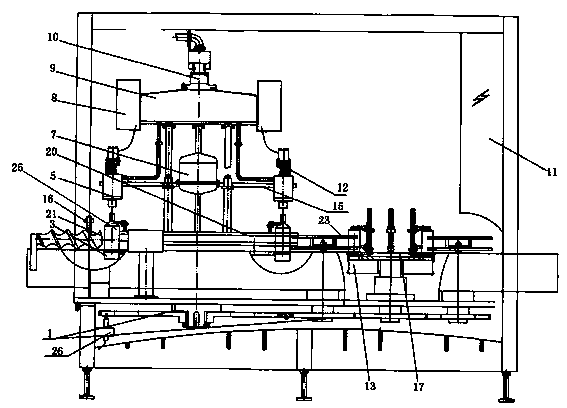

[0017] Its filling valve 5, gas distribution assembly 7, sub-electrical control cabinet 8, liquid cylinder assembly 9, rotary wine feeding assembly 10, valve opening and closing execution cylinder 12, etc. are installed on the mounting plate 15, together with the main rotary table 20 turn.

[0018] The control adopts PLC control, and the operation interface adopts touch screen. Data transmission from the main control cabinet 11 to the rotating distribution control cabinet 8 adopts PROFIBUS-DP communication technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com