Non-powered bogie for meter-gauge track

A bogie, non-powered technology, applied in the field of rail vehicles, can solve the problems that the bogie is unfavorable for the vehicle to pass the small-radius curve line, and the maintenance and installation of the bogie are inconvenient, so as to reduce the distance between the axles, prevent interference, facilitate installation and The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

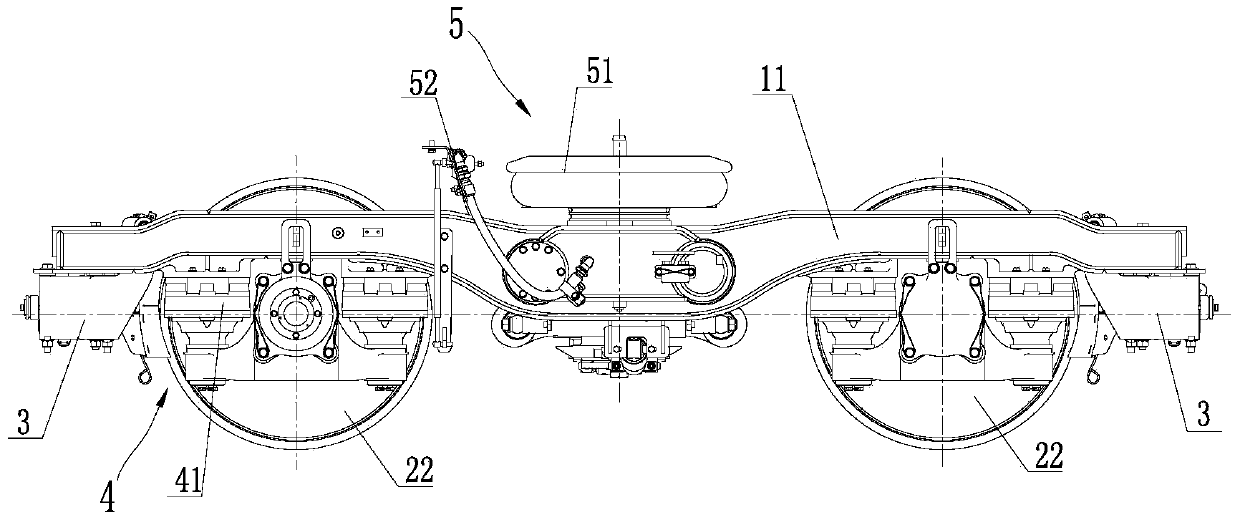

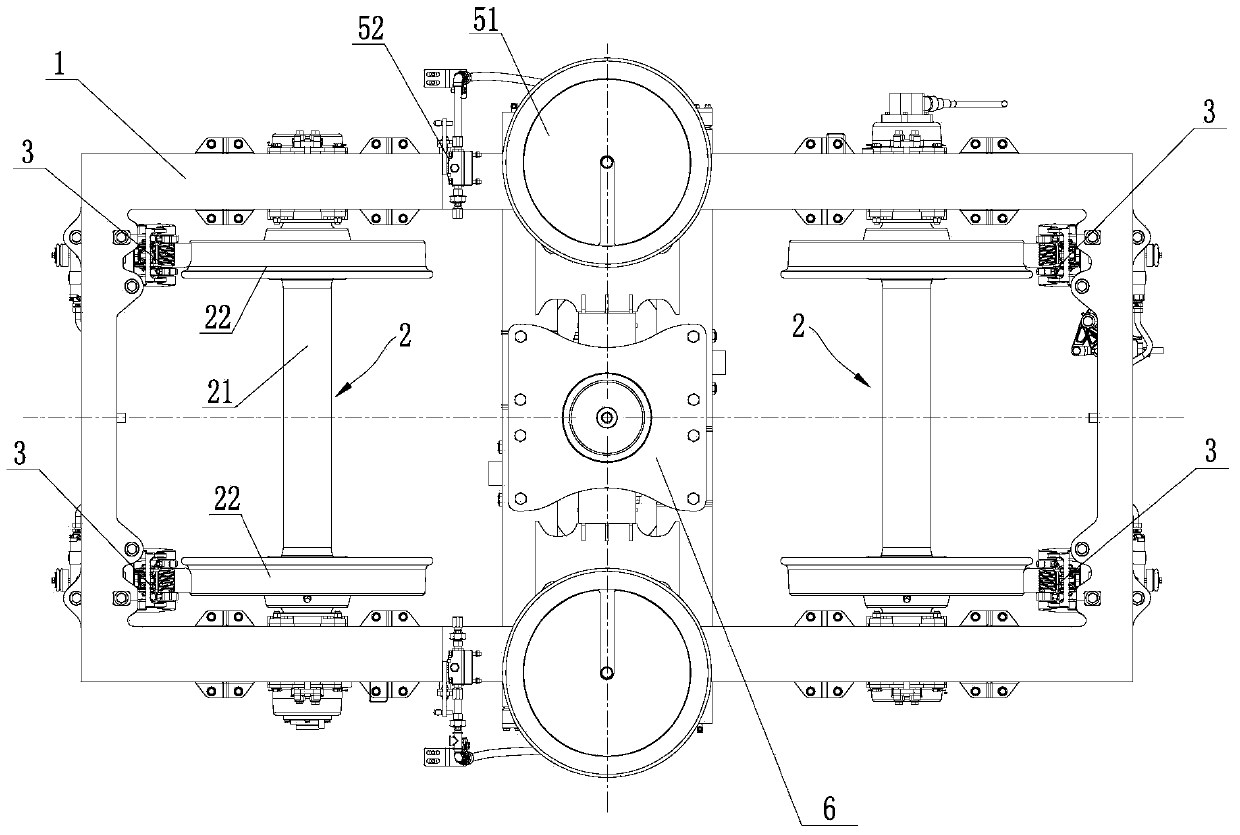

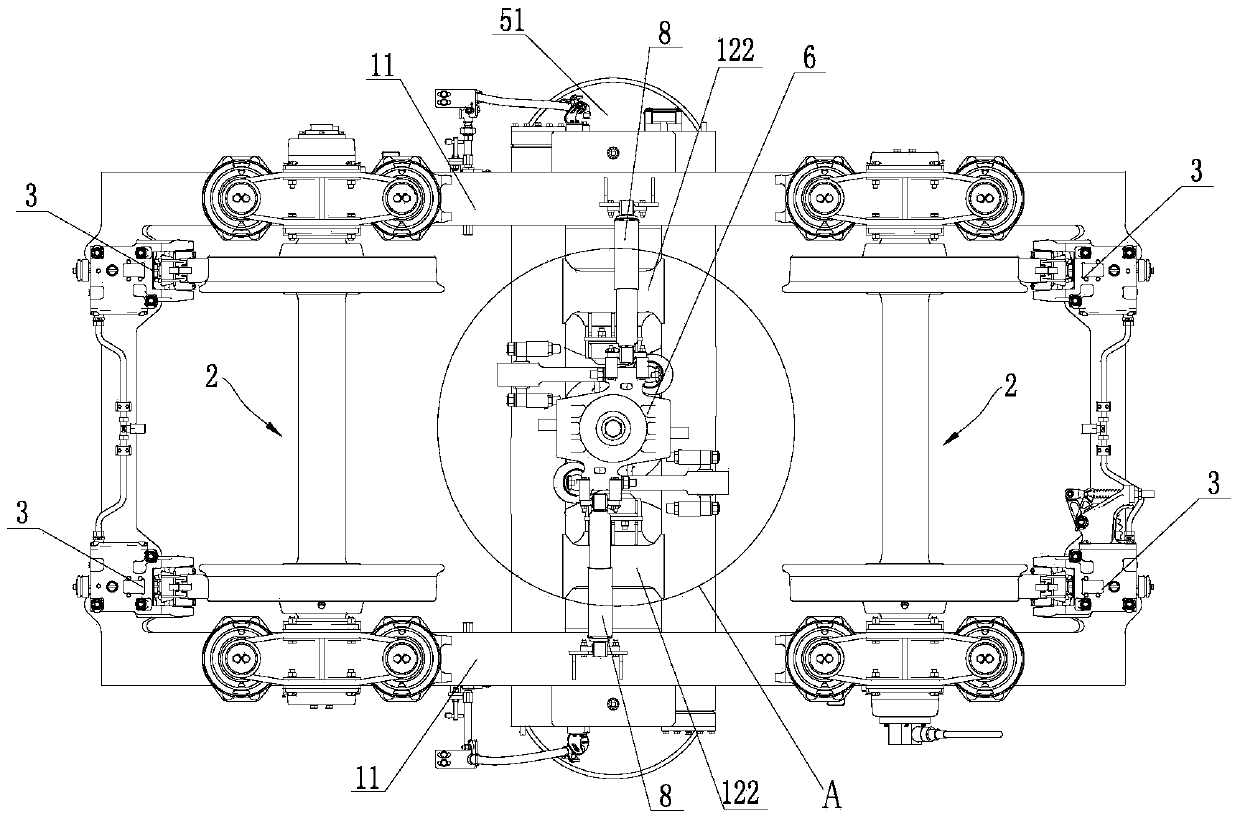

[0015] An embodiment of the present invention provides a non-powered bogie for a meter-gauge line, such as figure 1 and figure 2 As shown, the non-power bogie for the meter-gauge line includes a bogie frame 1, and two wheel sets 2 are arranged in parallel on the bogie frame 1, wherein each wheel set 2 includes an intermediate shaft 21 and two wheels 22; The sides of the two wheel sets 2 facing away from each other correspond to the position of each wheel 22 in the wheel set 2, and a tread braking device 3 is respectively provided for braking each wheel 22, wherein the tread braking device 3 The devices known to those skilled in the art to perform braking by friction between the brake shoe and the tread of the moving vehicle wheel will not be repeated here. In this embodiment, the tread braking device 3 is arranged on the side away from the two wheelsets 2, compared to being arranged on the opposite side of the two wheelsets 2, the installation and maintenance are more conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com